Page 107

Static Pressure

Design

5. Method For Duct Calculation (equal friction method)

1)Draw schematic view of the duct system.

1)Make notes for air volume and mark clearly the elbow, the branch parts, the air discharge outlet.

1)Select one main ducting route (where the maximum static pressure loss occures).

1)Select the air velocity for the main duct in accordance with the desirable air velocity.

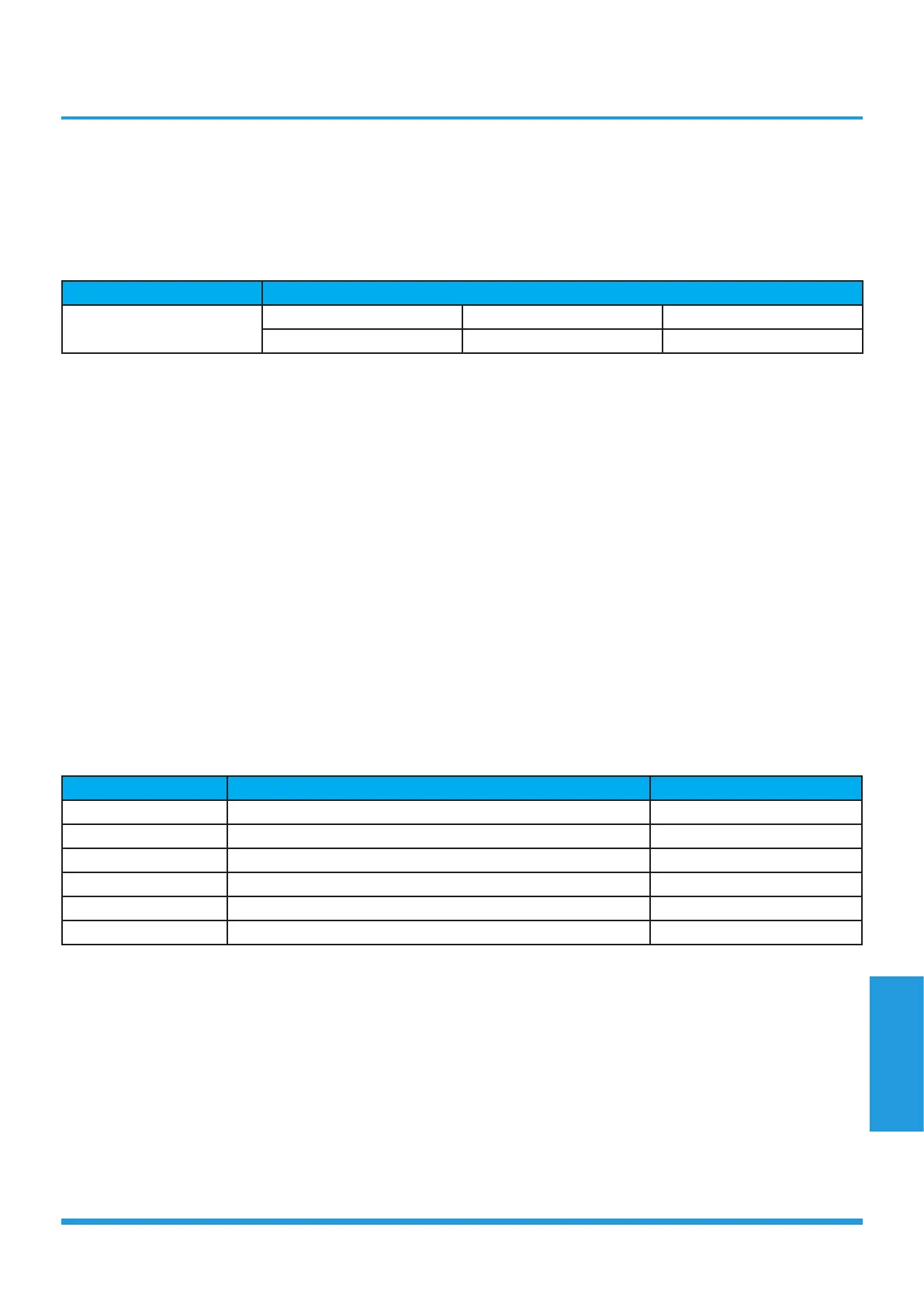

Typical design velocity (m/s)

Main duct

Residence Public building Factory

3.5~6.0 5.0~8.0 6.0~11.0

1)Since the velocity and air volume are fixed for main duct, then use the Friction loss chart to find standard friction loss.

1)Use air volume and friction loss to find corresponding duct size and velocity for each part of main duct through

Fricitions loss chart.

1)Find the dynamic loss of main ducting route according to the velocity. and type of special fittings (elbows, junctions,

regulating flaps, etc.)

1)Obtain the duct size and velocity of each branch duct based on the air volume and the same standard friction loss as

for the main duct.

1)Find the dynamic loss of branch duct.

1)Calculate the total pressure loss.

6. Unit Conversion

• 1 inch water=248.8 N/m

2

(Pa)=0.0361 lb/in

2

(psi)=25.4 kg/cm

2

=0.0739 in mercury

• 1 ft

3

/min (cfm)=1.7 m

3

/h

• 1 ft/min=5.08*10-3 m/s

• 1 inch=2.54 cm=0.0254m=0.08333ft

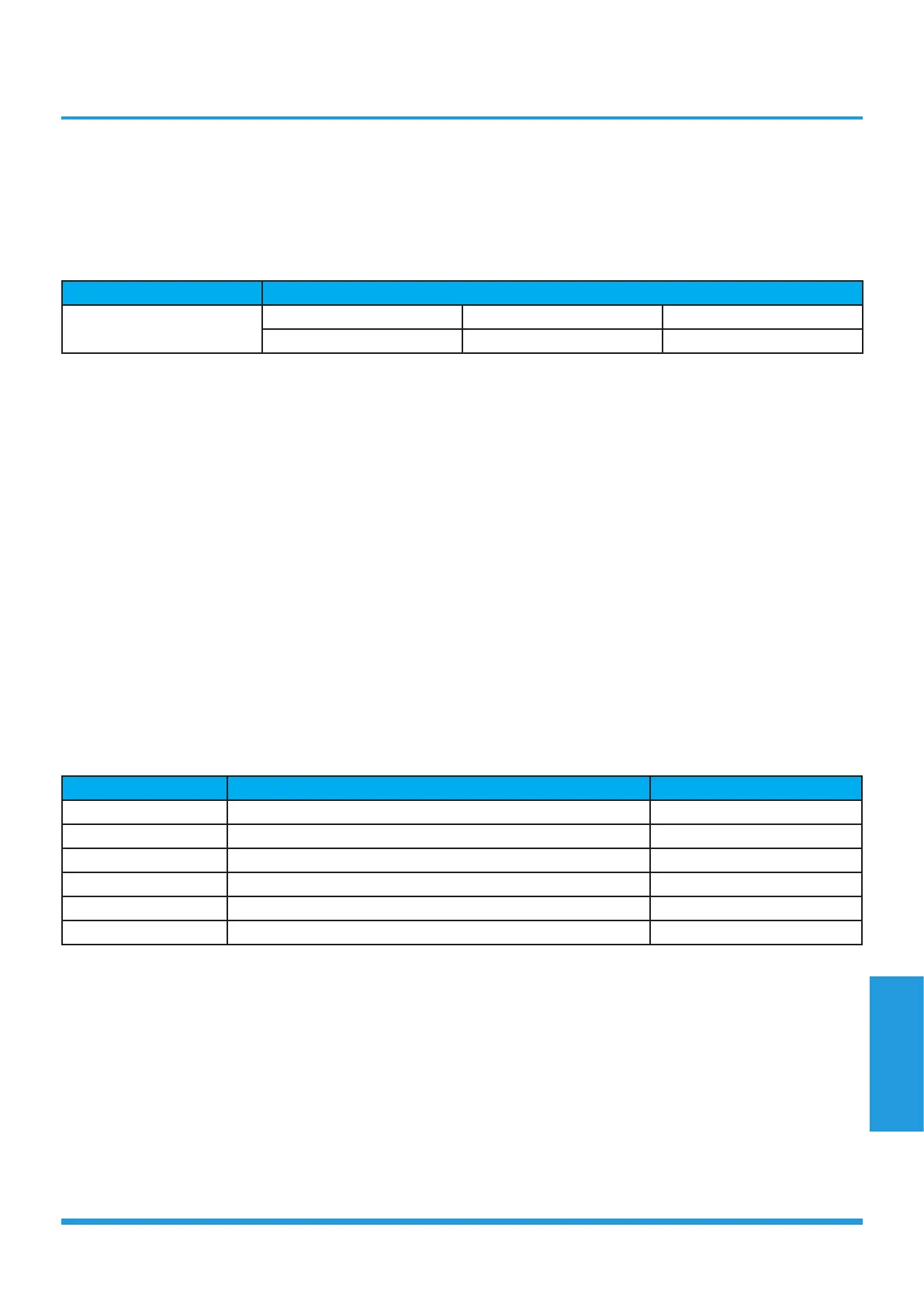

7. Recommended Outlet Velocity For Different Occasion

The permissible sound level and correspondingly maximum air velocity, is determined by the occasion.

Noise / dB(A) Occasion Maximum velocity / m/s

25 Studio, recording room 2

35 Cinema, hospital, library 3

40 Office, school, hotel 4

46 Bank, public hall 5

50 Store, post office 6

70 Factory 10

Loading...

Loading...