5 Piping installation

Installation manual

9

4MWXM-A9

R32 Split series

3P600450-7T – 2022.09

5.1.2 Refrigerant piping insulation

▪ Use polyethylene foam as insulation material:

▪ with a heat transfer rate between 0.041 and 0.052W/mK (0.035

and 0.045kcal/mh°C)

▪ with a heat resistance of at least 120°C

▪ Insulation thickness

Pipe outer diameter

(Ø

p

)

Insulation inner

diameter (Ø

i

)

Insulation thickness

(t)

6.4mm (1/4") 8~10mm ≥10mm

9.5mm (3/8") 12~15mm ≥13mm

12.7mm (1/2") 14~16mm ≥13mm

If the temperature is higher than 30°C and the humidity is higher

than RH80%, the thickness of the insulation materials should be at

least 20 mm to prevent condensation on the surface of the

insulation.

Use separate thermal insulation pipes for the gas and liquid

refrigerant piping.

5.1.3 Refrigerant piping length and height

difference

The shorter the refrigerant piping, the better the performance of the

system.

The piping length and height differences must comply with the

following requirements.

Shortest allowable length per room is 3m.

Refrigerant piping length to each

indoor unit

Refrigerant piping total

length

≤25m ≤50m

Height difference

outdoor-indoor

Height difference

indoor-indoor

Outdoor unit installed

higher than indoor

unit

≤15m ≤7.5m

Outdoor unit installed

lower than at least 1

indoor unit

≤7.5m ≤15m

5.2 Connecting the refrigerant piping

DANGER: RISK OF BURNING/SCALDING

CAUTION

▪ No brazing or welding on site for units with R32

refrigerant charge during shipment.

▪ During installation of the refrigeration system, joining of

parts with at least one part charged shall be performed

taking into account the following requirements: inside

occupied spaces non-permanent joints are NOT

allowed for R32 refrigerant except for site made joints

directly connecting the indoor unit to piping. Site made

joints directly connecting piping to indoor units shall be

of non-permanent type.

CAUTION

Do NOT connect the embedded branch piping and the

outdoor unit when only carrying out piping work without

connecting the indoor unit in order to add another indoor

unit later.

5.2.1 Connections between outdoor and indoor

unit using reducers

Total indoor air conditioning units capacity class that can be

connected to this outdoor unit

≤9.0kW

Port Dimensions Class Reducer

A Liquid Ø6.4mm

Gas Ø9.5mm

15, 20, 25, 35, (42)

(a)

—

B+C Liquid Ø6.4mm

Gas Ø12.7mm

15, 20, 25, 35, (42)

(a)

1+2

(accessory)

42, 50, 60 —

71

(b)

ASYCPIR

To tank Liquid Ø6.4mm

Gas Ø9.5mm

90, 120 —

(a)

Only in case of connection with FTXM42R.

(b)

Only for connection with FBA71A9. Use option ASYCPIR for

liquid (Ø9.5mm→Ø6.4mm) and gas (Ø15.9mm→Ø12.7mm)

piping.

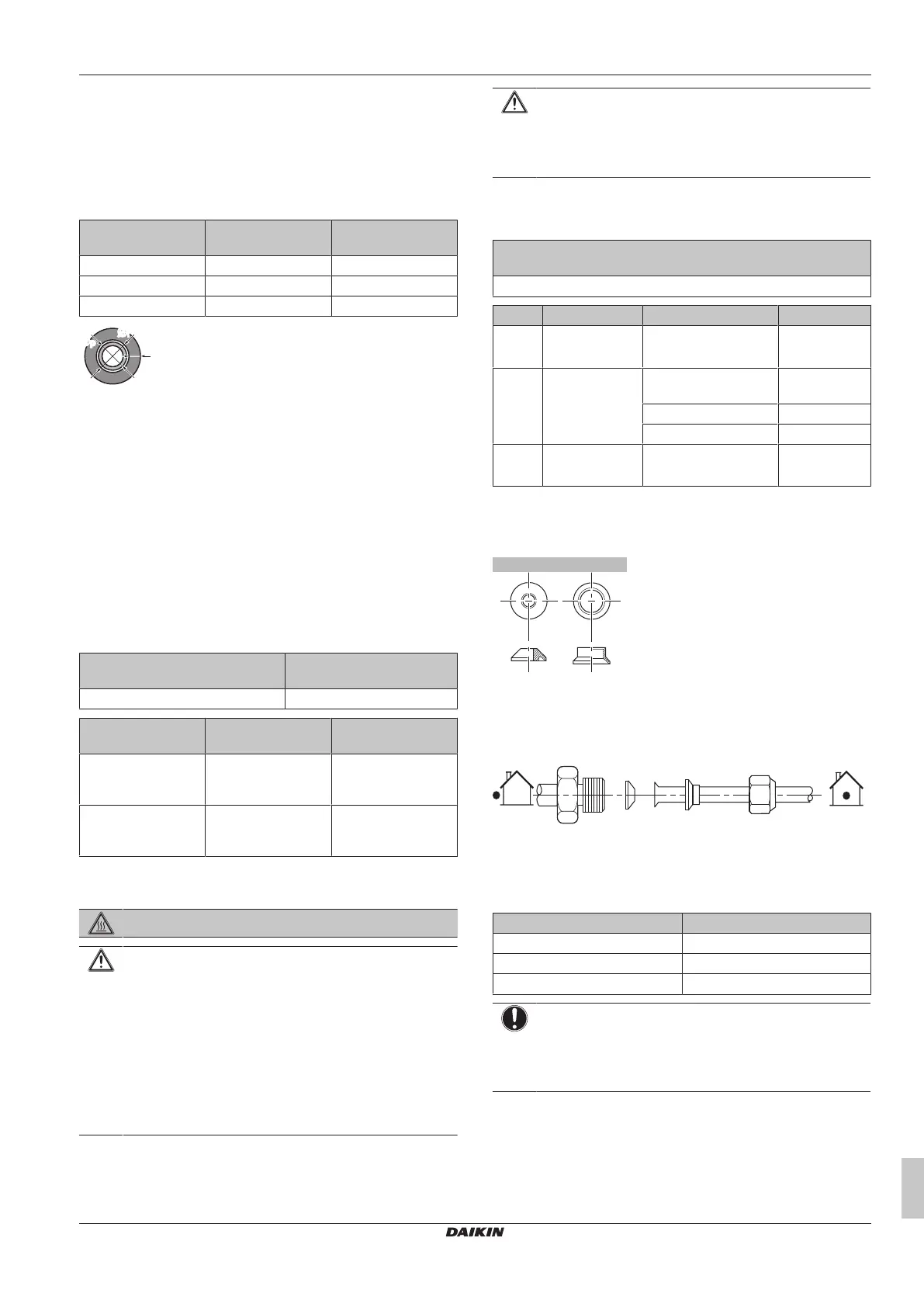

Connection examples:

▪ Connecting a Ø9.5 mm inter unit pipe to a Ø12.7 mm gas pipe

connection port on the outdoor unit

a Reducer 1

b Reducer 2

c Flare nut (on the outdoor unit)

Coat the threaded connection port of the outdoor unit where the flare

nut comes in with refrigeration oil.

Flare nut for (mm) Tightening torque (N•m)

Ø6.4 15~17

Ø9.5 33~39

Ø12.7 50~60

NOTICE

Use an appropriate wrench to avoid damaging the

connection thread by overtightening the flare nut. Be

careful NOT to overtighten the nut, or the smaller pipe may

be damaged (about 2/3-1× the normal torque).

5.2.2 To connect the refrigerant piping to the

outdoor unit

▪ Piping length. Keep field piping as short as possible.

▪ Piping protection. Protect the field piping against physical

damage.

Loading...

Loading...