assembly

/

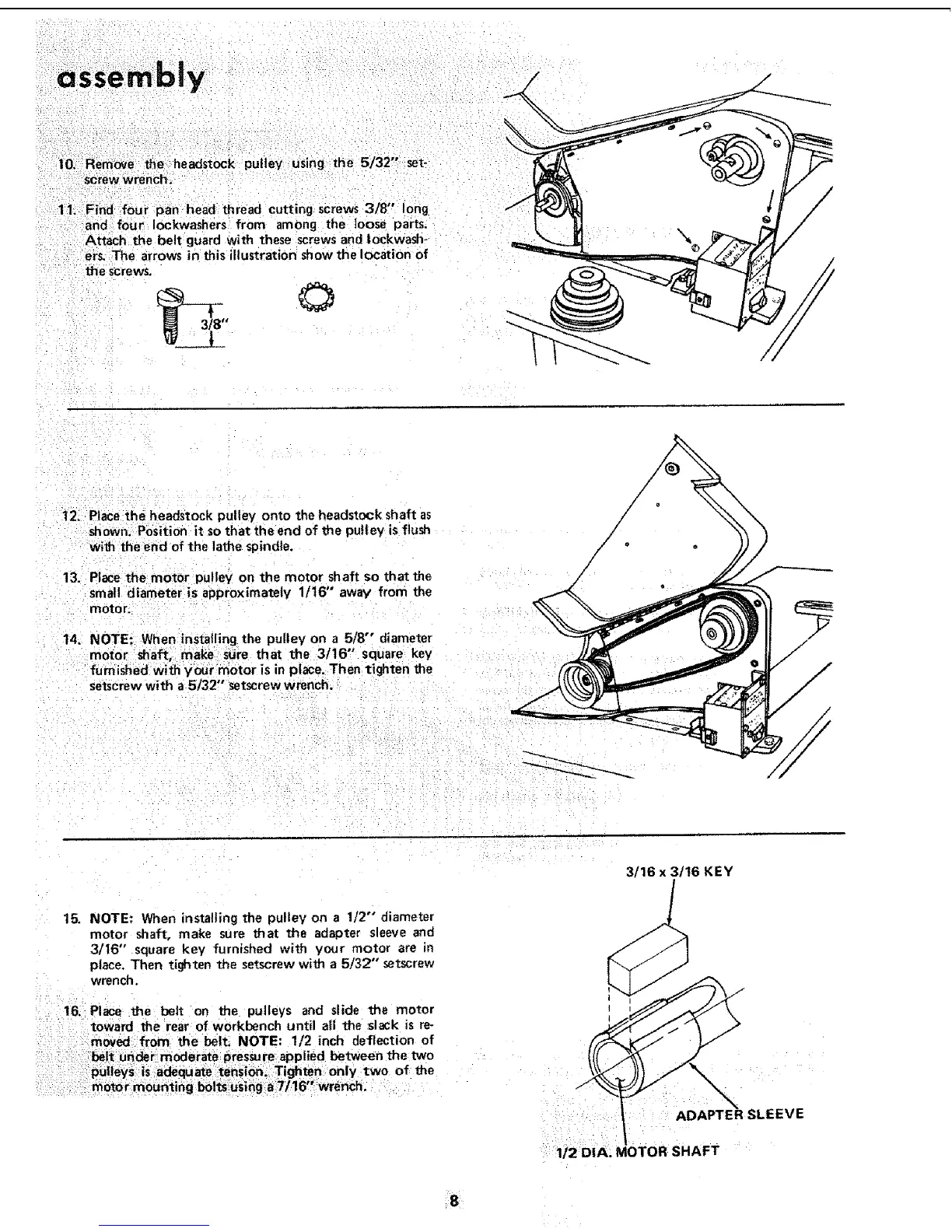

10. Remove the headstock pulley-using the 5/32" set-

screwwrench.

11: Find four pan head thread cutting screws 3/8" long

and four Iockwashers from among the loose parts.

Attach the belt guard with these screwsand Iockwash-

er_ The arrows in this illustration show the location of

the screws.

°i

/

/

12, Place the t_eadstock pulley onto the headstock shaft as

shown. Position it so that the end of the put|ey is flush

with the end of the lathe spindle.

13. Place the motor pulley on the motor shaft so that the

small diameter is approximately 1/16" away from the

motor.

14. NmOoToEr:shWhf_n_1_s_l _tgrteh_hPa_It_/eO_/;65fS"_lud_ra_n_tee;

furnished with your motor is in place. Then tighten the

setscrew with a 5/32" setscrew wrench.

/

/

/

/

/

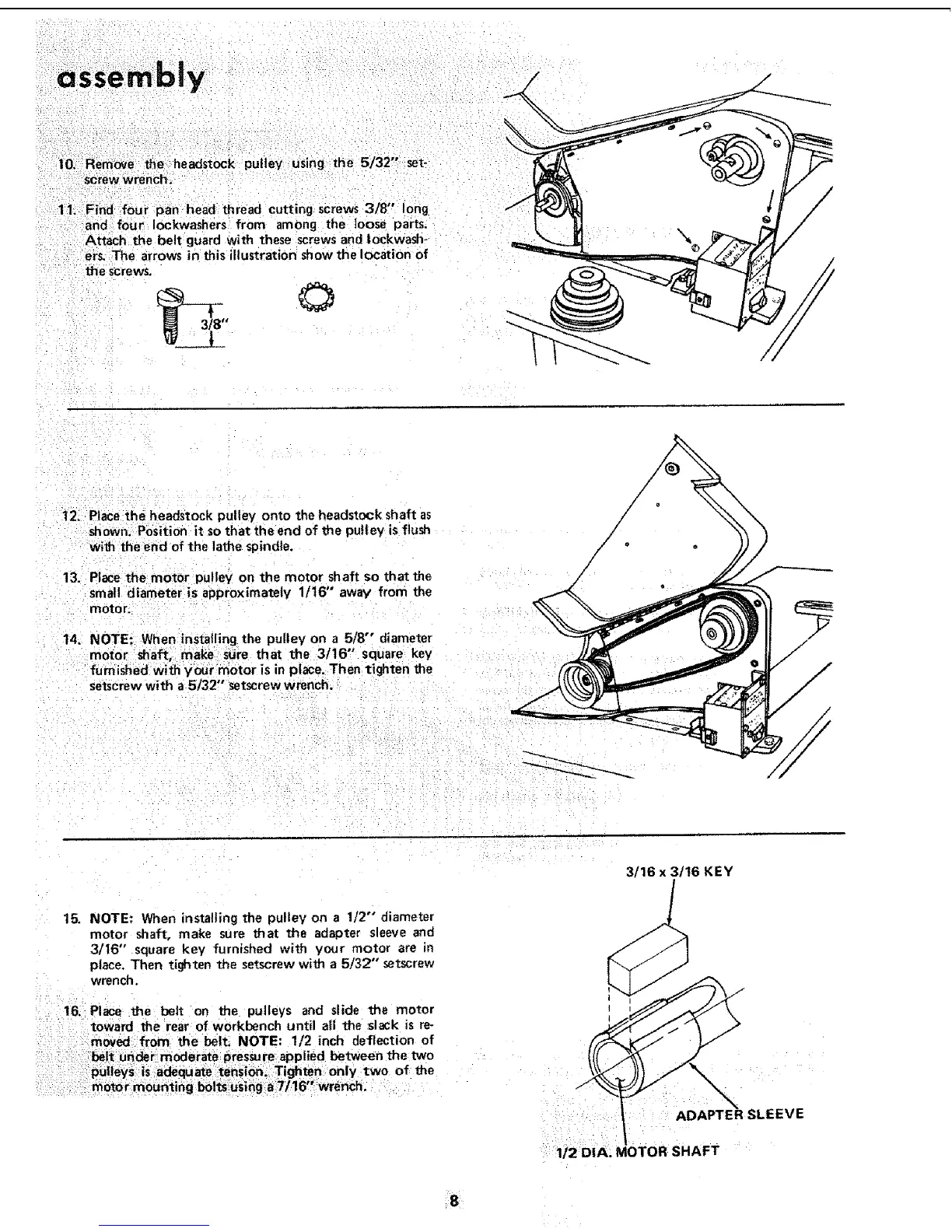

3/16 x 3/16 KEY

15. NOTE: When installing the pulley on a 112" diameter

motor shaft, make sure that the adapter sleeve and

3/I6" square key furnished with your motor are in

place. Then tighten the setscrew with a 5/32" setscrew

wrench,

16, Place the belt on the pulleys and slide the motor

toward the rear of workbench until al_lthe slack is re*

moved from the belt. NOTE: 1/2 inch deflection of

belt under moderate pressure,applied between the two

pulleys is adequate :tenSion, Tighten only two of the

motor mounting boltsusing a7/16 wrench.

ADAPTER SLEEVE

T

1/2 DIA. MOTOR SHAF

Loading...

Loading...