Loading...

Loading...

Do you have a question about the Carrier 58UVB series and is the answer not in the manual?

Details essential safety measures, PPE, and critical hazards like fire, shock, and CO poisoning.

Specifies requirements for furnace placement, including clearances and approved locations.

Details the process for installing leveling legs if desired for furnace support.

Covers design and sizing of duct systems, supply and return air connections.

Outlines national and local codes for gas piping installation, including pressure testing.

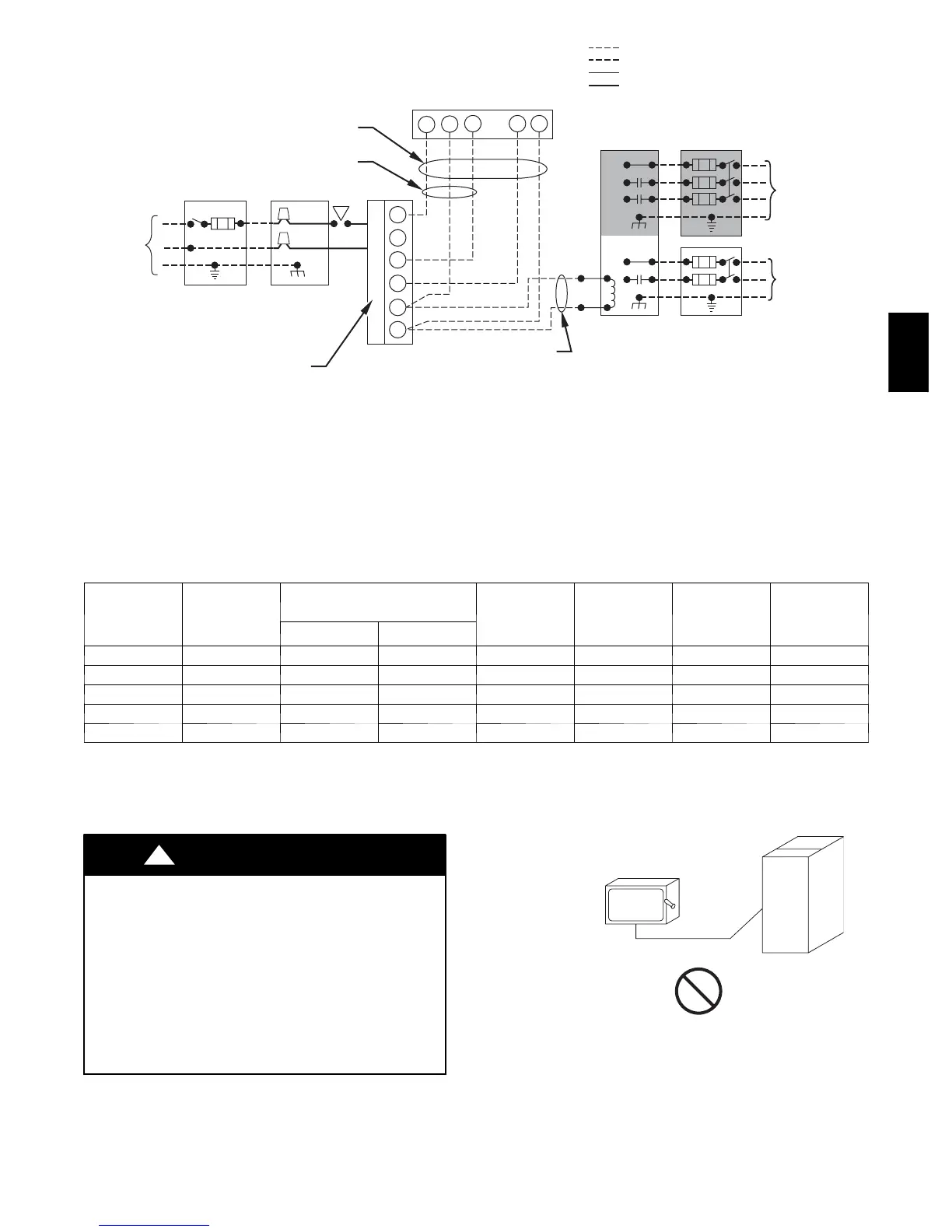

Details electrical connection requirements, voltage compatibility, and wiring diagrams.

Explains direct vent and ventilated combustion air system options and their requirements.

Provides guidelines for sizing, installing, and insulating combustion air and vent pipes.

Specifies required clearances for vent terminals above grade, windows, soffits, and other structures.

Details the installation and protection of the condensate drain system, including trap priming.

Outlines initial checks for power, grounding, thermostat wiring, and blower door installation.

Explains how to configure setup switches for A/C, CF, and other operational modes.

Describes the process of priming the condensate trap to ensure proper draining.

Details how to set gas input rate and manifold pressure according to altitude and gas properties.

Explains how to measure and ensure the air temperature rise is within specified limits.

Covers verification of the primary limit control and pressure switches for safe operation.

Provides a comprehensive checklist to ensure all installation steps are completed correctly.