ROUBLESHOOTING

T

15

208743 Rev. 1

WARNING: Before removing any hoses

or tubes, relieve pressure in the hydraulic

system. With the truck off, open the truck

auxiliary control valve(s) several times in

both directions.

4.4 Sideshift Circuit

There are six potential problems that could affect

sideshifting operation.

• Inadequate upper bearing lubrication or worn bearings.

See sections 5.2-1 and 5.2-2.

• Lower mounting hooks installed incorrectly. See section

5.1 step 6.

• Kinked supply hoses.

• External leaks.

• Incorrect hydraulic pressure/volume from the truck.

• Worn or defective cylinder seals.

1 Check the pressure delivered by the truck. Refer to

the truck service manual. The minimum recommended

truck pressure is 2000 psi (140 bar). TRUCK

PRESSURE MUST NOT EXCEED 3500 PSI (245 BAR),

measured at the carriage hose terminal.

2 Check the flow volume at the carriage hose terminal.

The recommended flow volume is 2 GPM (7.5 L/min).

3 Sideshift completely to the left and hold the control

handle in this position for 5 seconds. Check for external

leaks at the cylinder, fittings and hoses.

4 Sideshift completely to the right and hold the control

handle in this position for 5 seconds. Check for external

leaks at the cylinder, fittings and hoses.

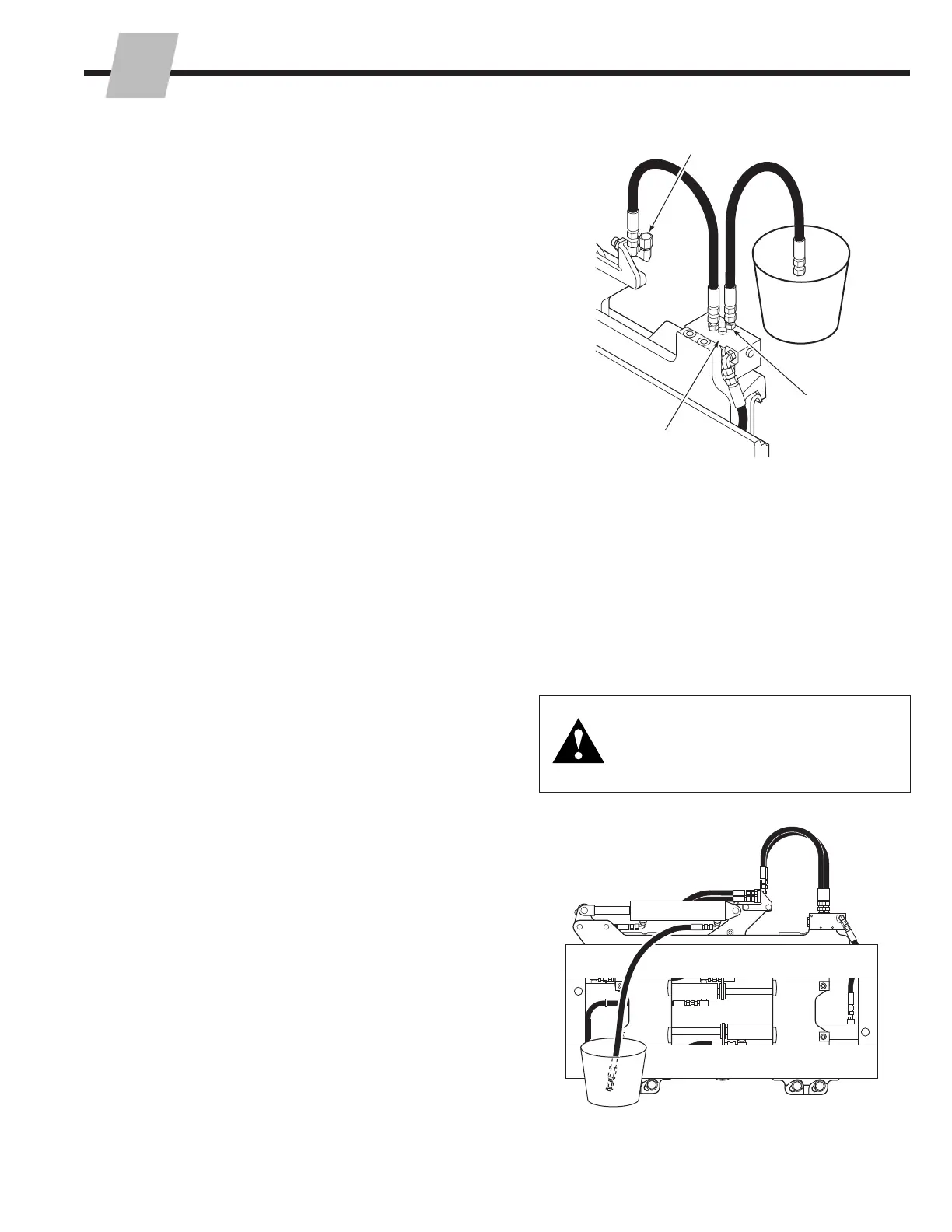

5 Disconnect the LH cylinder hose from the hose terminal

or internal reeving fitting. Cap the supply fitting. Place

the hose end in a bucket. Start the truck. Actuate the

sideshift left control handle for 5 seconds.

• If there is oil flow out of the hose, the cylinder seals

are defective and require service. Refer to Section

5.4-2.

• If there is no oil flow out of the hose, the problem is

not hydraulic.

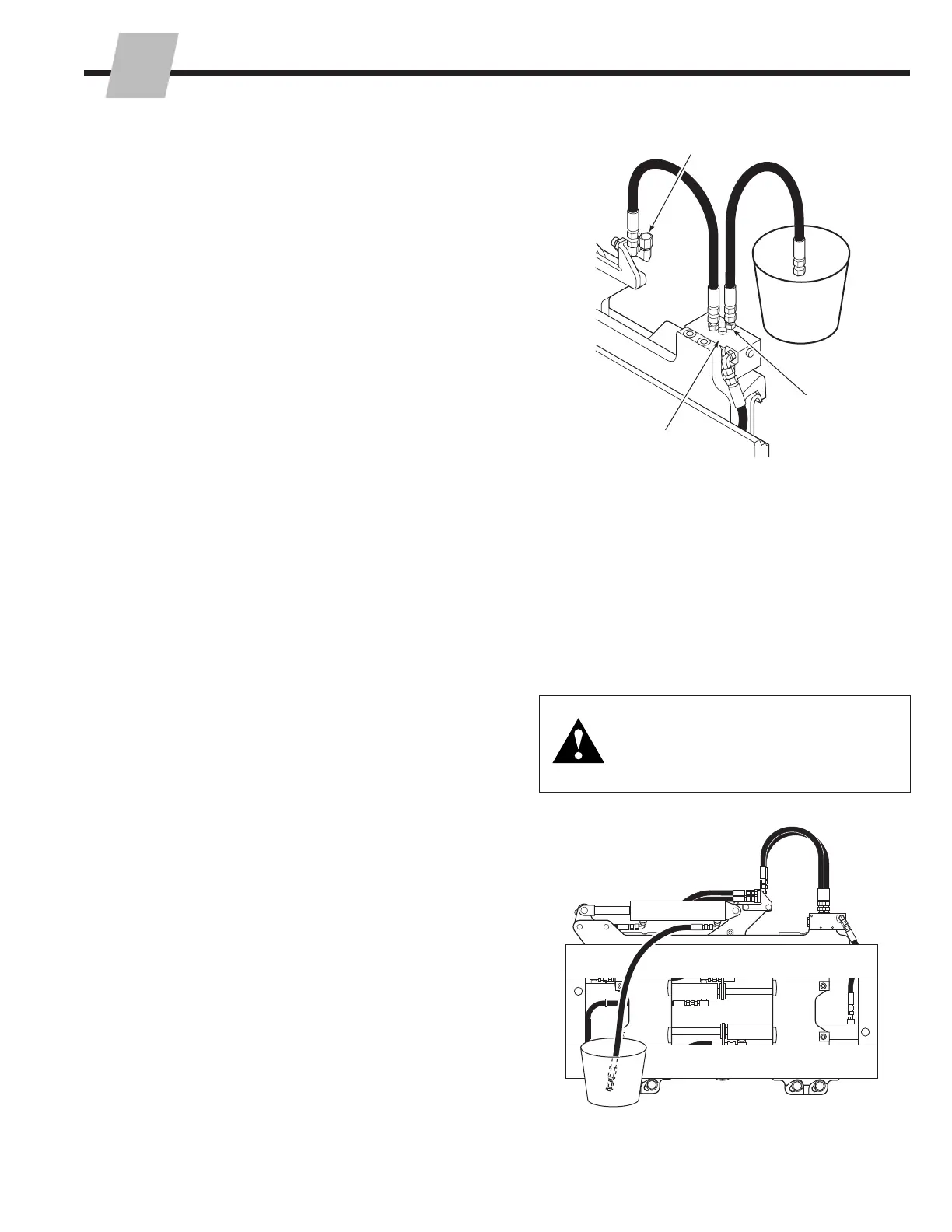

6 Flow Divider Valve equipped attachments – Start

the truck. Position the forks in and out. If the forks do

not position evenly, the flow divider valve cartridge or

cylinders require service. Continue troubleshooting.

7 Position the forks completely outward. Disconnect the

opposite end of the hose connected to the flow divider

valve CL (close) port from its fitting. Cap the fitting

and place the hose end in a bucket. Actuate the truck

handle to position the forks outward.

• If oil flows out of the hose, the cylinder seals require

service. See section 5.5.

• If oil does not flow out of the hose, the flow divider

valve cartridge requires service. See section 5.3-2.

CLOSE

Port

Cap

fitting

Flow Divider

Valve

Loading...

Loading...