Data sheet PAH 2/4/6.3, PAH 10/12.5, PAH 20/25/32 and PAH 50/63/70/80/100 pumps

180R9379 | AQ188686503004en-000801 | PAH 2-12.5 | 27

© Danfoss | DCS (im) | 2022.07© Danfoss | DCS (im) | 2022.07

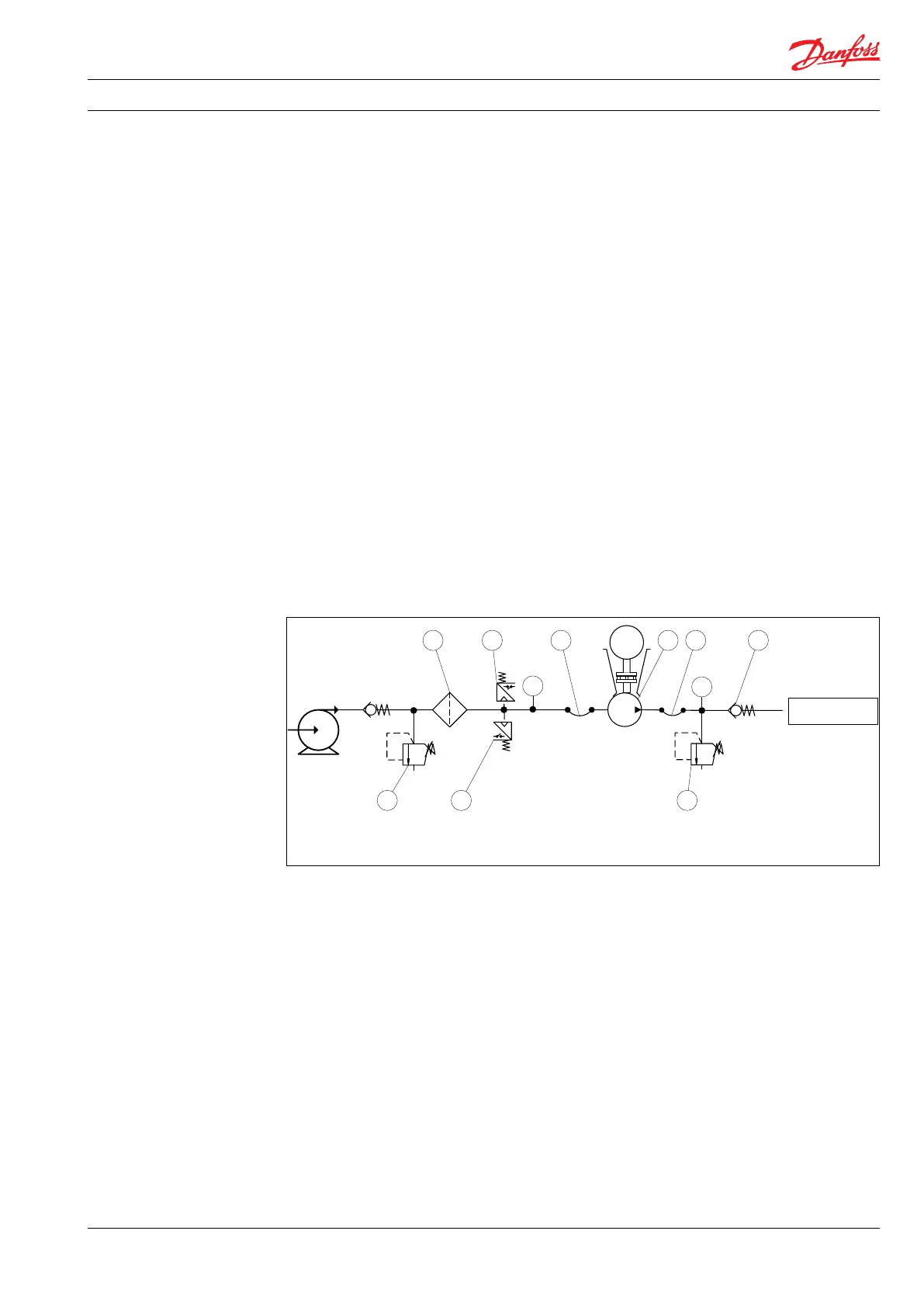

7.3 Open-system design

A Inlet line:

Dimension the inlet line to obtain mini-

mum pressure loss (large ow, minimum

pipe length, minimum number of bends/

connections, ttings with small pressure

losses and restrictions).

B Inlet lter:

Install the inlet lter (1) in front of the PAH

pump (2). Please consult the Danfoss lter

data sheet for guidance on how to select

the right lter.

C Monitoring pressure switch:

Install the monitoring pressure switch (3)

between the lter and the pump inlet. Set

the minimum inlet pressure according to

specications described in item 4, technical

data. The monitoring pressure switch stops

the pump if inlet pressure is lower than the

set minimum pressure.

D Monitoring temperature switch:

Install the monitoring temperature switch

(4) between the lter and the pump, on

either side of the monitoring pressure

switch. Set the temperature value accord-

ing to technical data, item 4. The monitor-

ing temperature switch stops the pump if

inlet temperature is higher than the set

value.

E Hoses:

Always use exible hoses (5) to minimize

vibrations and noise.

F Inlet pressure:

In order to eliminate the risk of cavitation

and other pump damage, pump inlet

pressure must be maintained according to

specications described in item 4, technical

data.

G Non-return valve (6):

Should be installed after the outlet to

prevent pump backspin, which may ruin

the pump.

H Pressure relief valve:

As the Danfoss PAH pump begins to create

pressure and ow immediately after

start-up regardless of any counter pressure,

a pressure relief valve (7) should be

installed to prevent system damage.

Note: If a non-return valve is mounted in the

inlet line, a low-pressure relief valve is also

recommended between the non-return valve

(8) and the pump to protect against high-pres-

sure peaks.

M

2

SYSTEM

1 4 5 5 6

73

PI

PI

8

Loading...

Loading...