22 | Maintenance LM Series Heat Pump

LM Series Heat Pump8 733 905 315 (2013/9) Subject to change without prior notice

3. Lubrication of the blower motor is not

required, however may be performed on some

motors to extend motor life. Use SAE-20 non-

detergent electric motor oil.

4. The condensate drain should be checked

annually by cleaning and flushing to insure

proper drainage.

5. Periodic lockouts almost always are caused by

air or water flow problems. The lockout

(shutdown) of the unit is a normal protective

measure in the design of the equipment. If

continual lockouts occur call a mechanic

immediately and have them check for: water

flow problems, water temperature problems,

air flow problems or air temperature problems.

Use of the pressure and temperature charts for

the unit may be required to properly determine

the cause.

Access to Internal Components for

Vertical (VT) Units

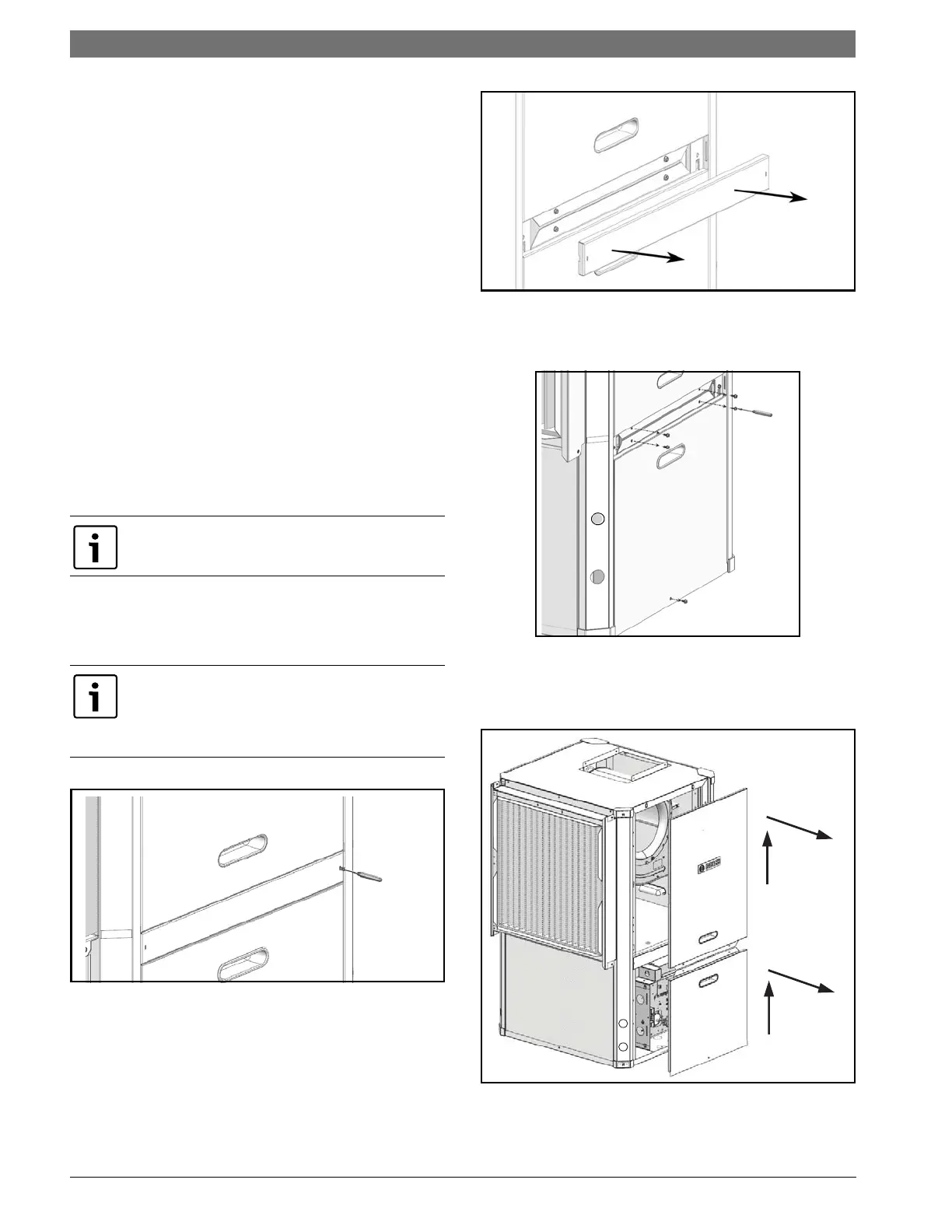

1. Using a Flat screw driver remove and retain

Panel Belt by inserting the screwdriver into the

slot and releasing the catch. (Figures #17 and

#18)

Figure # 17

Figure # 18

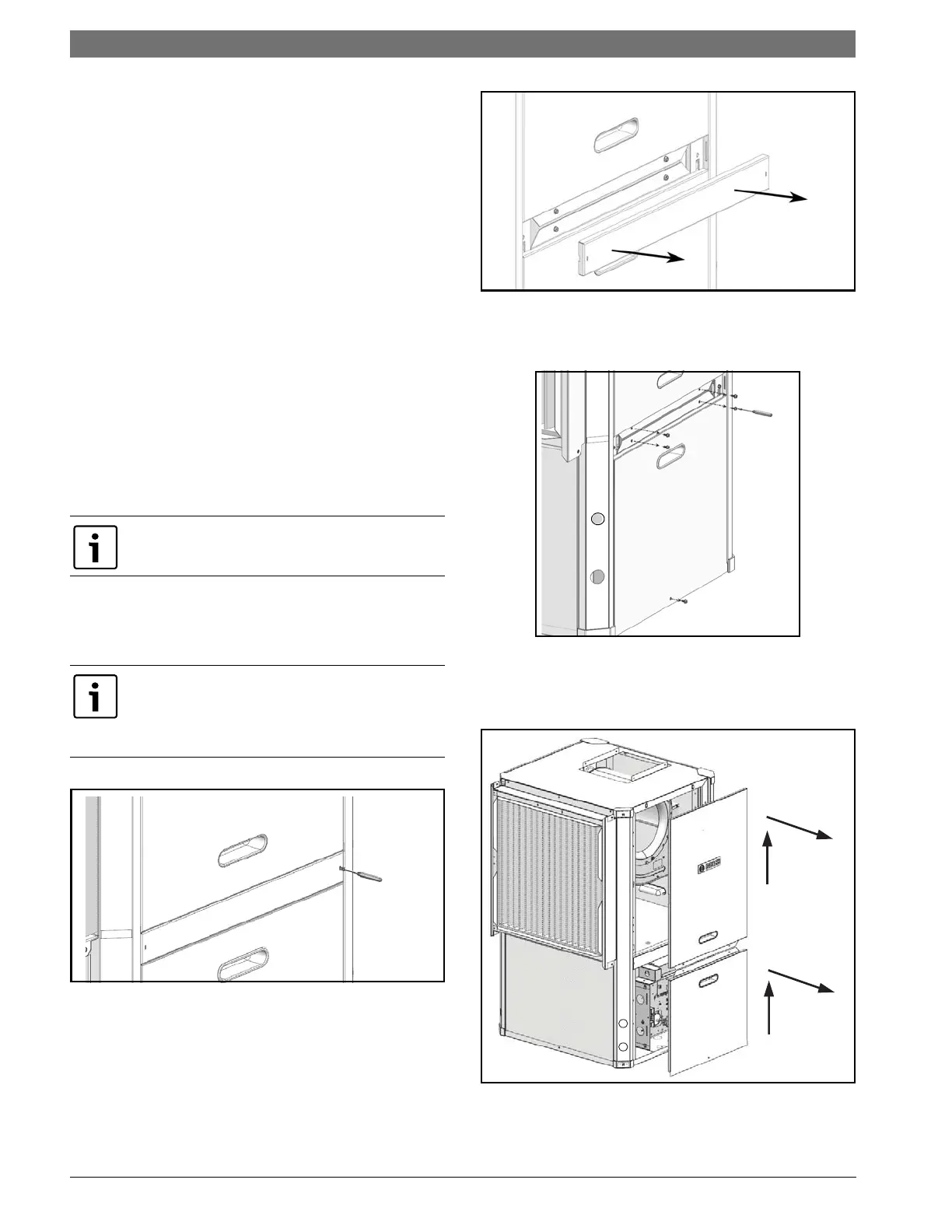

2. Remove and retain lower panel by removing

(3)three screws. (Figure #19)

Figure # 19

3. Remove and retain upper panel by lifting up

and out as shown in Figure #20.

Figure # 20

4. Repeat steps 1–3 for other sides as necessary.

See LM IOM for further reference. Manual is

located inside of the unit.

Heat pumps are supplied with panel belt which

needs to be removed to access screws for panel

removal. The belt is held in place by a clip on

one side and an interference fit on the other end.

Loading...

Loading...