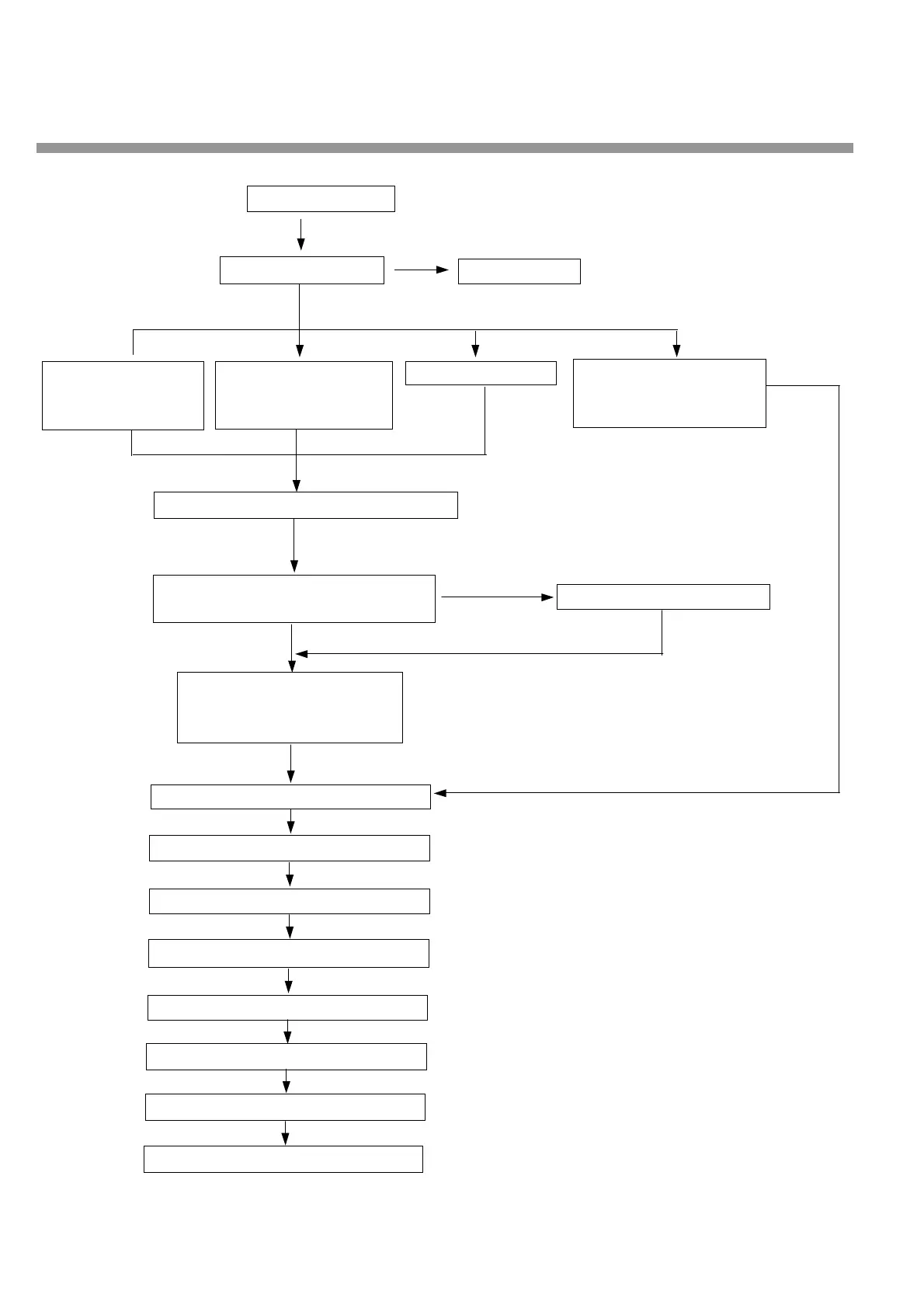

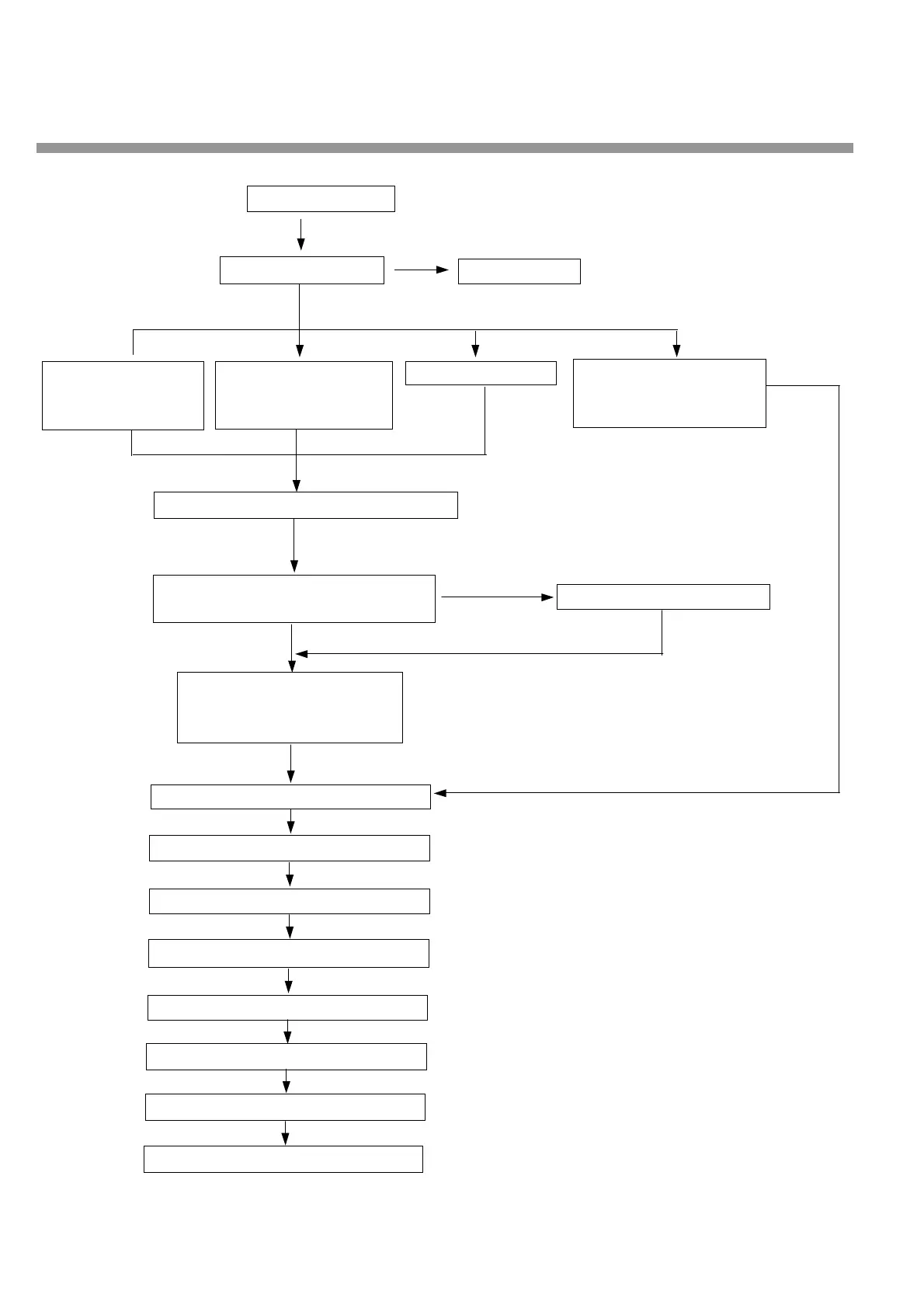

7. CYCLE REFARE FLOW CHART

NO

YES

. Drain compressor oil and

compare with the standad.

. When cutting the dryer, is gelled

oil attached near?

And check if there is now

clogging at the end of capillary.

. No gelled oil below '4'.. Gelled oil up to '5' is generated.

. Make sure to perform concentrated

Nitrogen blow welding.

Service Call

Cycle problem?

Usual repair

Gas leak(High/low

pressure sides)

Bad compressor

(Bad stroke,ejecting)

Cycle clogging

Bad vacuum degree.

Lack of refrigerant,etc.

Judge by oil color of compressor

Comparing with ASTM standard

color check for gelled oil.

Replace cabinet.

Replace compressor.

(Bad compressor)

(Leak in low pressure side)

Replace dryer.

Check degrel of vacuum.

Charge refrigerant.

Air-tight the refrigerant

Check of leak in air-tight portion.

Anticorrosive paint treatment.

Cooling test.

Finish.

17

Loading...

Loading...