Item Description Action

Oil filters Clogged oil filters may result in an insufficient

supply of cool oil to the system.

Inspect the oil filters and verify that they are still

operable. Replace them if necessary.

Machine load Excessive loads or extreme duty cycles can result in

the pump and/or motor operating at speeds and

pressures beyond system design limitations.

Verify that the machine is operating within the

parameters for which it was designed. If necessary,

reduce the load on the machine.

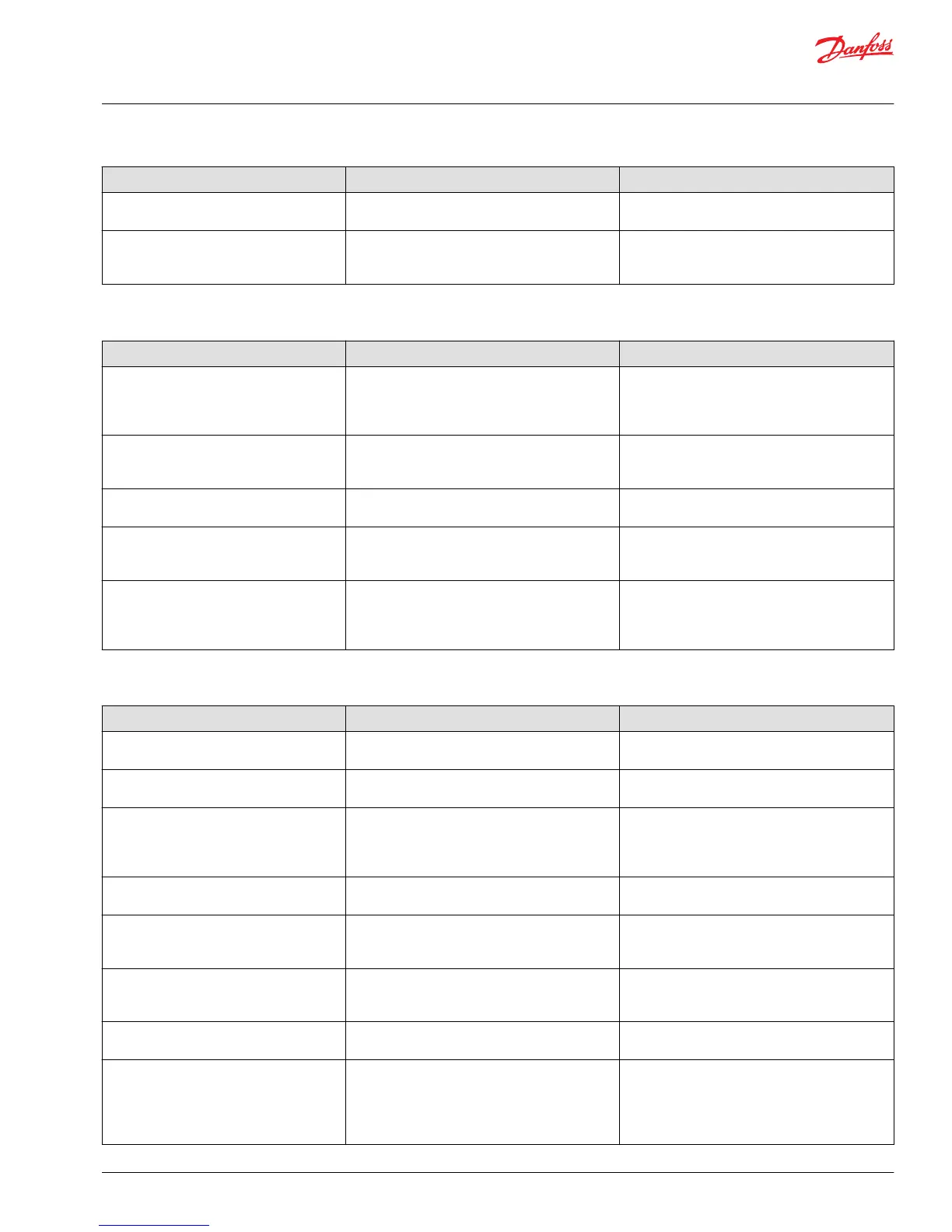

System will not operate in one direction

Item Description Action

Input control signal (linkage, current, or

pressure)

A faulty control signal is being received at the

pump. (MDC - binding or broken linkage, EDC -

faulty or inadequate electrical signal, HDC -

blocked or incorrectly orificed control lines).

Verify that the input signal being received is

correct and identical in both directions. Adjust,

clean, repair, or replace the control module as

necessary.

Displacement limiters (if equipped) The displacement limiters may be improperly

adjusted such that the servo piston is prevented

from moving in one direction.

Verify that the displacement limiters are adjusted

properly.

SCR (system check / relief) valves The SCR valves are malfunctioning or improperly

set.

Verify that the SCR valves are operating properly.

Repair or replace them as necessary.

Pump control A damaged or biased pump control may be

sending a signal commanding the pump to stroke

only in one direction.

Verify that the pump’s control is functioning

properly. Repair or replace it as necessary.

Servo pressure The drain or supply path to one side of the servo

piston may be blocked.

Verify that the servo supply and drain paths are

unobstructed and that each orifice is of the correct

size and free of debris. Clean or repair them as

necessary.

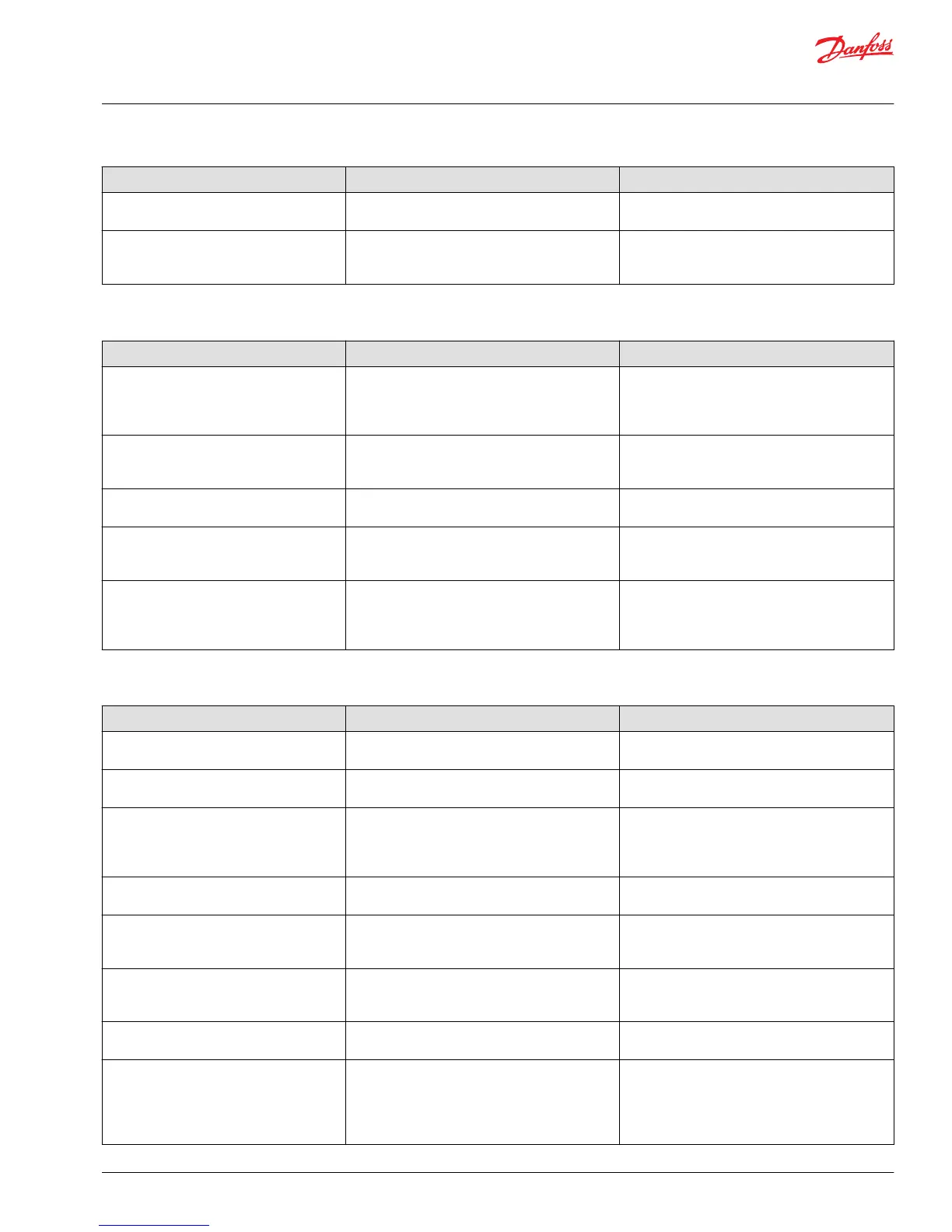

System will not operate in either direction

Item Description Action

Oil level in reservoir There is insufficient hydraulic fluid to supply the

system loop.

Fill the reservoir to the proper level with clean

hydraulic oil.

Displacement limiters Displacement limiters may be improperly adjusted

such that the servo piston is locked in place.

Verify that the displacement limiters are adjusted

to the proper setting.

Input control signal

(linkage, current, or pressure)

A faulty control signal being received at the pump.

(MDC - binding or broken linkage, EDC - faulty or

inadequate electrical signal, HDC - blocked or

incorrectly orificed control lines)

Verify that the input signal being received is

correct and identical in both directions. Adjust,

clean, repair, or replace the input device as

necessary.

Oil filters Clogged oil filters may result in an insufficient

supply of oil to the system.

Inspect the oil filters and verify that they are still

serviceable. Replace them as necessary.

Bypass valve A partially activated bypass valve (one or both)

may result in a cross port leakage.

Verify that the bypass valves are closed and that

the valves are seating properly. Clean, repair, or

replace them as necessary.

Charge pressure

(in neutral)

Charge pressure may be insufficient to recharge

the system loop.

Inspect the charge pump for damage and verify

that the charge pressure relief valve is at the proper

setting. Repair or replace it as necessary.

Charge pressure

(in stroke)

There is low charge pressure resulting from internal

leakage within the system.

Repair or replace the component or components

within the system causing the internal leakage.

Servo pressure There is an insufficient pressure differential across

the servo piston.

Check servo pressures to verify sufficient pressure

delta. Verify that the servo supply and drain paths

are unobstructed and that each orifice is of the

correct size and free of debris. Clean, repair, or

replace them as necessary.

Service Manual

Series 40 M46 Variable Pumps

Troubleshooting

©

Danfoss | September 2017 11026743 | AX00000027en-US0202 | 15

Loading...

Loading...