18 www.brutepower.com

Maintenance

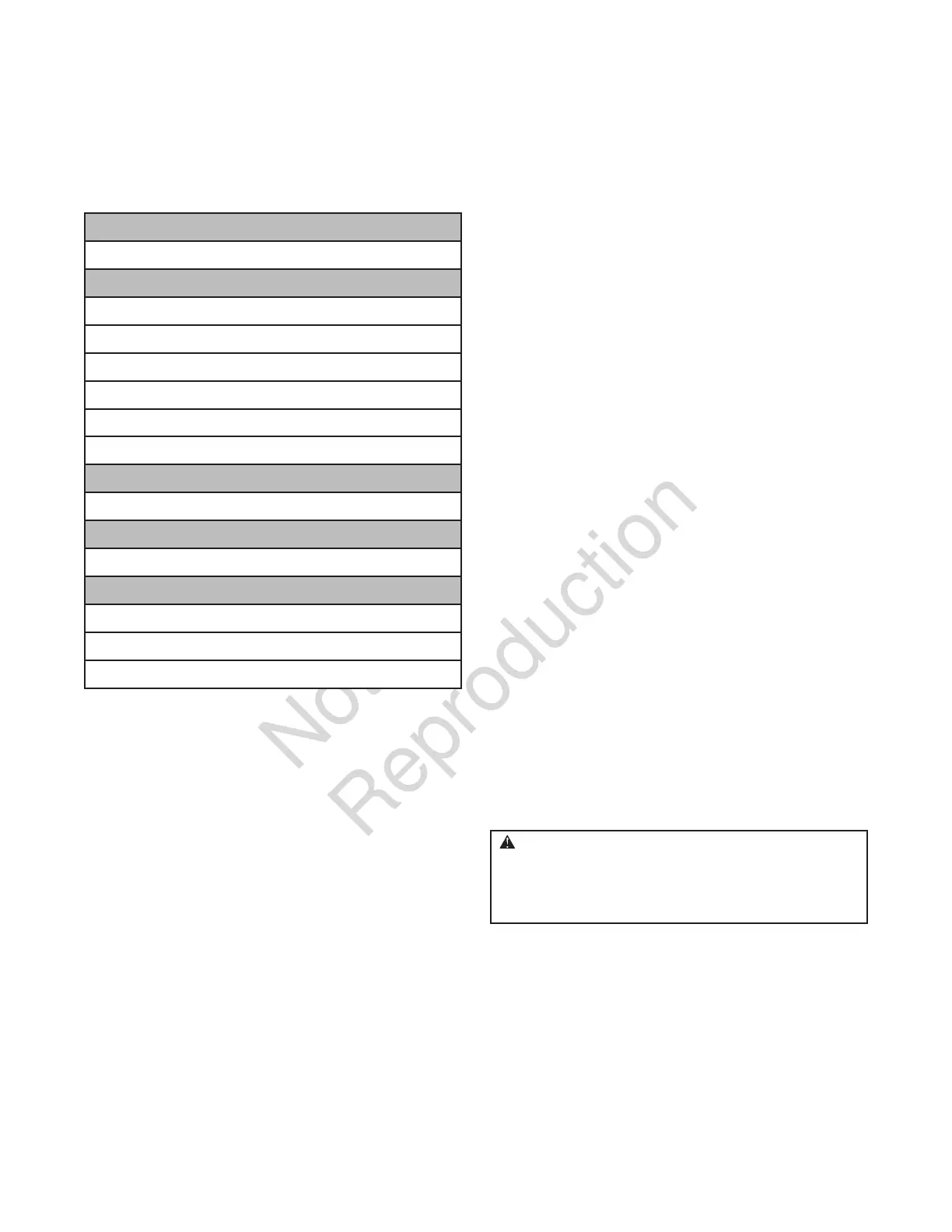

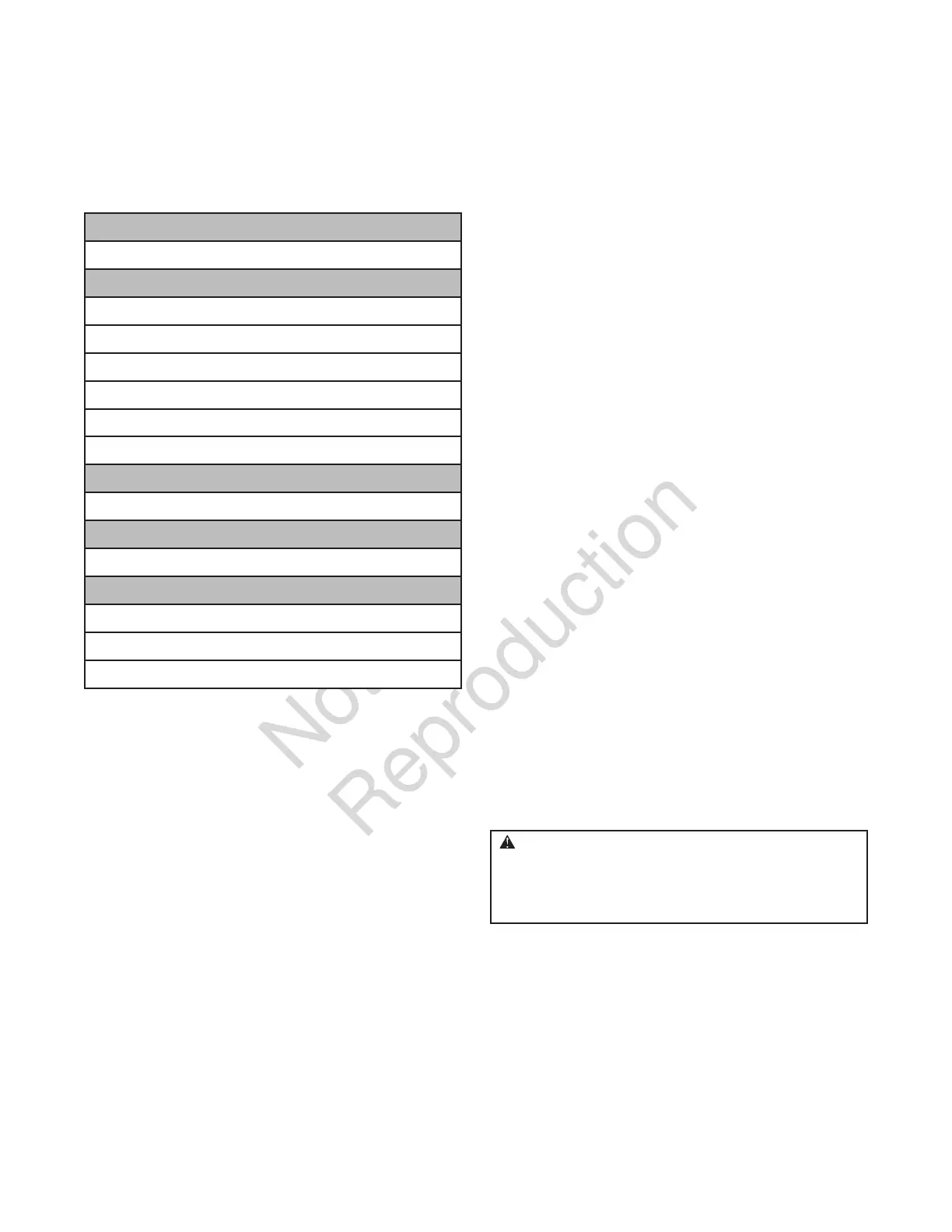

Maintenance Schedule

Follow the hourly or calendar intervals, whichever

occurs rst. More frequent service is required when

operating in adverse conditions noted below.

1

Clean if clogged. Replace if perforated or torn.

2

Service more often under dirty or dusty conditions.

General Recommendations

Regular maintenance will improve the performance

and extend the life of the pressure washer. See any

qualied dealer for service.

The pressure washer’s warranty does not cover

items that have been subjected to operator abuse or

negligence. To receive full value from the warranty,

the operator must maintain the pressure washer as

instructed in this manual, including proper storage as

detailed in Winter Storage and Long Term Storage.

NOTICE Should you have questions about replacing

components on your pressure washer, please call

(800) 743-4115 for assistance.

Some adjustments will need to be made periodically to

properly maintain your pressure washer.

All service and adjustments should be made at least

once each season. Follow the requirements in the

Maintenance Schedule chart above.

NOTICE Once a year you should clean or replace the

spark plug, clean or replace the air lter, and check the

spray gun and nozzle extension assembly for wear. A

new spark plug and clean air lter assure proper fuel-

air mixture and help your engine run better and last

longer.

Pump Oil

DO NOT attempt any oil maintenance on this pump.

The pump is pre-lubricated and sealed from the

factory, requiring no additional maintenance for the life

of the pump.

Emissions Control

Maintenance, replacement, or repair of the

emissions control devices and systems may

be performed by any non-road engine repair

establishment or individual. However, to obtain

“no charge” emissions control service, the work must

be performed by a factory authorized dealer. See the

Emissions Warranty.

Before Each Use

1. Check engine oil level.

2. Clean debris.

3. Check water inlet screen for damage.

4. Check high pressure hose for leaks.

5. Check detergent siphoning tube and tank for

damage.

6. Check spray gun and nozzle extension for leaks.

7. Rinse out garden hose to ush out debris.

Battery Maintenance

Other than oat charging, described elsewhere, no

maintenance is required for the starting battery. Keep

the battery and terminals clean and dry.

NOTICE Battery charging should be performed in a

dry location, such as inside a garage.

Fuel Valve Maintenance

The fuel valve is equipped with a fuel sediment cup,

screen, and o-ring that need to be cleaned.

1. Move fuel valve to OFF (0) position.

2. Remove sediment cup (A) from fuel valve.

Remove o-ring (B) and screen (C) from fuel valve.

First 5 Hours

• Change engine oil

Every 8 Hours or Daily

• Check/clean water inlet screen

1

• Check high pressure hose

• Check detergent siphoning tube/tank

• Check spray gun and assembly for leaks

• Clean debris

• Check engine oil level

Every 25 Hours or Yearly

• Service engine air cleaner

2

Every 50 Hours or Yearly

• Change engine oil

2

Every 100 Hours or Yearly

• Service spark plug

• Inspect muer and spark arrester

• Clean cooling system

2

WARNING Battery posts, terminals and related

accessories contain lead and lead compounds -

chemicals known to the State of California to cause

cancer and reproductive harm. Wash hands after

handling.

Loading...

Loading...