Fluid and filter recommendations

To ensure optimum life, perform regular maintenance of the fluid and filter. Contaminated fluid is the

main cause of unit failure. Take care to maintain fluid cleanliness when servicing.

Check the reservoir daily for proper fluid level, the presence of water, and rancid fluid odor. Fluid

contaminated by water may appear cloudy or milky or free water may settle in the bottom of the

reservoir. Rancid odor indicates the fluid has been exposed to excessive heat. Change the fluid and

correct the problem immediately if these conditions occur.

Inspect vehicle for leaks daily. Change the fluid and filter per the vehicle/machine manufacturer's

recommendations or at intervals shown in the table. We recommend first fluid change at 500 hours.

High temperatures and pressures will result in accelerated fluid aging. More frequent fluid changes may

be required.

Change the fluid more frequently if it becomes contaminated with foreign matter (dirt, water, grease,

etc.) or if the fluid is subjected to temperature levels greater than the recommended maximum. Dispose

of used hydraulic fluid properly. Never reuse hydraulic fluid.

Change filters with the fluid or when the filter indicator shows it's necessary. Replace all fluid lost during

filter change.

For detailed filtration information, see Danfoss publication 520L0463 Fluids and Filtration. For

information on biodegradable fluids see Danfoss publication 520L0465 Biodegradable Hydraulic Fluids.

Hazardous material

Warning

Hydraulic fluid contains hazardous material. Avoid contact with hydraulic fluid. Always dispose of used

hydraulic fluid according to state and federal environmental regulations.

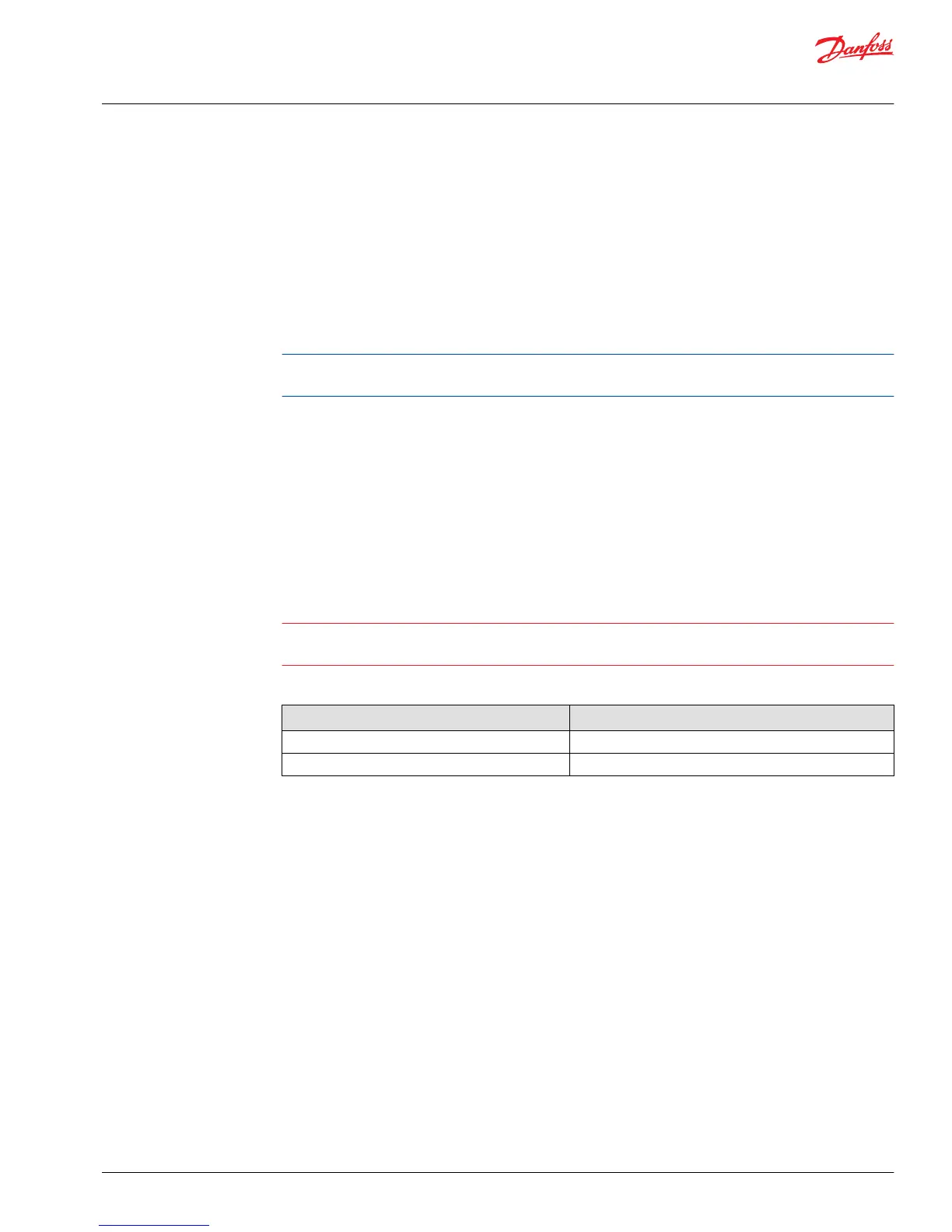

Fluid and filter change interval

Reservoir type Max oil change interval

Sealed 2000 hours

Breather 500 hours

Service Manual

H1 45/53/60/68 Tandem Closed Circuit Axial Piston Pumps

Fluid and filter maintenance

©

Danfoss | June 2018 520L0928 | AX00000103en-US0303 | 25

Loading...

Loading...