40MBFAQ: Service Manual

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

6

SYSTEM EVACUATION AND CHARGING

Refrigerant tubes and indoor coil should be evacuated using the

recommended deep vacuum method of 500 microns. The alternate triple

evacuation method may be used if the following procedure is followed.

Always break a vacuum with dry nitrogen.

System Vacuum and Charge

Using Vacuum Pump

1. Completely tighten the flare nuts (A, B, C, D, E). Fully open all

circuits service valves. Connect the manifold gage charge hose to the

charge port of the low side Master service valve to evacuate all

circuits at the same time (see Fig. 5).

2. Connect the charge hose to the vacuum pump.

3. Fully open the low side of the manifold gage (see Fig. 6).

4. Start the vacuum pump.

5. Evacuate using the triple evacuation method.

6. After evacuation is complete, fully close the low side of the

manifold gage and stop the vacuum pump operation.

7. The factory charge contained in the outdoor unit is good for up to 25

ft. (8 m) of line length.

8. Disconnect the charge hose from the charge connection of the low

side service valve.

9. Fully open the service valves (B and A).

10. Securely tighten the service valve caps.

A220978

Fig. 5 — Service Valve

A220979

Fig. 6 — Manifold

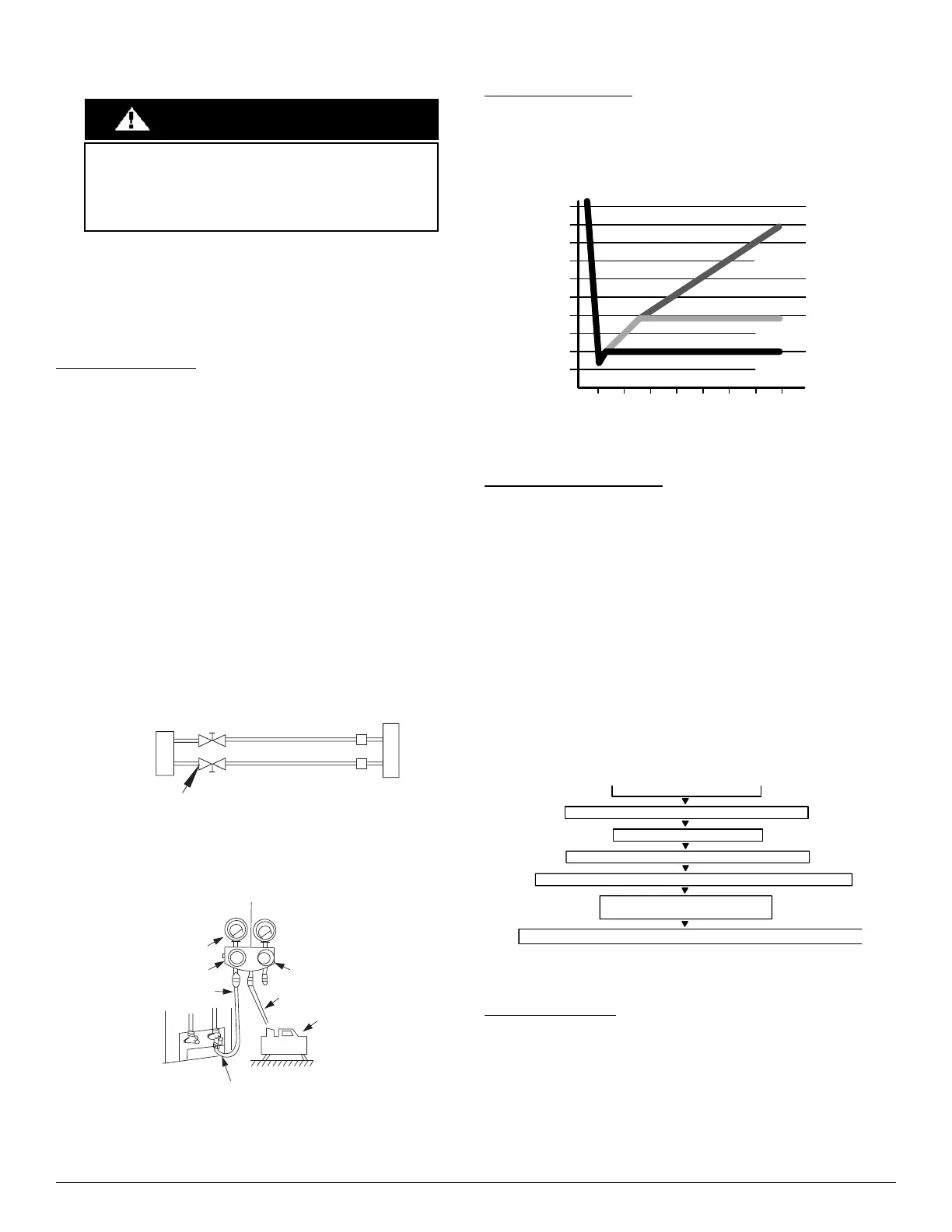

Deep Vacuum Method

The deep vacuum method requires a vacuum pump capable of pulling a

vacuum of 500 microns and a vacuum gage capable of accurately measuring

this vacuum depth. The deep vacuum method is the most positive way of

ensuring a system is free of air and liquid water (see Fig. 7).

A220980

Fig. 7 — Deep Vacuum Method

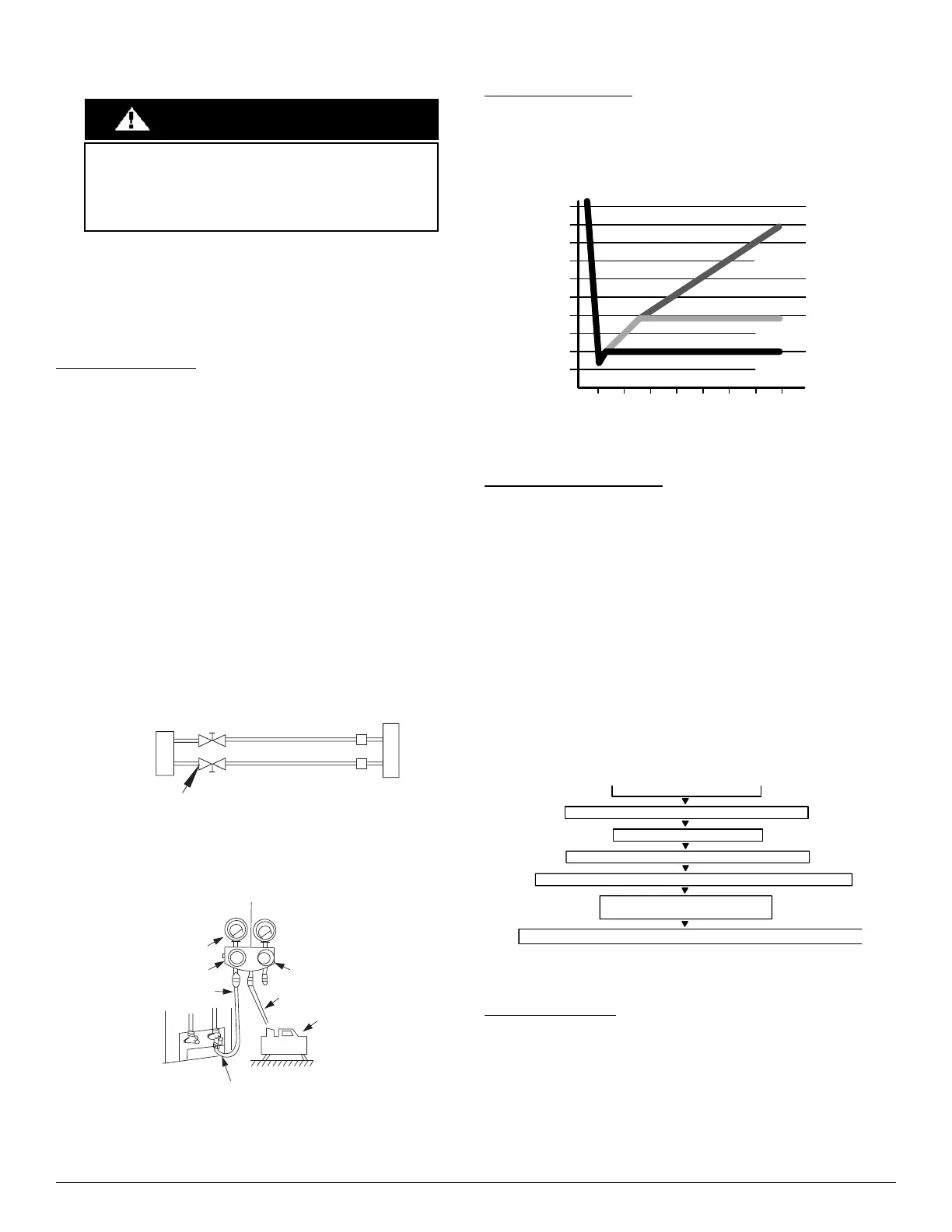

Triple Evacuation Method

The triple evacuation method should be used. Refer to Fig. 8 and proceed

as follows:

1. Pump the system down to 1500 microns and allow the pump to

continue operating for an additional 15 minutes.

2. Close the service valves and shut off the vacuum pump.

3. Connect a dry nitrogen cylinder and regulator to the system and

break vacuum until the system reaches 2 psig.

4. Close the service valve and allow the system to stand for one hour.

During this time, the dry nitrogen can diffuse throughout the system

absorbing moisture.

5. Pump the system down to 1000 microns.

6. Break the vacuum with dry nitrogen (2 psig).

7. Pump the system down to 500 microns.

8. Perform the hold test for 30 minutes.

A220981

Fig. 8 — Triple Evacuation Method

Final Tubing Check

IMPORTANT: Check to be certain factory tubing on both

indoor and outdoor unit has not shifted during shipment.

Ensure tubes are not rubbing against each other or any sheet

metal. Pay close attention to feeder tubes, making sure wire

ties on feeder tubes are secure and tight.

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage or

improper operation.

Never use the system compressor as a vacuum pump.

CAUTION

Refrigerant

Service Valve

Low Side

High Side

A

B

C

D

Manifold Gage

500 microns

Low side valve

High side valve

Charge hose

Charge hose

Vacuum pump

Low side valve

500

MINUTES

01234 567

1000

1500

LEAK IN

SYSTEM

VACUUM TIGHT

TOO WET

TIGHT

DRY SYSTEM

2000

MICRONS

2500

3000

3500

4000

4500

5000

CHECK FOR TIGHT, DRY SYSTEM

(IF IT HOLDS DEEP VACUUM)

EVACUATE TO 1500 MICRONS

EVACUATE TO 500 MICRONS MINIMUM (HOLD FOR 30 MINUTES)

RELEASE CHARGE INTO SYSTEM BY OPENING VALVES COMPLETELY

BREAK VACUUM WITH DRY NITROGEN TO 2 PSIG

EVACUATE TO 1000 MICRONS

BREAK VACUUM WITH DRY NITROGEN TO 2 PSIG

Loading...

Loading...