To charge refrigerant into the evaporator, fill clean solu-

tion containers with the distilled or deionized water. Charge

the water through the refrigerant pump service valve, fol-

lowing the appropriate steps in Charging Solution section.

Charge in at least the amount listed in Table 3 under Ini-

tial Refrigerant amount. This charge must be adjusted after

start-up to achieve optimal Cycle-Guard™ control condi-

tions to limit the maximum solution concentration (which

prevents solution crystallization). However, any extra re-

frigerant should be limited because the normal refrigerant

pump discharge pressure is below atmospheric pressure and

a vacuum bottle is required to remove refrigerant (see Final

Refrigerant Charge Adjustment section, page 25).

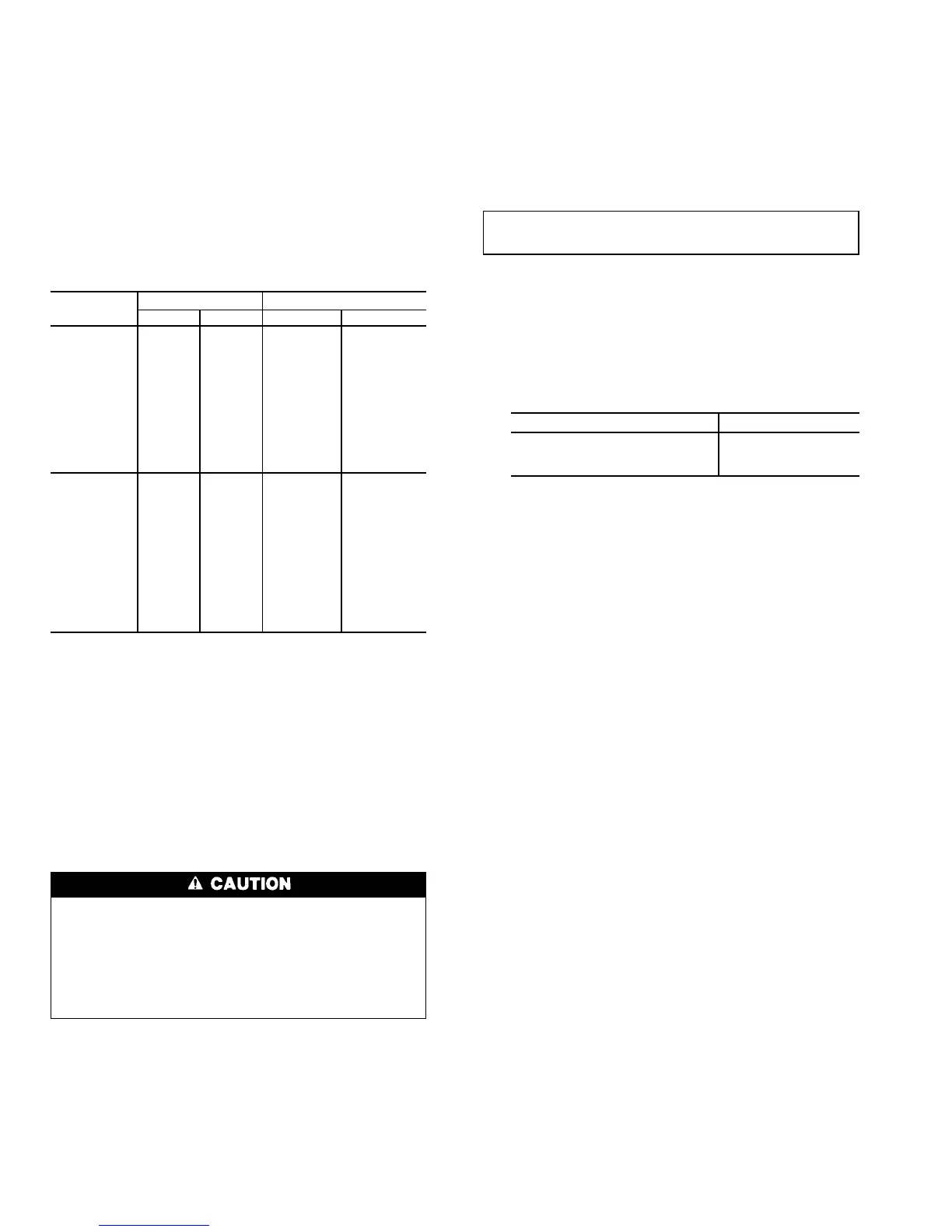

Table 3 — Nominal Machine Charges*

UNIT

16JT

LiBr SOLUTION INITIAL REFRIGERANT

Gal Kg Gal Kg

810,812,814 137 840 87 330

816,818,821 200 1225 106 400

824 246 1505 92 350

828 257 1575 92 350

832 309 1890 114 430

836 314 1925 114 430

841 366 2240 137 520

847 400 2450 137 520

854 440 2695 165 625

857 463 2835 165 625

865 514 3150 203 770

873 560 3430 232 880

880 623 3815 285 1080

080 754 4620 177 670

090 846 5180 201 760

100 903 5530 215 815

110 1017 6230 202 765

120 1097 6720 206 780

135 1263 7740 238 900

150 1377 8435 271 1025

080L 823 5040 197 745

090L 922 5650 211 800

100L 1006 6160 225 850

110L 1114 6825 219 830

120L 1200 7350 238 900

135L 1380 8450 277 1050

150L 1504 9210 304 1150

*Based on 55% concentration of solution, 44 F (7 C) leaving chilled water,

85 F (29 C) entering condensing water.

INITIAL CONTROL CHECKOUT

AND ADJUSTMENT

The checkout procedures in this section are for semi-

automatic control systems. The purpose of the checkout is to

ensure that control circuits have not been affected by ship-

ping or installation damage or altered in the process of mak-

ing field wiring connections.

NOTE: Some thermoswitch adjustments are scaled in Cel-

sius, hence that is the temperature stated first in some of the

instructions in this manual.

Follow the checkout sequence in detail. Machine must

be charged with solution and refrigerant before starting

checkout. Chilled water and condensing water circuits

must be filled and operative, but the manual steam or

hot water valve must remain closed.

Do not rotate hermetic pumps until machine is charged

with lithium bromide-water solution and refrigerant.

Preparation

1. Open the control panel and place the main circuit breaker

in OFF position (Fig. 13) to deenergize the control circuit

and pump motor.

2. Disconnect leads for solution pump motor and refriger-

ant pump motor at secondary starter terminals. Wrap the

ends of the disconnected wires with electrical tape and

mark for proper identification at reinstallation.

3. If starters for condensing water pump and chilled water

pump are operated by manual start-stop, temporarily place

an insulated jumper between terminals P1 and P2 to over-

ride the external interlock. Remove fuses from starters

for the condensing water pump motor and chilled water

pump motor. (Starters for these motors are field supplied

on external voltage lines and are not located in control

panel.)

If condensing and chilled water flow switches are used,

manually block the switches closed.

IMPORTANT: Do not open manual steam or hot

water valves.

Energize Control Circuit

1. Place the main circuit breaker in the ON position to en-

ergize control circuit. (Stop light turns red.)

2. Depress the Stop button to clear any safety fault condi-

tions and to prepare the control circuit for starting.

3. Place the control panel settings in the following

positions:

SETTINGS POSITION

Capacity Control AUTO.

Cycle Guard Switch AUTO.

Local/Remote Switch LOCAL

4. Depress the Start button momentarily to start the ma-

chine. The Run light turns green and the start cycle be-

gins.With normal operation, the solution pump starts im-

mediately and the refrigerant pump starts after about

5 minutes.

Check Solution and Refrigerant Pump

Starters

1. Make sure the solution and refrigerant pump starters are

energized.

2. Depress the Stop button momentarily (Run light de-

energizes). Both starters remain energized for approxi-

mately 15 minutes during dilution cycle (Dilution light

energizes).

Check Pump Starter Overloads

1. Depress the Start button, and wait for the pumps to start.

2. Push the trip bar on the side of the refrigerant pump starter

overload. All pump starters deenergize, the alarm buzzer

sounds, and the fault light identifies the fault category.

3. Depress the Stop button (to silence the alarm) and the

starter reset bar.

4. Repeat Steps1-3with other control panel starters. Refer

to the wiring diagrams for the set point of each starter.

5. Starters for auxiliary equipment must be similarily checked,

according to the manufacturers’ instructions.

Check Low-Temperature Cutout

1. Turn the differential adjustment screw until differential

set point is at 4 C (7.2 F).

2. Place control sensing bulb in a water bath maintained at

9° F (5° C) below design leaving chilled water tempera-

ture (but not below 36 F [2 C]). This is the correct low-

temperature cutout setting.

3. Depress the Start button.

Slowly turn cutout adjustment knob clockwise until con-

tacts open. Chilled water, condensing water, solution and

refrigerant pump starters, and Run light should de-

energize, the alarm buzzer should sound, and the fault

light should identify the fault category.

22

Loading...

Loading...