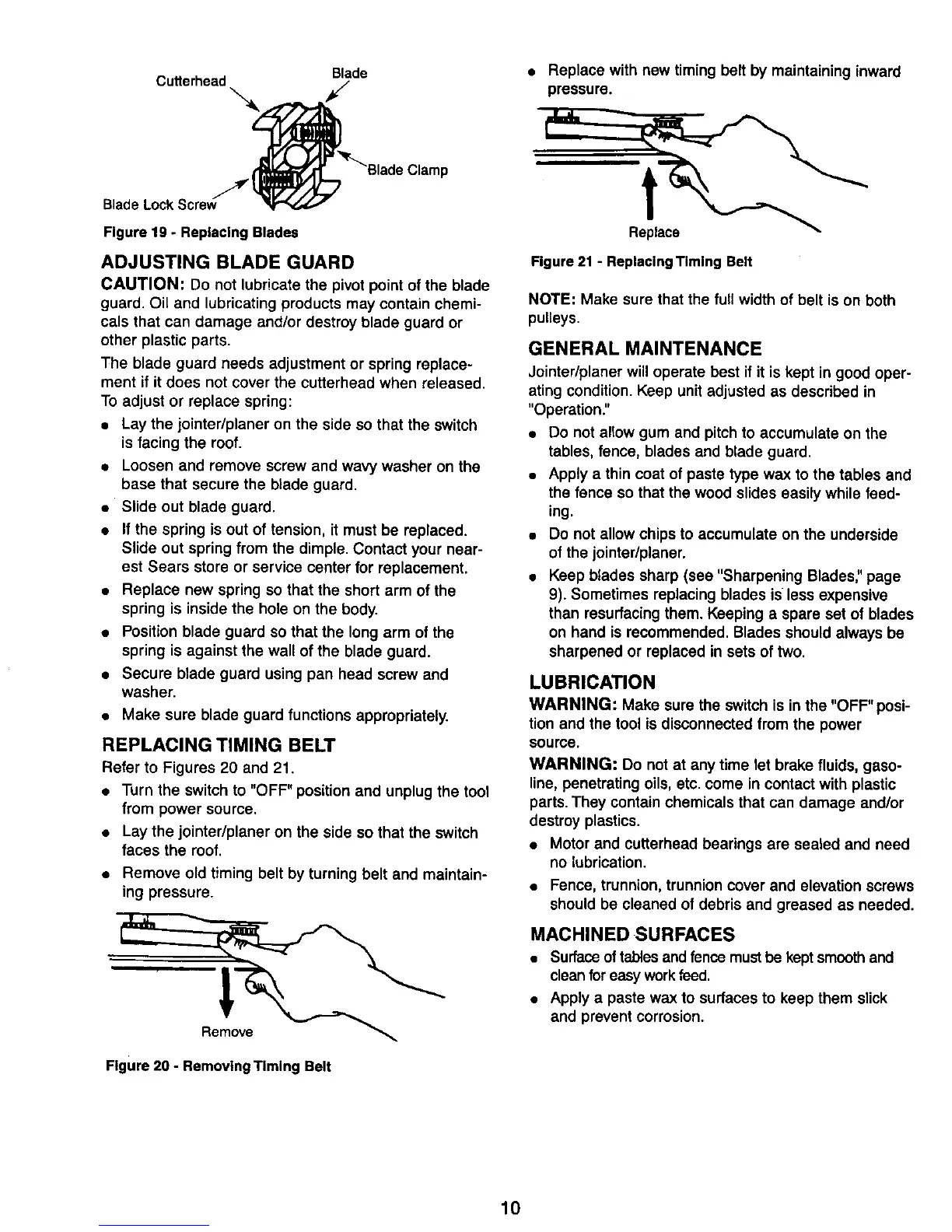

Blade

Cutterhead

Blade Lock Screw

Figure 19 - Replacing Blades

ADJUSTING BLADE GUARD

CAUTION: Do not lubricate the pivot point of the blade

guard. Oil and lubricating products may contain chemi-

cals that can damage and/or destroy blade guard or

other plastic parts.

The blade guard needs adjustment or spring replace-

ment if it does not cover the cutterhead when released.

To adjust or replace spring:

• Lay the jointer/planer on the side so that the switch

is facing the roof.

• Loosen and remove screw and wavy washer on the

base that secure the blade guard.

• Slide out blade guard.

• If the spring is out of tension, it must be replaced.

Slide out spring from the dimple. Contact your near-

est Sears store or service center for replacement.

• Replace new spring so that the short arm of the

spring is inside the hole on the body.

• Position blade guard so that the long arm of the

spring is against the wall of the blade guard.

• Secure blade guard using pan head screw and

washer.

• Make sure blade guard functions appropriately.

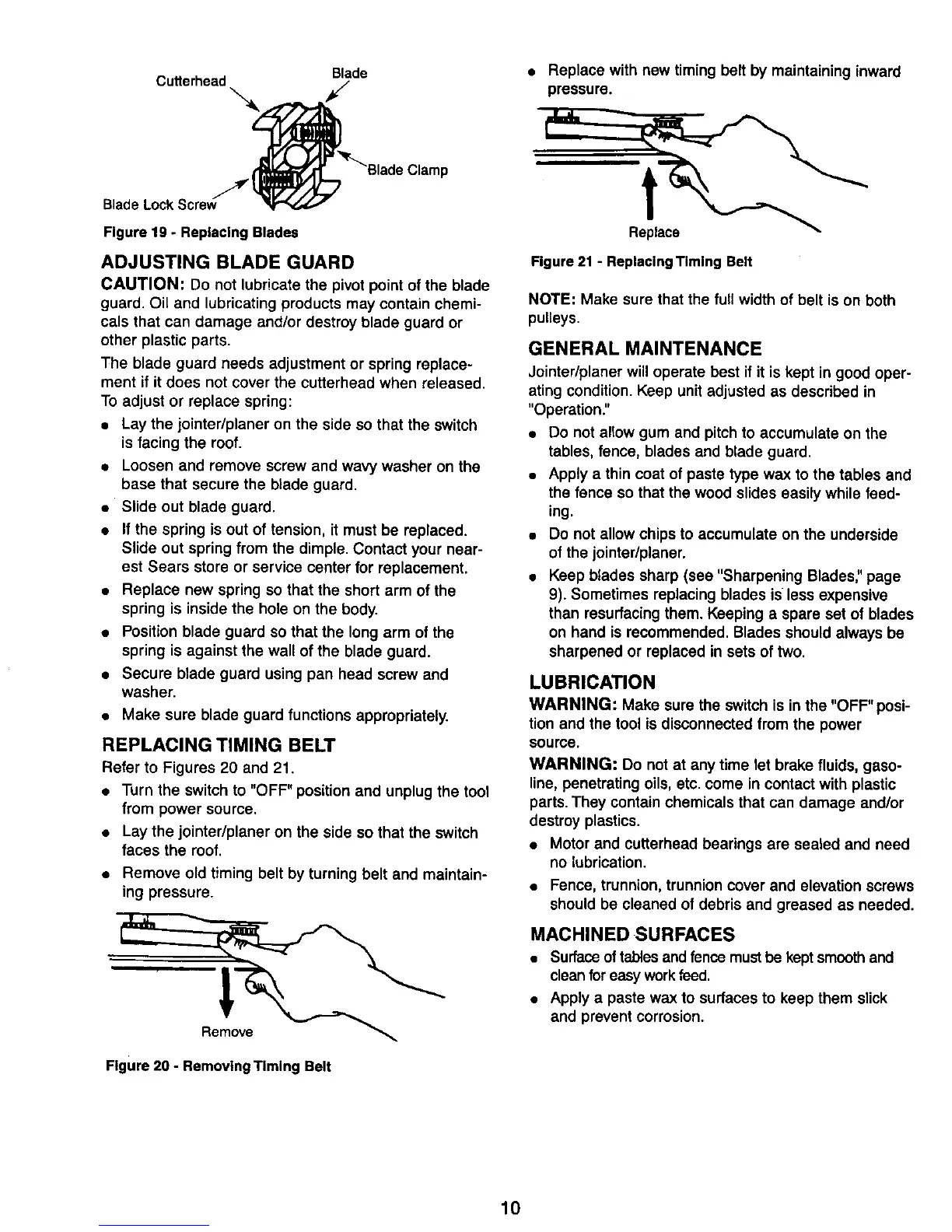

REPLACING TIMING BELT

Refer to Figures 20 and 21.

• Turn the switch to "OFF" position and unplug the tool

from power source.

• Lay the jointer/planer on the side so that the switch

faces the roof.

• Remove old timing belt by turning belt and maintain-

ing pressure.

__ I

' " Re

Figure 20 - Removing Timing Belt

• Replace with new timing belt by maintaining inward

pressure.

Replace "_

Figure 21 - Replacing Timing Belt

NOTE: Make sure that the full width of belt is on both

pulleys.

GENERAL MAINTENANCE

Jointer/planer will operate best if it is kept in good oper-

ating condition. Keep unit adjusted as described in

"Operation."

• Do not allow gum and pitch to accumulate on the

tables, fence, blades and blade guard.

• Apply a thin coat of paste type wax to the tables and

the fence so that the wood slides easily while feed-

ing.

• Do not allow chips to accumulate on the underside

of the jointer/planer.

• Keep blades sharp (see "Sharpening Blades;' page

9). Sometimes replacing blades is less expensive

than resurfacing them. Keeping a spare set of blades

on hand is recommended. Blades should always be

sharpened or replaced in sets of two.

LUBRICATION

WARNING: Make sure the switch is in the "OFF" posi-

tion and the tool is disconnected from the power

source.

WARNING: Do not at any time let brake fluids, gaso-

line, penetrating oils, etc. come in contact with plastic

parts. They contain chemicals that can damage and/or

destroy plastics.

• Motor and cutterhead bearings are sealed and need

no lubrication.

• Fence, trunnion, trunnion cover and elevation screws

should be cleaned of debris and greased as needed.

MACHINED SURFACES

• Surface oftablesand fence must be keptsmoothand

clean for easy workfeed.

• Apply a paste wax to surfaces to keep them slick

and prevent corrosion.

10

Loading...

Loading...