F

10. Faults and remedies

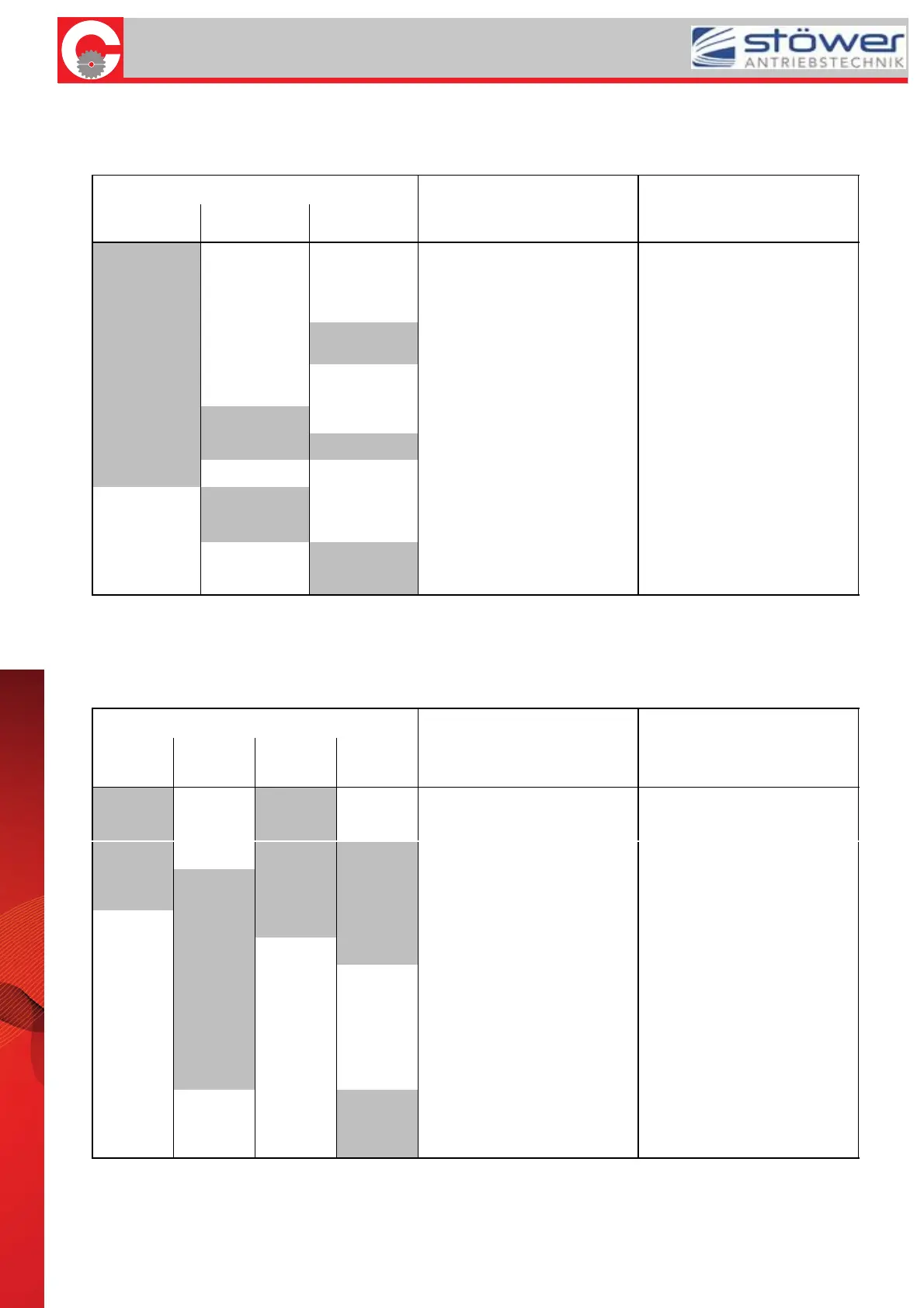

Fault Possible causes Remedy

Bearing is too hot Bearing noise*) Motor runs

unevenly

Too much grease in bearing Remove excess grease

Bearing dirty Replace bearing

Belt tension too high Reduce belt tension

Coupling forces are pulling or

pushing

Realign motor, correct coupling

Coolant temperature above 40°C

(104°F)

Adjust temperature of cooling air

Not enough grease in the bearing Grease according to specifications

Motor incorrectly mounted Check mounting type of motor

Bearing grease dark coloured Check bearing currents

Scoring at bearing inner race, e.g.

caused by motor start with locked

bearing

Replace bearing, avoid vibrations

at standstill

Unbalance caused by coupling Exact balancing

Motor fastening unstable Check fastening

*) If remedies described are insufficient, we recommend to replace the bearings.

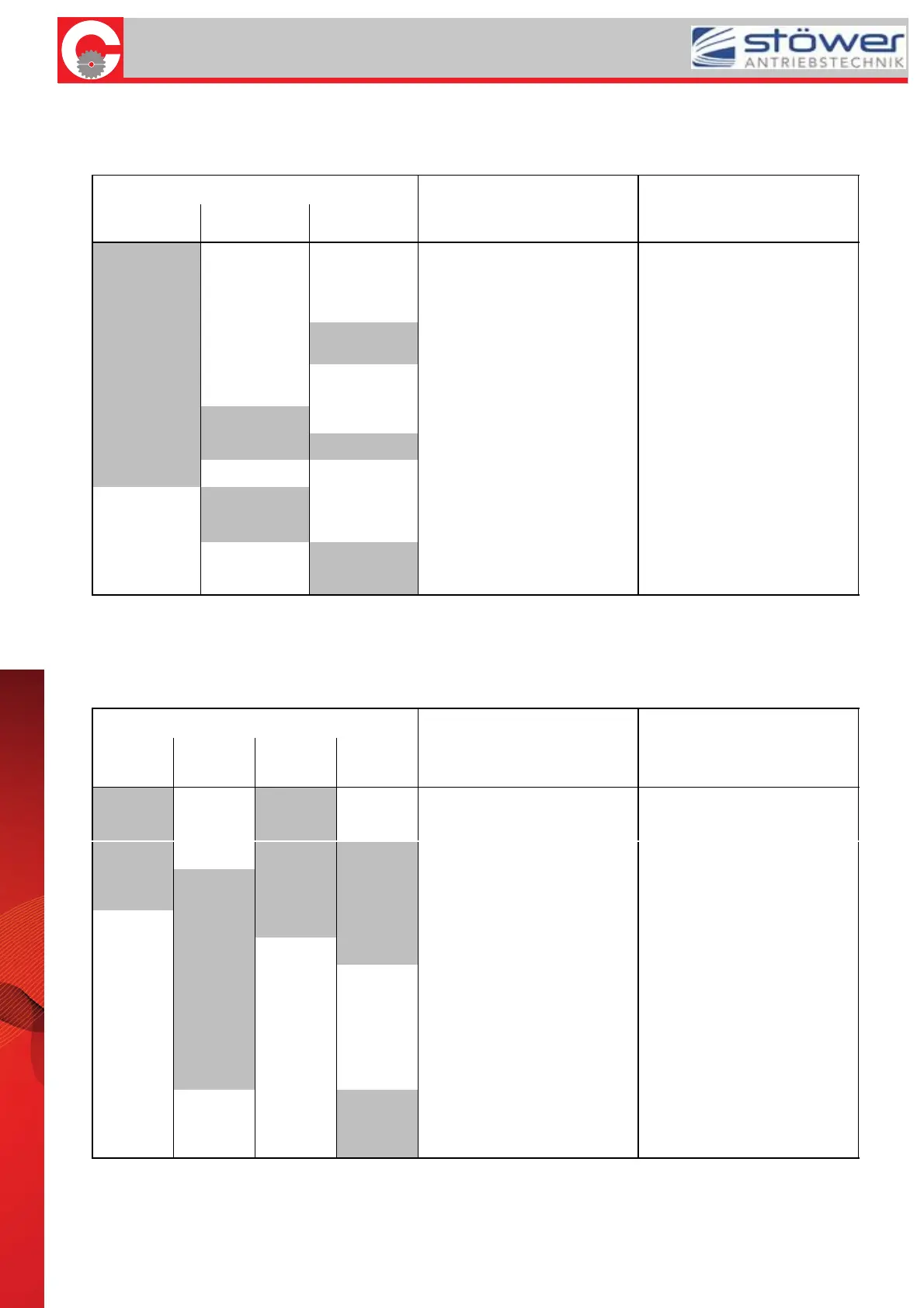

Fault Possible causes Remedy

Motor does

not start

Motor is too

hot

High

decrease in

speed

Protective

device

triggers

Countertorque too high Check motor– and load torque

Mains voltage too low Check mains conditions

Phase interruption Check mains supply

Wrong winding connection

Observe wiring diagram and rating

plate

Overload Compare data on rating plate

Too many starts per hour Observe rated duty type

Insufficient ventilation

Check ventilation passages, check

direction of rotation

Insufficient cooling

Check cooling water inlet and

outlet temperature

Ventilation passages or water

chambers dirty

Clean

Short–circuit of winding or terminal

board

Measure insulation resistance

Starting time exceeded Check starting conditions

Faults and remedies

26

C - SERIE BESTRIEBE- UND wARTUNGSANLEITUNG

26

C - SERIE BESTRIEBE- UND wARTUNGSANLEITUNG

CHM - SERIES Maintenance and Sparepartlist

Stöwer Antriebstechnik GmbH, Enneststrasse 3, 51702 Bergneustadt, Tel. 02261-40970, Fax: 41309, www.stoewer-getriebe.de

Loading...

Loading...