7 | Piping installation

Installer reference guide

44

2MXM-A, 3MXM-A, 4MXM-A, 5MXM-A

R32 Split series

4P600463-5E – 2021.12

1 Charge the system with nitrogen gas up to a gauge pressure of at least

200kPa (2bar). It is recommended to pressurize to 3000kPa (30bar) in order

to detect small leaks.

2 Check for leaks by applying the bubble test solution to all connections.

3 Discharge all nitrogen gas.

7.3.4 To perform vacuum drying

DANGER: RISK OF EXPLOSION

Do NOT start the unit if it is vacuumed.

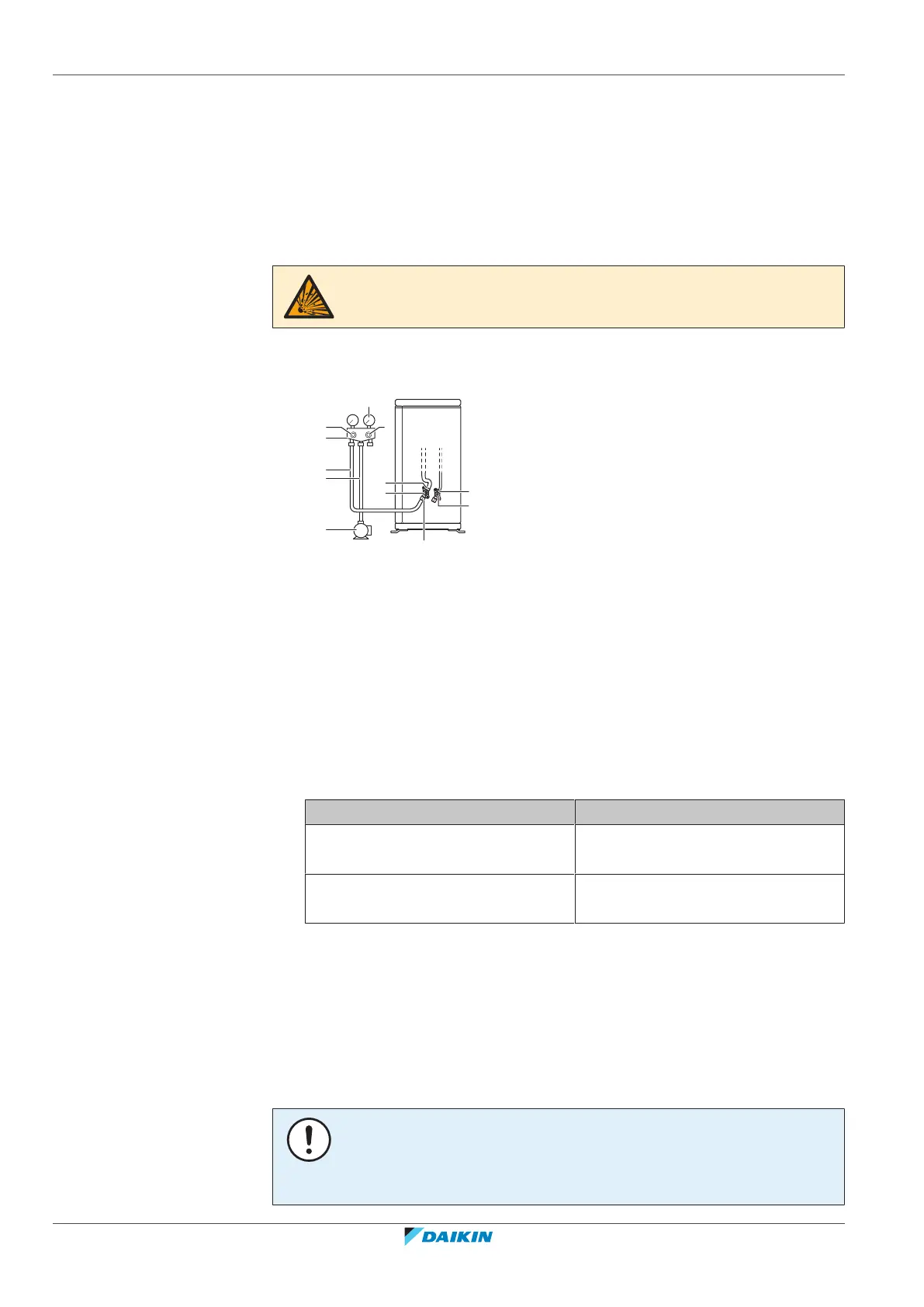

Connect the vacuum pump and manifold as follows:

Connect the vacuum pump and manifold as follows:

a Pressure meter

b Gauge manifold

c Low-pressure valeve (Lo)

d High-pressure valve (Hi)

e Charging hoses

f Vacuum pump

g Service port

h Valve lids

i Gas stop valve

j Liquid stop valve

1 Vacuum the system until the pressure on the manifold indicates −0.1 MPa

(−1bar).

2 Leave as is for 4-5minutes and check the pressure:

If the pressure… Then…

Does not change There is no moisture in the system.

This procedure is finished.

Increases There is moisture in the system. Go

to the next step.

3 Vacuum the system for at least 2hours to a manifold pressure of −0.1MPa

(−1bar).

4 After turning the pump OFF, check the pressure for at least 1hour.

5 If you do NOT reach the target vacuum or CANNOT maintain the vacuum for

1hour, do the following:

▪ Check for leaks again.

▪ Perform vacuum drying again.

NOTICE

Make sure to open the stop valves after installing the refrigerant piping and

performing vacuum drying. Running the system with the stop valves closed may

break the compressor.

Loading...

Loading...