Data sheet PAH 2/4/6.3, PAH 10/12.5, PAH 20/25/32 and PAH 50/63/70/80/100 pumps

180R9379 | AQ188686503004en-000801 | PAH 2-12.5 | 21

© Danfoss | DCS (im) | 2022.07© Danfoss | DCS (im) | 2022.07

2. Benets • Zero risk of lubricant contamination:

- Oil lubricants are replaced with the

pumped medium, water, so there is no

contamination risk from the pump.

• Low maintenance costs:

- Ecient design and all-stainless steel

construction ensure exceptionally long

lifetime. When Danfoss specications

are met, service intervals of up to 8,000

hours can be expected. Service is easy,

and can be carried out on site due to

the simple design and few parts.

• Low energy costs:

- The highly ecient axial piston design

provides the lowest energy consump-

tion of any comparable pump on the

market.

• Easy installation:

- The lightest and most compact design

available.

- Pump can be installed horizontally or

vertically.

- No pulsation dampeners necessary due

to extremely low-pressure pulsation.

- Powered by electric motors or combus-

tion engines.

- Suitable for both boosted inlet

pressure and water supply from a tank.

- No need for cooling circuits due to very

high mechanical eciency.

• Certied quality:

Certicates:

ISO 9001, ISO 14001, ITF 16949

ATEX available on request

ABS and DNV GL certications on

request

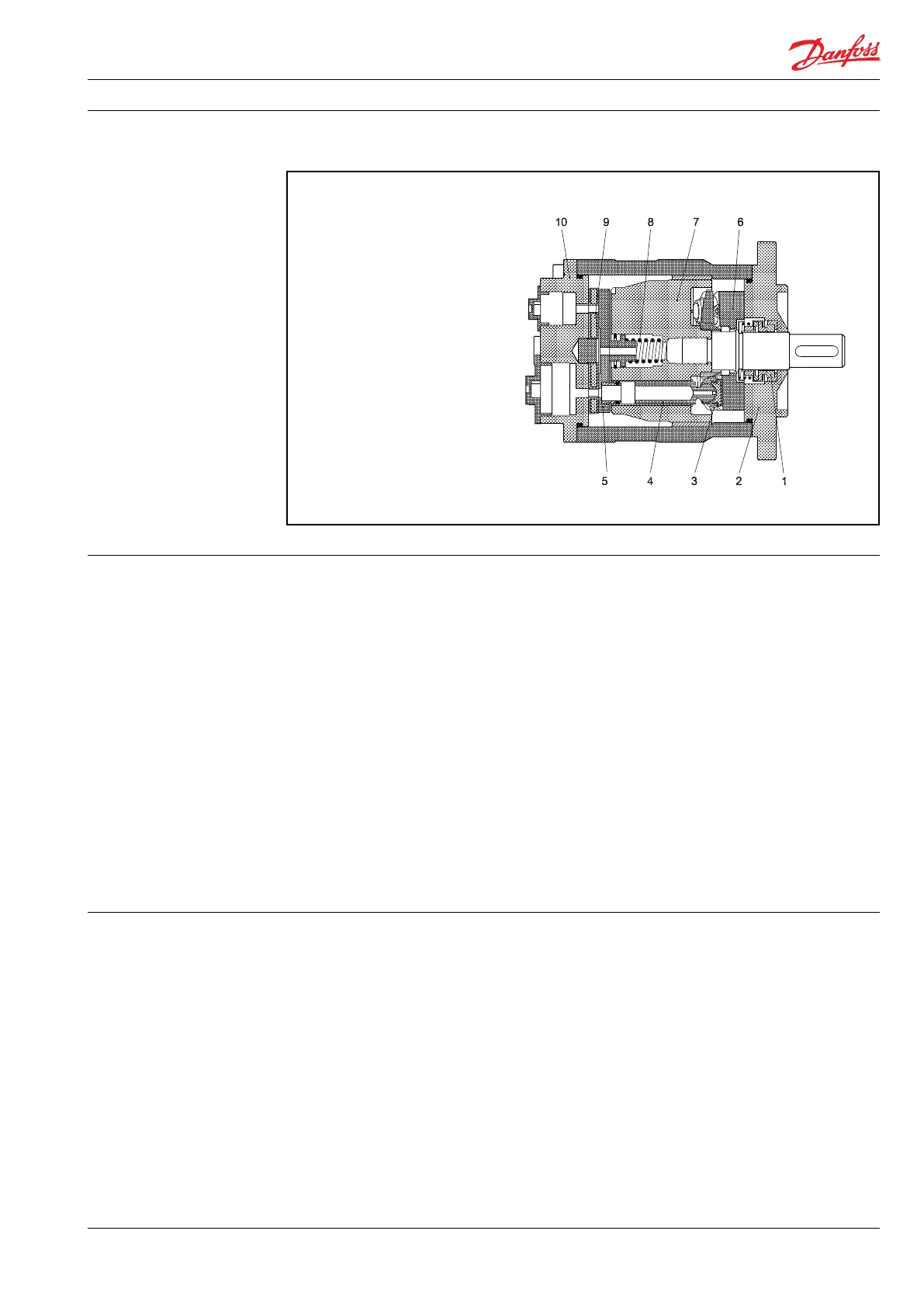

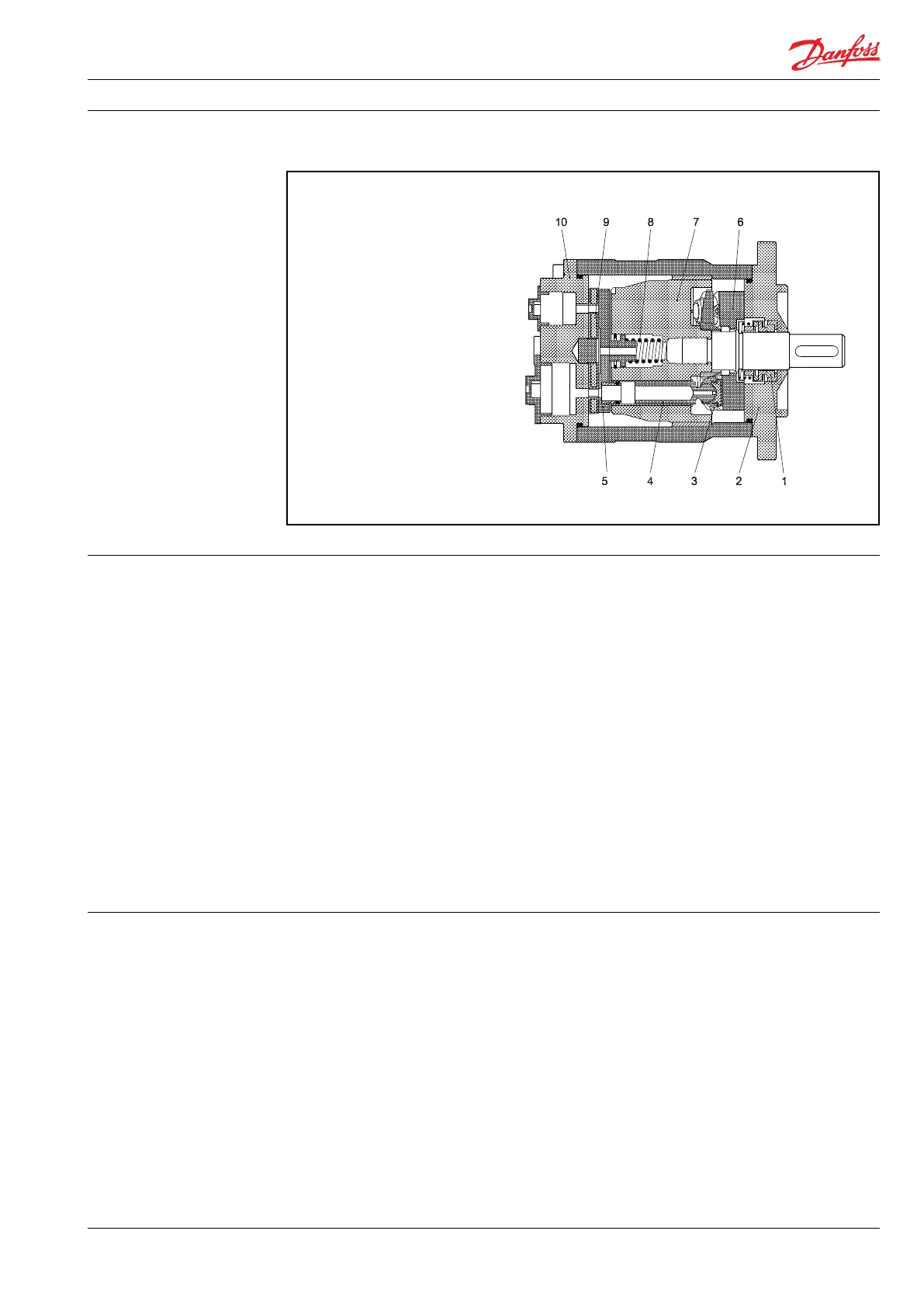

Below sectional drawing is an example of a PAH pump.

3. Application examples • Stationary and mobile hydraulic systems

• High-pressure systems

• Fire ghting

• Flushing and cleaning processes

• Humidication systems

1: Shaft sealing

2: Mounting ange/

housing with bearing

3: Retaining ring

4: Piston/shoe

5: Valve trust plate

6: Swash plate

7: Cylinder barrel8:

8: Spring

9: Port plate

10: Connecting ange

Loading...

Loading...