AK-CC550 Manual RS8EN502 © Danfoss 02-2010 33

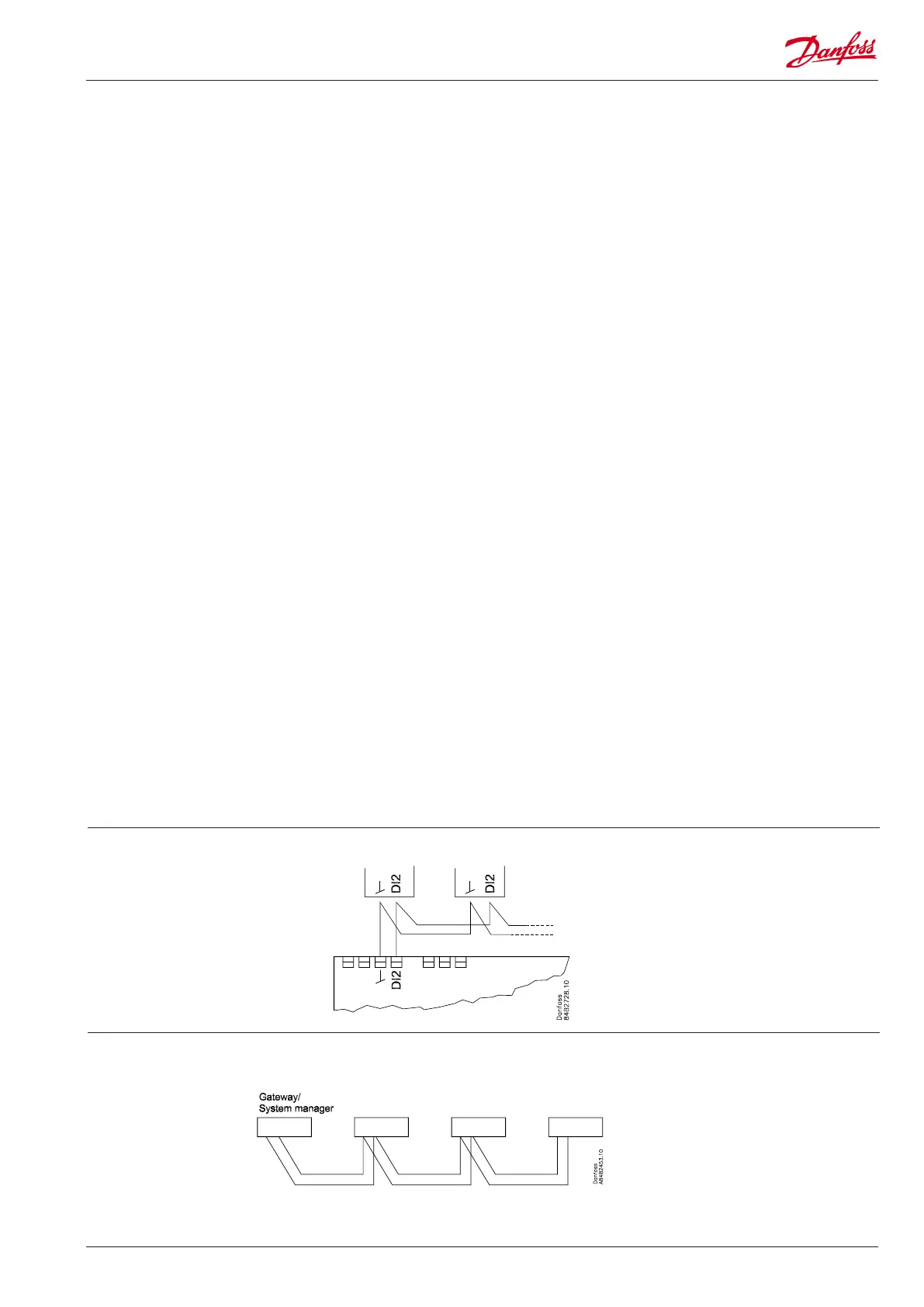

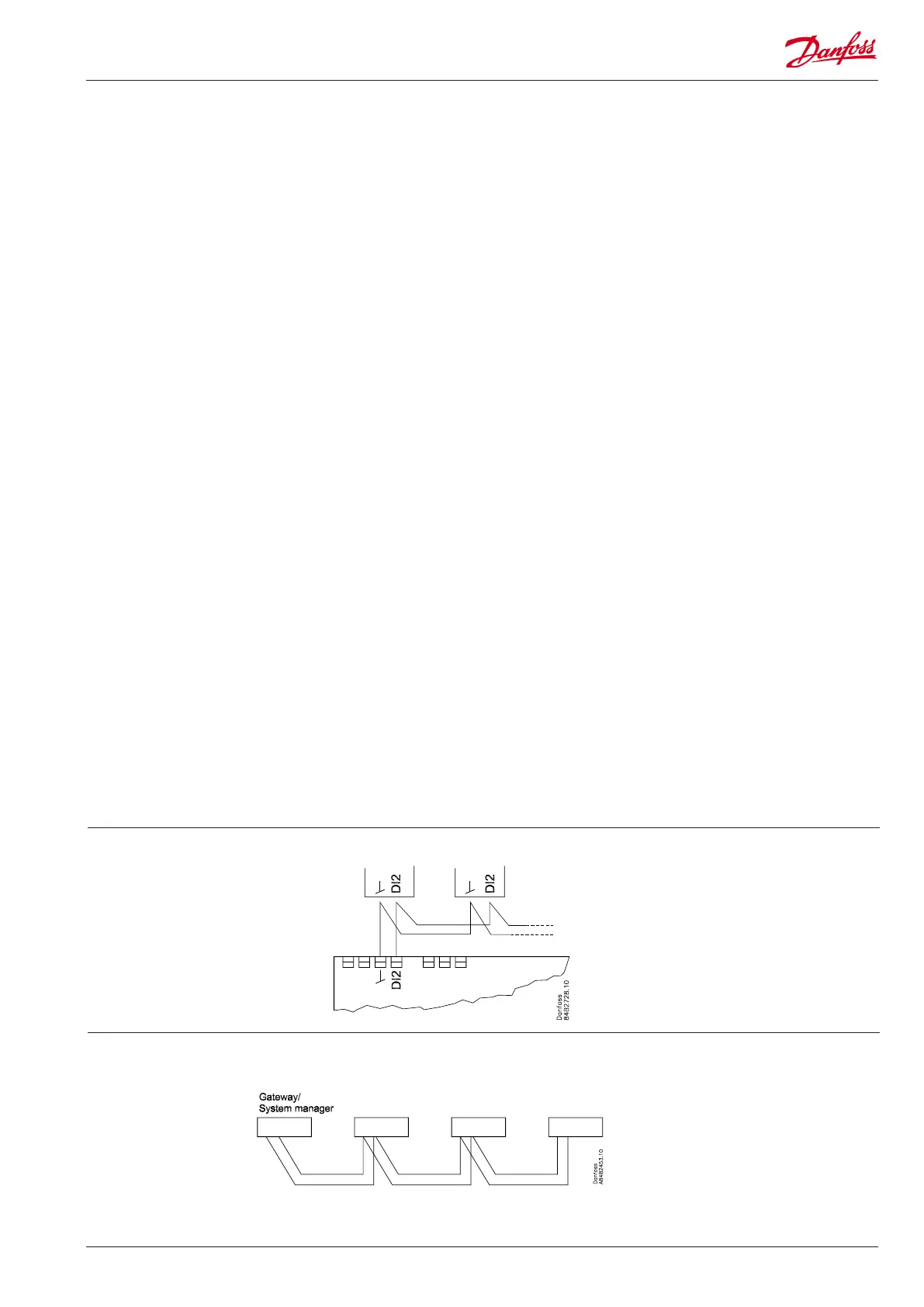

Coordinateddefrostvia

data communication

Coordinateddefrostvia

cable connections

The following controllers can be connected

up in this way:

EKC204A,AK-CC210,AK-CC250,

AK-CC450,AK-CC550,

Refrigeration is resumed when all

controllershave“released”thesignalfor

defrost.

The setting of controllers to coordinate

theirdefrostingtakesplaceinthe

gateway/systemmanager.

Refrigeration is resumed when all

controllershave“released”thesignalfor

defrost.

DO1

ConnectionofexpansionvalvetypeAKVorAKVA.Thecoilmust

be a 230 V a.c. coil.

DO2

Alarm

Thereisaconnectionbetweenterminal7and8inalarm

situations and when the controller is without power.

Rail heat and heating element in drip tray

Thereisconnectionbetweenterminal7and9whenheating

takesplace.

Night blind

Thereisconnectionbetweenterminal7and9whenthenight

blind is up.

Suction line valve

Thereisconnectionbetweenterminal7and9whenthe

suction line must be open.

DO3

Refrigeration, Rail heat, Heat function, Defrost 2

There is connection between terminal 10 and 11 when the

functionmustbeactive.

Heating element in drip tray

There is connection between terminal 10 and 11 when heating

takesplace.

DO4

Defrost

Thereisconnectionbetweenterminal12and14when

defrostingtakesplace.

Hotgas/drainvalve

Thereisconnectionbetweenterminal13and14duringnormal

operation.

Thereisconnectionbetweenterminal12and14whenthehot

gasvalvesmustopen.

DO5

Fan

Thereisconnectionbetweenterminal15and16whenthefan

is on.

DO6

Light relay

Thereisconnectionbetweenterminal17and18whenthe

light must be on.

Rail heat, Compressor 2

Thereisconnectionbetweenterminal17and19whenthe

functionmustbeactive.

DI3

Digital input signal.

Thesignalmusthaveavoltageof0/230VAC.

Thefunctionisdenedino84.

Data communication

Ifdatacommunicationisused,itisimportantthattheinstallation

of the data communication cable is performed correctly.

See separate literature No. RC8AC…

Electric noise

Cablesforsensors,DIinputsanddatacommunicationmust be

keptseparatefromotherelectriccables:

-Useseparatecabletrays

- Keep a distance between cables of at least 10 cm

-LongcablesattheDIinputshouldbeavoided

Installation considerations

Accidentaldamage,poorinstallation,orsiteconditions,cangive

rise to malfunctions of the control system, and ultimately lead to a

plantbreakdown.

Everypossiblesafeguardisincorporatedintoourproductsto

preventthis.However,awronginstallation,forexample,couldstill

present problems. Electronic controls are no substitute for normal,

good engineering practice.

Danfoss will not be responsible for any goods, or plant compo-

nents,damagedasaresultoftheabovedefects.Itistheinstaller's

responsibilitytochecktheinstallationthoroughly,andtotthe

necessarysafetydevices.

Special reference is made to the necessity of signals to the

controller when the compressor is stopped and to the need of

liquidreceiversbeforethecompressors.

YourlocalDanfossagentwillbepleasedtoassistwithfurther

advice,etc.

Max. 10

Loading...

Loading...