11

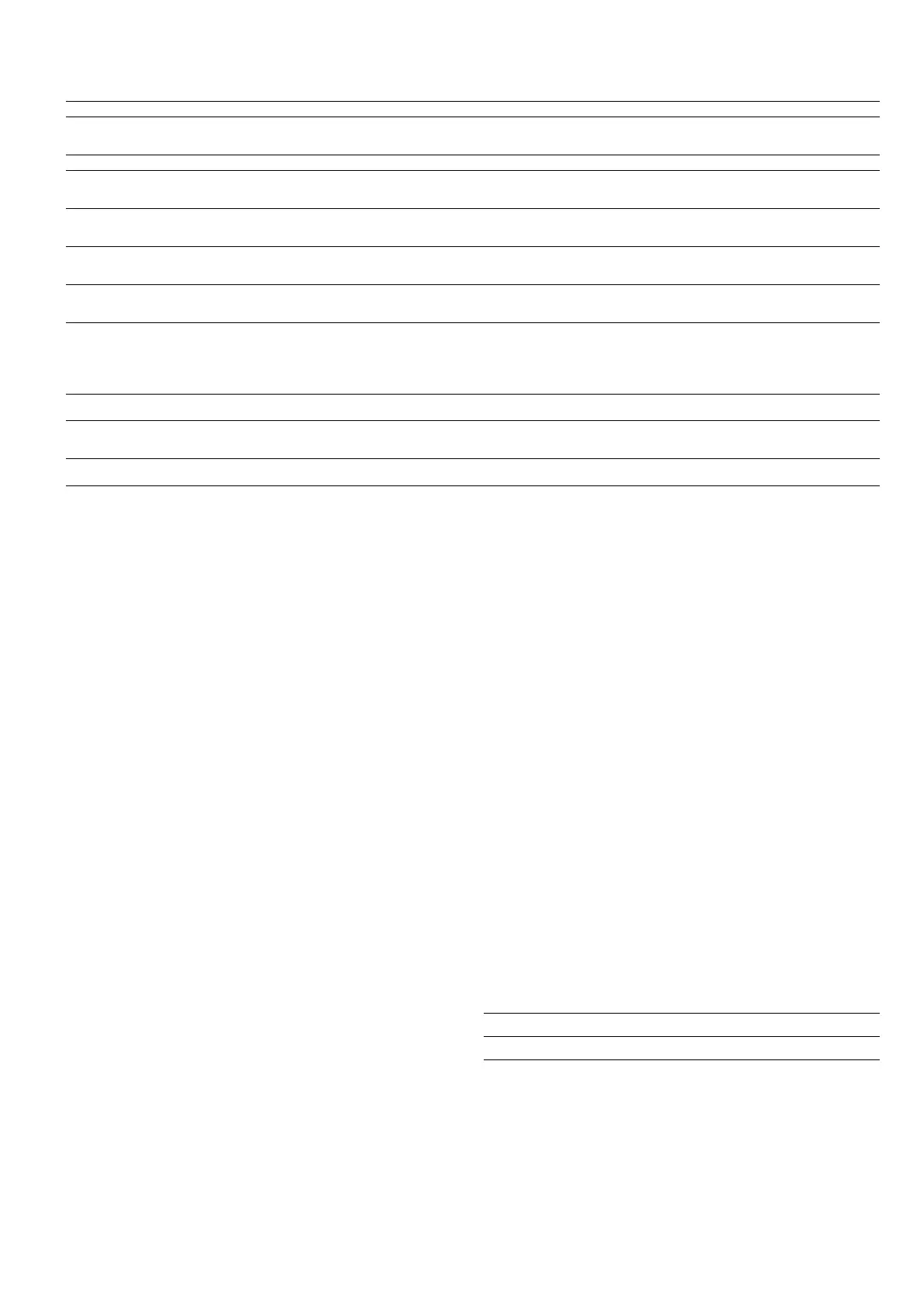

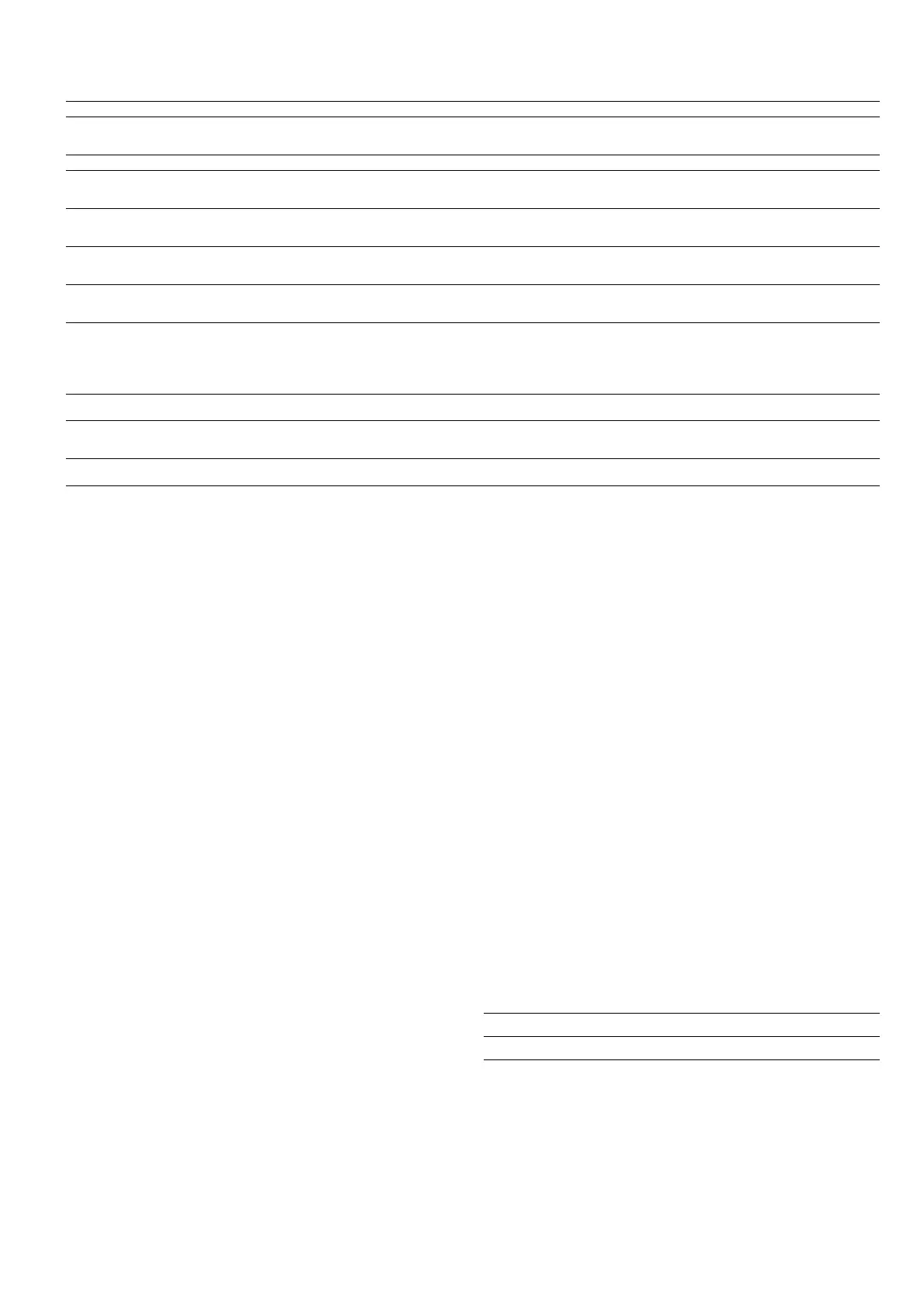

6 - ELECTRICAL DATA FOR UNITS WITH HIGH CONDENSING TEMPERATURES

30HXC 150 and 150A Options

30HXC 080 090 100 110 120 130 140 155 175 190 200 230 260 285 310 345 375

Power circuit

Nominal power supply (Un) V-ph-Hz 400-3-50

Voltage range V 360-440

Control circuit supply The control circuit is supplied via the factory-installed transformer

Max. power input** kW 104 117 131 145 159 174 194 211 230 263 271 310 345 395 422 460 526

Circuit A kW - - - - - -----175195230263211230263

Circuit B kW - - - - - -----96115115132211230263

Max. current drawn (Un - 10%)*** A 190 215 240 265 290 320 355 385 420 480 495 564 630 720 770 840 960

Circuit A A - - - - - -----320355420480385420480

Circuit B A - - - - - -----175210210240385420480

Maximum current drawn (Un)*** A 173 195 218 241 264 291 323 350 382 436 450 514 573 655 700 764 873

Circuit A A - - - - - -----291323382436350382436

Circuit B A - - - - - -----159191191218350382436

Max. starting current, std. unit (Un)**** A 277 312 335 379 402 435 519 546 578 618 1251 1549 1608 1701 1735 1799 1920

Circuit A**** A - - - - - -----1092 1358 1417 1483 1385 1417 1483

Circuit B**** A - - - - - -----9601226 1226 1265 1385 1417 1483

Max. starting current/max. current draw

ratio, unit 1.61 1.60 1.54 1.57 1.52 1.49 1.61 1.56 1.51 1.42 2.78 3.02 2.81 2.60 2.48 2.36 2.20

Max. starting current/max. current draw

ratio, circuit A - - - - - -----3.75 4.21 3.71 3.40 3.96 3.71 3.40

Max. starting current/max. current draw

ratio, circuit B - - - - - ---- 6.03 6.42 6.42 5.80 3.96 3.71 3.40

Max. starting current - reduced current

start (Un)**** A std. std. std. std. std. std. std. std. std. std. N/A N/A N/A N/A N/A N/A N/A

Three-phase short circuit holding current kA 25 25 25 25 25 25 25 25 25 25 N/A N/A N/A N/A N/A N/A N/A

Circuit A kA - - - - - ----.-25252525252525

Circuit B kA - - - - - -----15151515252525

Customer standby capacity, unit or circ. A,

for evaporator water pump connections† kW8 8 81111 111515151515181830303030

** Power input, compressor, at unit operating limits (evaporator water entering/leaving temperature = 15°C/10°C, condenser entering/leaving water temperature = 40°C/45°C) and a nominal

voltage of 400 V (data given on the unit name plate).

*** Maximum unit operating current at maximum unit power input.

**** Maximum instantaneous starting current (maximum operating current of the smallest compressor(s) + locked rotor current or reduced starting current of the largest compressor)

† Current and power inputs not included in the values above

N/A Not available

The 30HXC 080-375 units for high condensing temperatures

are directly derived from the standard models. Their applicat-

ion range is the same as that of the standard units, but permits

operation at condenser leaving water temperatures up to 63°C.

The PRO-DIALOG control offers all the advantages of the

standard units, plus control of the condenser leaving water

temperature.

The main modifications are:

- Use of 30GX compressors

- Modification of electrical components to operate with

compressors for high condensing temperatures.

- Modification of heat exchangers to meet pressure code

requirements (if necessary).

Option 150

These units are designed for traditional applications for water-

cooled units, but for higher condender leaving water

temperatures than 45°C.

Like the standard units they are equipped with condenser

entering and leaving water sensors, installed on the piping.

It is possible to control the machine at the condenser water

outlet, requiring a factory configuration change and the use of

a heating/cooling inlet reversing device.

Option 150A

These units are designed for water-to-water heat pumps.

They are factory configured as heat pumps (heating/cooling

control as a function of the remote reversing device). The

condenser incorporates thermal insulation that is identical to

that of the evaporator.

Technical information

All information is identical to that of the standard 30HXC

units, except for the following paragraphs.

Selection

There are no nominal conditions for this unit type. The

selection is made using the current electronic catalogue.

Dimensions

These are identical to those of the standard 30HXC units. The

only difference is in the diameter of the incoming field wiring

connection, described in the chapter “Recommended selection”.

Refer to the dimensional drawings for these units, before

proceeding with the wiring.

Compressor

See 30GX compressor table.

Options and accessories

All options available for the standard 30HXC units are compa-

tible, except:

Option 5, brine unit Special unit

Option 25, soft start, 30HXC 200-375 units Not available

Attention:

If units have two different operating modes - one with high

condensing temperature and the other with low condensing

temperature - and the transition is made with the unit in

operation, the temperature must not vary by more than 3 K

per minute. In cases where this is not possible, it is recom-

mended to go through a unit start/stop switch (remote start/

stop available for standard units).

Loading...

Loading...