33

PRE-START-UP

Do not attempt to start the air-conditioning system until the

following checks have been completed.

System Check

1. Check all system components, including the air-handling

equipment. Consult manufacturer's instructions. If the

unit has field-installed accessories, be sure all are proper-

ly installed and wired correctly. Refer to unit wiring

diagrams.

2. Open liquid line and suction line service valves.

3. Check tightness of all electrical connections.

4. Oil should be visible in the compressor sight glasses. An

acceptable oil level in the compressor is from

1

/

8

to

3

/

8

of

sight glass. Adjust the oil level as required. No oil should

be removed unless the crankcase heater has been ener-

gized for at least 24 hours. See Add Oil section on

page 47, for Carrier-approved oils.

5. Electrical power source must agree with unit nameplate.

6. Crankcase heaters must be firmly attached to compres-

sors, and must be on for 24 hours prior to start-up.

7. Fan motors are 3-phase. Check rotation of fans during

first start-up check.

EVACUATION AND DEHYDRATION — Because the

38AP systems use polyolester (POE) oil, which can absorb

moisture, it is important to minimize the amount of time that

the system interior is left exposed to the atmosphere. Minimiz-

ing the exposure time of the oil to the atmosphere will mini-

mize the amount of moisture that needs to be removed during

evacuation.

Once all of the piping connections are complete, leak test

the unit and then pull a deep dehydration vacuum. Connect the

vacuum pump to the charging valve in the suction line and to

the liquid line service valve. For best results, it is recommended

that a vacuum of at least 500 microns (0.5 mm Hg) be ob-

tained. Afterwards, to ensure that no moisture is present in the

system, perform a standing vacuum-rise test.

With the unit in deep vacuum (500 microns or less), isolate

the vacuum pump from the system. Observe the rate-of-rise of

the vacuum in the system. If the vacuum rises by more than

50 microns in a 30-minute time period, then continue the dehy-

dration process. Maintain a vacuum on the system until the

standing vacuum requirement is met. This will ensure a dry

system.

By following these evacuation and dehydration procedures,

the amount of moisture present in the system will be mini-

mized. It is required that liquid line filter driers be installed

between the condenser(s) and the expansion devices to capture

any foreign debris and provide additional moisture removal

capacity.

START-UP

Compressor crankcase heaters must be on for 24 hours be-

fore start-up. To energize the crankcase heaters, close the field

disconnect and turn on the fan circuit breakers. Leave the com-

pressor circuit breakers off/open. The crankcase heaters are

now energized.

Preliminary Charge — Refer to GTAC II (General

Training Air Conditioning), Module 5, Charging, Recovery,

Recycling, and Reclamation for charging procedures. Using

the liquid charging method and charging by weight procedure,

charge each circuit with the amount of Puron

®

refrigerant

(R-410A) listed in Table 15.

IMPORTANT: Before beginning Pre-Start-Up or Start-Up,

review Start-Up Checklist at the back of this publication.

The checklist assures proper start-up of a unit and provides

a record of unit condition, application requirements, system

information, and operation at initial start-up.

IMPORTANT: Before beginning Pre-Start-Up or Start-Up,

review Start-Up Checklist at the back of this publication.

The checklist assures proper start-up of a unit and provides

a record of unit condition, application requirements, system

information, and operation at initial start-up.

CAUTION

Crankcase heaters on all units are wired into the control cir-

cuit, so they are always operable as long as the main power

supply disconnect is on (closed), even if any safety device

is open. Compressor heaters must be on for 24 hours prior

to the start-up of any compressor. Equipment damage

could result if heaters are not energized for at least 24 hours

prior to compressor start-up.

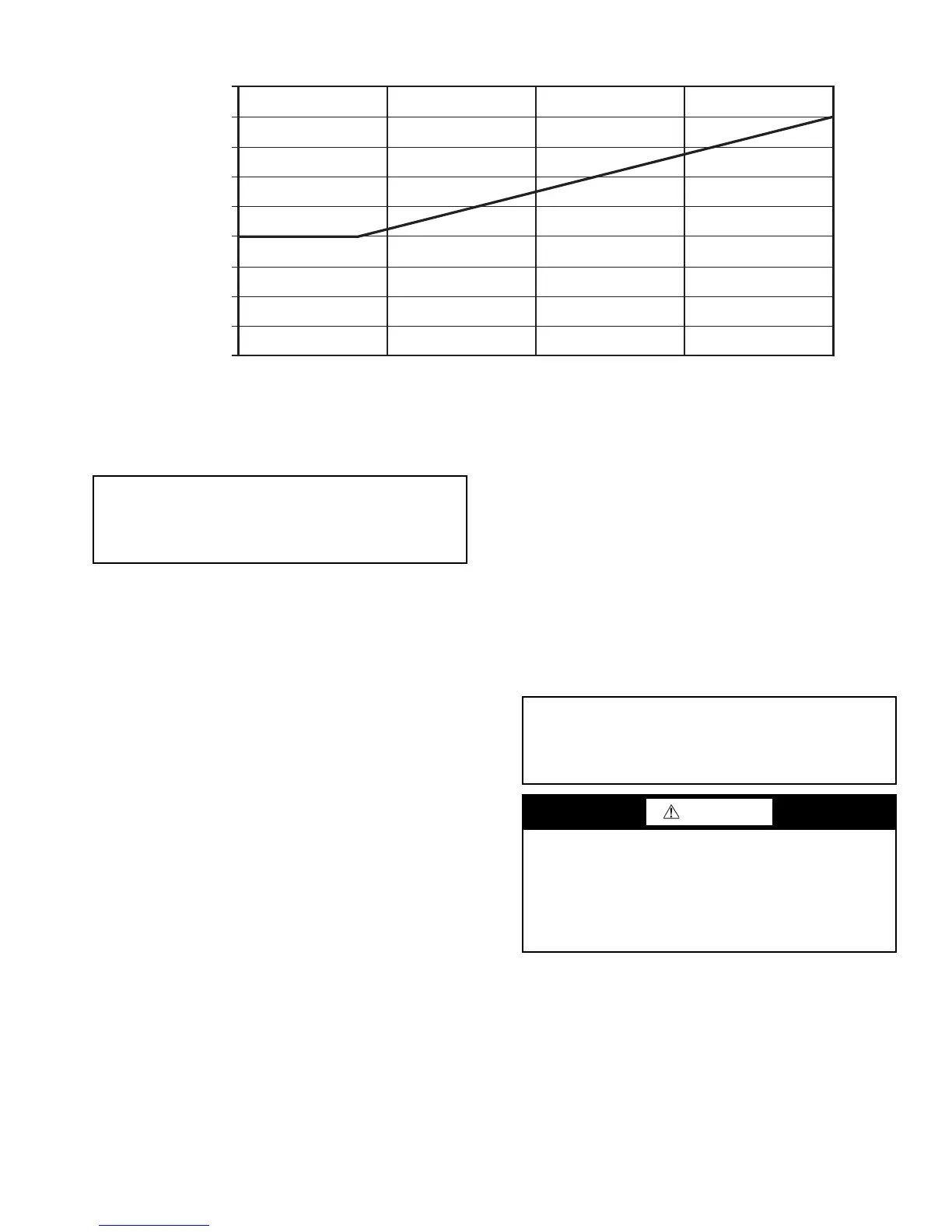

(F)

90

80

70

60

50

40

30

20

10

0

(C)

32.2

26.7

21.1

15.6

10.0

4.4

-1.1

-6.7

-12.2

-17.8

SUPPLY SETPOINT

0 5 10 15 20

SETPOINT SIGNAL – 4-20 mA INPUT

Fig. 34 — 4 to 20 mA Supply Set Point