Actions After Abnormal Shutdown — Abnormal

stop occurs automatically when any of the safety devices in

Table 8 sense a condition which might be potentially dam-

aging to the chiller. When this happens the steam valve closes

completely, the alarm buzzer sounds, and the type of prob-

lem is indicated by one of the three fault lights. Also, both

the Stop and Run lights will be on.

The buzzer can be silenced and the circuit reset for restart

by depressing the Stop button, but this should be done only

after noting which fault light is on; or the alarm buzzer stop

button may be depressed to silence the buzzer while the con-

trol circuit remains in a shutdown alarm mode for trouble-

shooting. If the fault is a type which does not allow shut-

down dilution, the condition should be corrected and the chiller

either restarted, or started and stopped for normal

dilution, as quickly as possible to avoid solution crystalli-

zation when the machine cools down.

Actions After Power Interruption — If the control

power is interrupted during operation, the chiller stops im-

mediately without the normal shutdown sequence and dilu-

tion. The capacity control valve might be open so the steam

supply valve should be closed immediately.

Solution crystallization can occur if the concentration is

high (e.g., chiller was operating with a relatively large load).

If so, depress the Start button to restart the machine as soon

as possible after the power is restored. The machine will not

restart automatically when power is recovered. If the chiller

cannot be operated because of crystallization, follow the de-

crystallization instructions in the Maintenance Procedures sec-

tion, page 40.

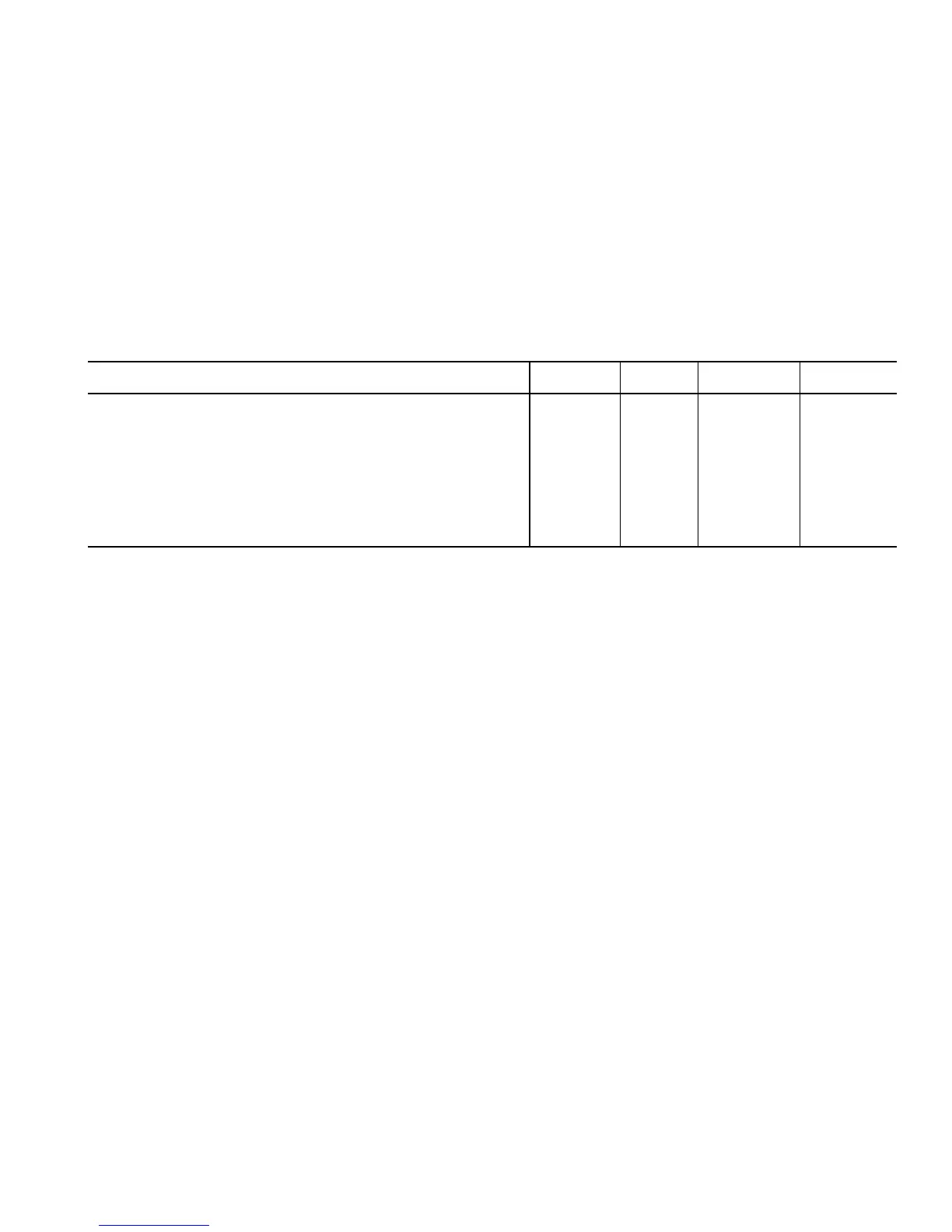

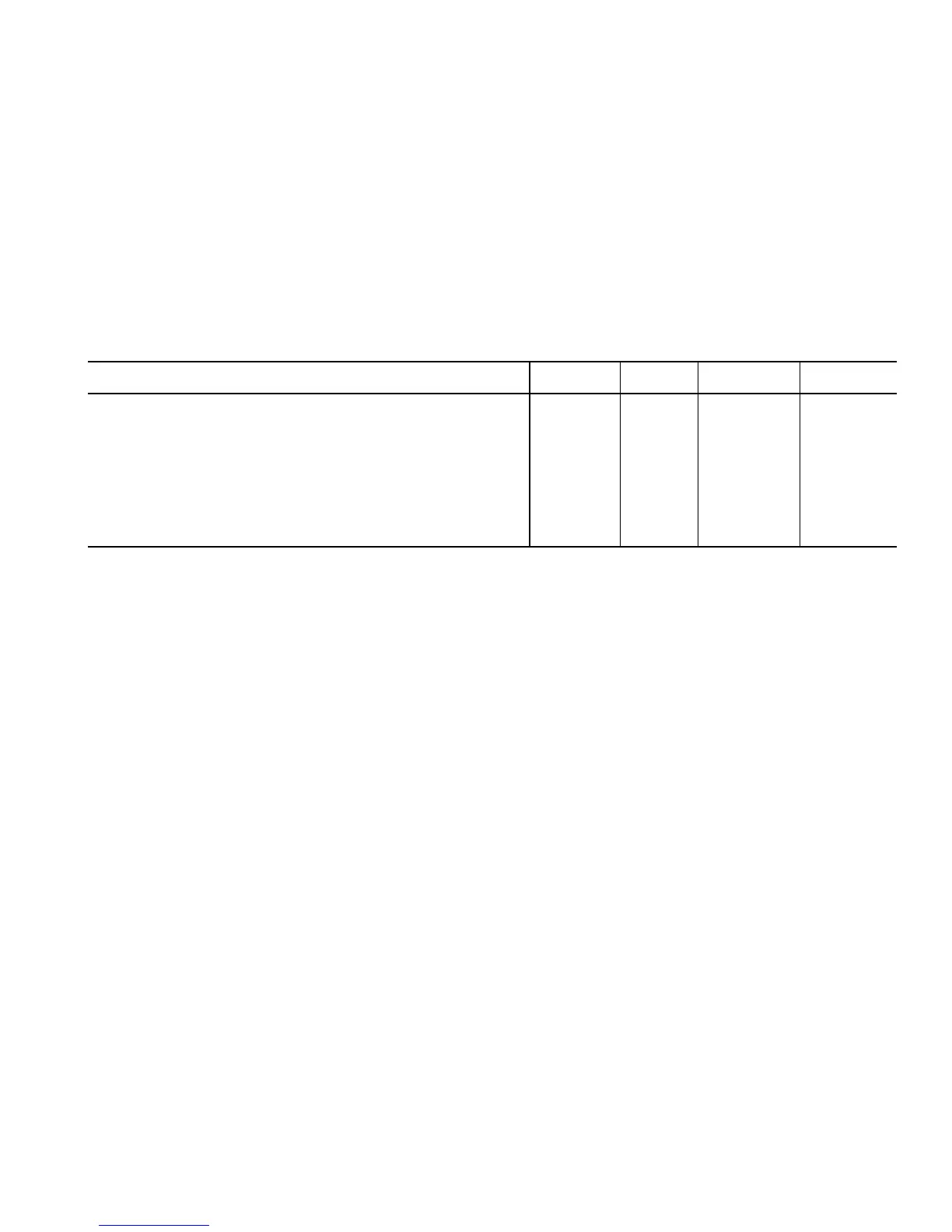

Table 8 —Automatic Stop Safety Devices

CONDITION

CONTROL SAFETY SHUTDOWN SAFETY

SYMBOL RELAY DILUTION INDICATOR

Low chilled water flow (below 50%) 69CW CWX No LD1

Low chilled water temperature (below 36 F [2 C]) 26CW CWX No LD1

Chilled water pump auxiliary contact 88EP CWX No LD1

Cooling water pump auxiliary contact 88CP CWX No LD1

Solution pump motor high temperature 26SP 26MX No LD2

Refrigerant pump motor high temperature 26RP 26MX No LD2

Solution pump motor current overload 51SP 26MX No LD2

Refrigerant pump motor current overload 51RP 26MX No LD2

High-stage generator high pressure (above −.8 in. Hg [−20 mm]) 63GH 63GX Yes LD3

High-stage generator high temperature (above 338 F [170 C]) 26GH 63GX Yes LD3

High absorber pressure (above — 400 mm Hg [−15.8 in. Hg]) ABS ABSX No NONE

PERIODIC SCHEDULED MAINTENANCE

Normal preventive maintenance for 16JT absorption chill-

ers requires periodic, scheduled inspection and service. Each

item in the list below is detailed in the Maintenance Proce-

dures section.

Every Day of Operation

1. Log machine and sytem readings.

2. Exhaust purge.

Every Month of Operation

1. Determine absorber loss.

2. Determine noncondensable accumulation rate.

3. Check capacity control adjustment.

Every 2 Months of Operation

1. Check low-temperature cutout.

2. Check Cycle-Guard™ operation.

Every 6 Months of Operation

1. Check refrigerant charge.

2. Check octyl alcohol.

Every Year of Operation

1. Have solution analyzed.

2. Check tubes for scale and fouling.

Every 3 Years of Operation — Replace service valve

diaphragms.

Every 5 Years or 20,000 Hours of Operation —

(Whichever comes first.)

1. Inspect hermetic pumps.

2. Filter or regenerate the solution if necessary.

MAINTENANCE PROCEDURES

Log Sheets —

Readings of machine and system pressure-

temperature conditions should be recorded daily to aid the

operator in recognizing both normal and abnormal machine

conditions. The record also aids in planning a preventive main-

tenance schedule and in diagnosing machine problems.Atypi-

cal log sheet is shown in Fig. 24.

29

Loading...

Loading...