Page 25

Roll Stop Adjustment Instructions

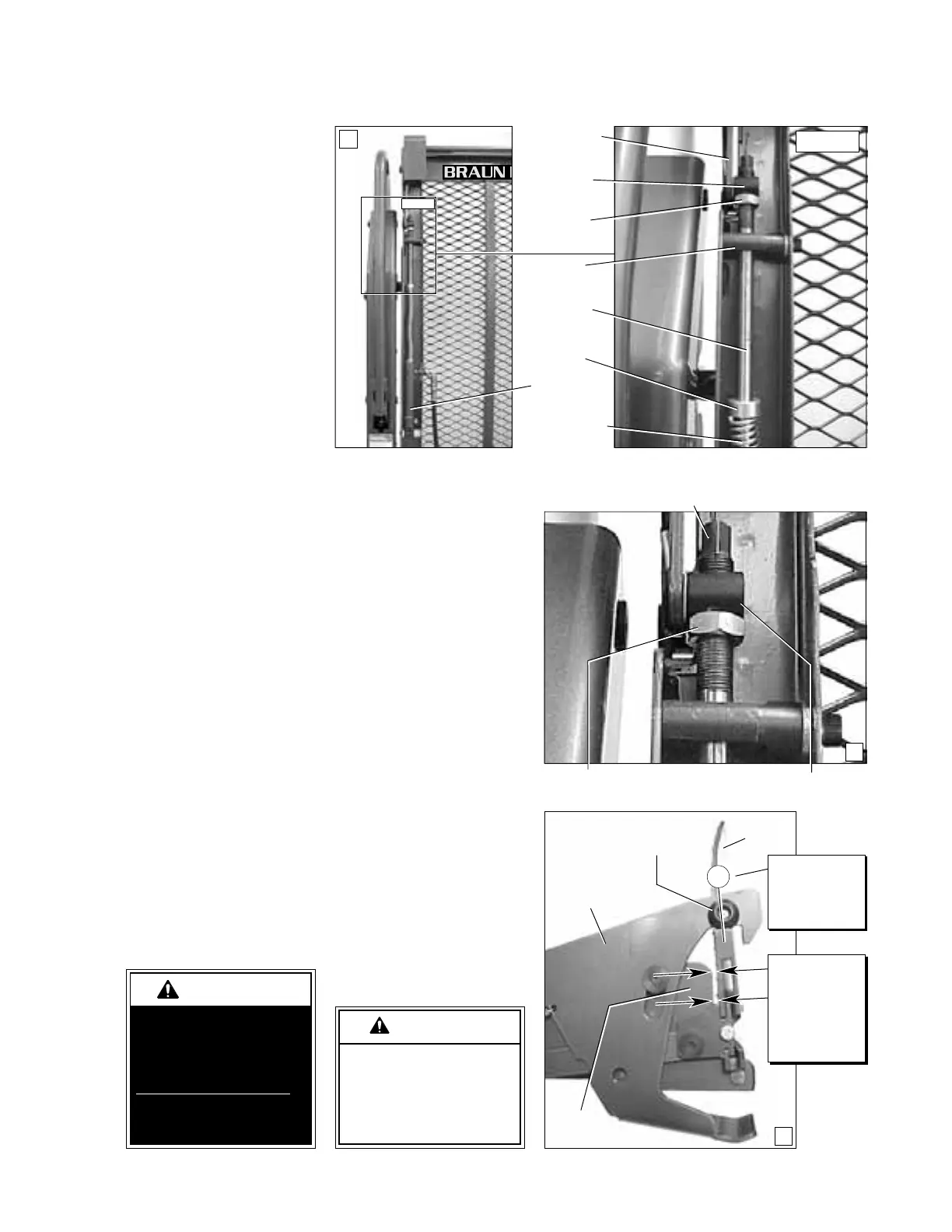

When replacing a roll stop

or roll stop hydraulic

cylinder, the roll stop must

be properly adjusted during

installation procedures.

The roll stop cylinder rod

must be adjusted to

properly position the roll

stop. Failure to do so may

result in lift damage. Read

warning posted below.

With the lift in the stowed

position (cylinder must be

fully retracted), adjust the

cylinder rod to achieve

proper roll stop position.

Carefully loosen (back off)

the 1/2" jam nut positioned

below the roll stop lever

adapter.

Adapter

Roll Stop

Cylinder

Cylinder

Rod

Jam Nut

Pivot

Roll Stop

Latch Lever

CAUTION

Roll stop contact with

platform side plates

will result in roll stop

damage.

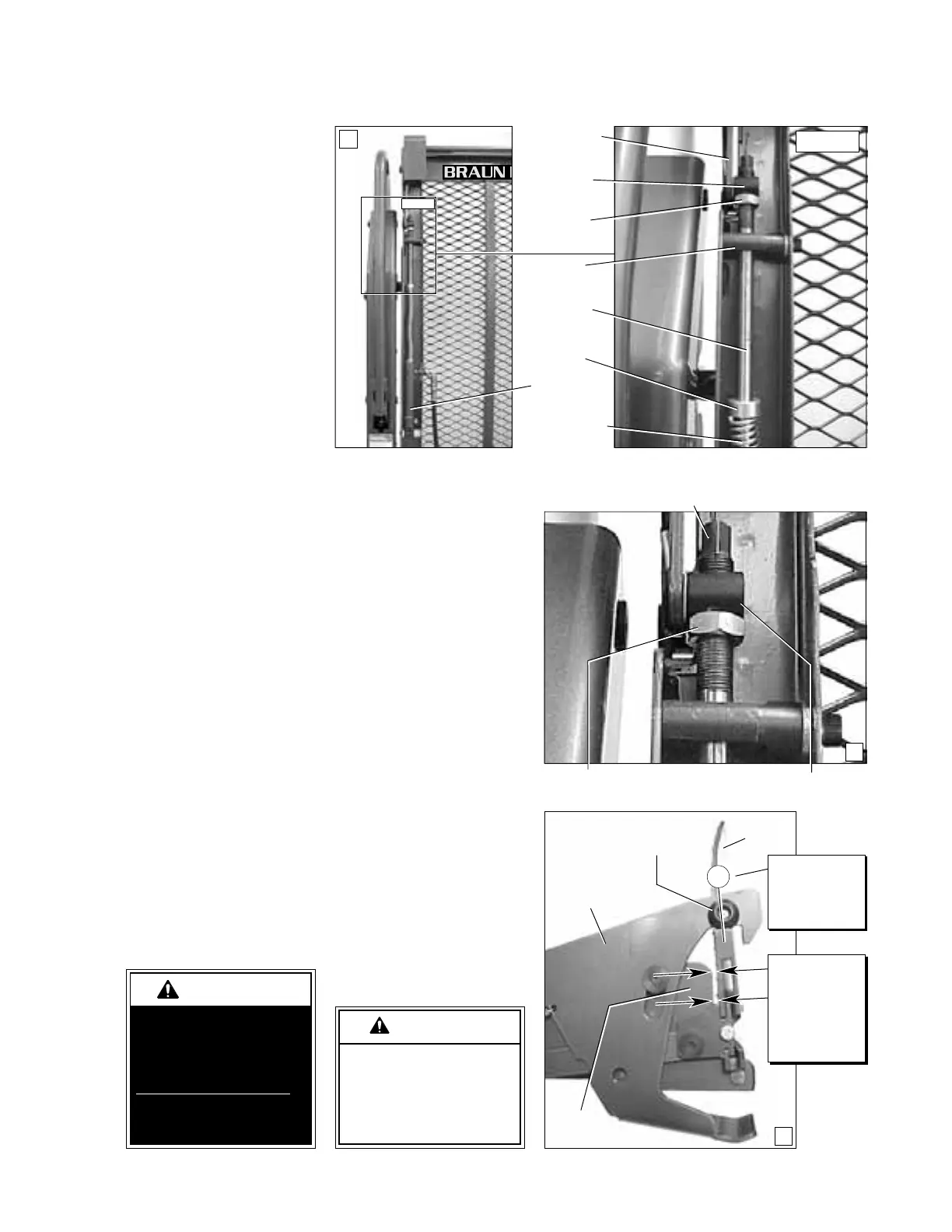

Carefully turn the cylinder rod in or out of the

threaded adapter to position the roll stop as detailed

below.

Caution: Grip the square head at the end of the roll

stop cylinder rod (see Photo B). Do not grip the

smooth portion of the rod. Doing so can damage the

rod which can result in failure of the rod to move

freely in and out of the roll stop cylinder pivot. The roll

stop may not operate properly under this condition.

Roll Stop Positioning

A. Roll stop must be centered below latch-mounted

rubber bumper. See Photo C.

B. Roll stop must be parallel (aligned) with end of

platform side plate. See Photo C.

Caution: Do not allow the roll stop to contact the

platform side plates. Roll stop damage will occur.

Roll Stop

Latch

Roll

Stop

Rubber

Bumper

Platform

Side Plate

Compression

Spring

Collar

Grip square head to turn the cylinder rod.

Detail

Detail

A

B

C

Jam Nut Lever Adapter

W

A

RNING

Adjust roll stop as

specified. Failure to

do so may result in

serious bodily injury

and/or property dam-

age.

A. Center roll

stop below

rubber

bumper.

B. Roll stop

must be

parallel

(aligned)

with end of

side plate.

C

L

Loading...

Loading...