Data Character (byte)

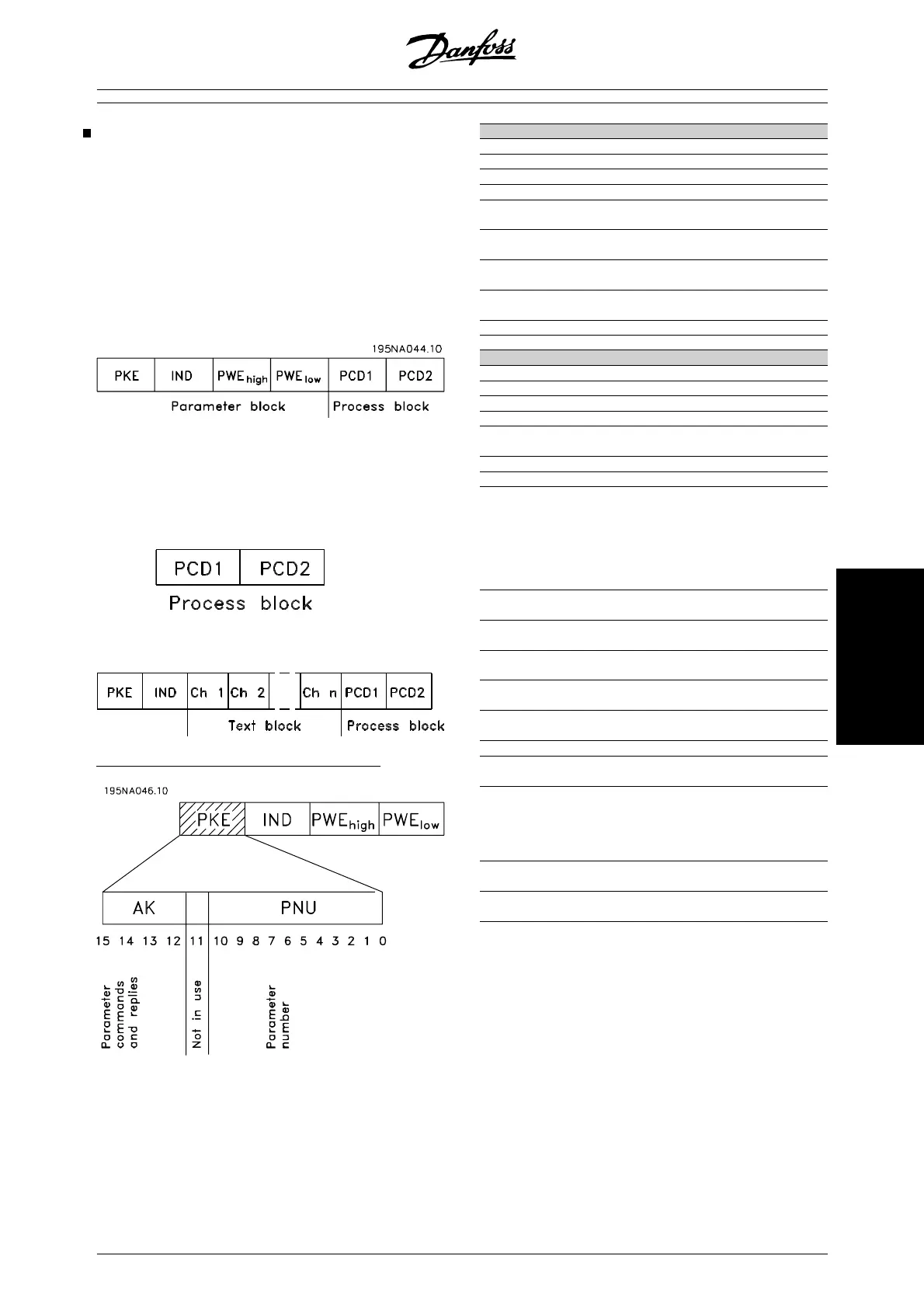

The structure of data blocks depends on the type of

telegram. There are three types of telegram, and the

type of telegram applies for both control telegrams

(masterslave) and response telegrams (slavemaster).

The three types of telegram are:

-

Parameter block, used to transfer parame-

ters between master and slave. The data

block is made up of 12 bytes (6 words) and

also contains the process block.

-

The process block is made up of a data block

of four bytes (2 words) and contains:

-

Control word and reference value

-

Status word and present output fre-

quency (from slave to master)

-

Text block, which is used to read or write texts

via the data block.

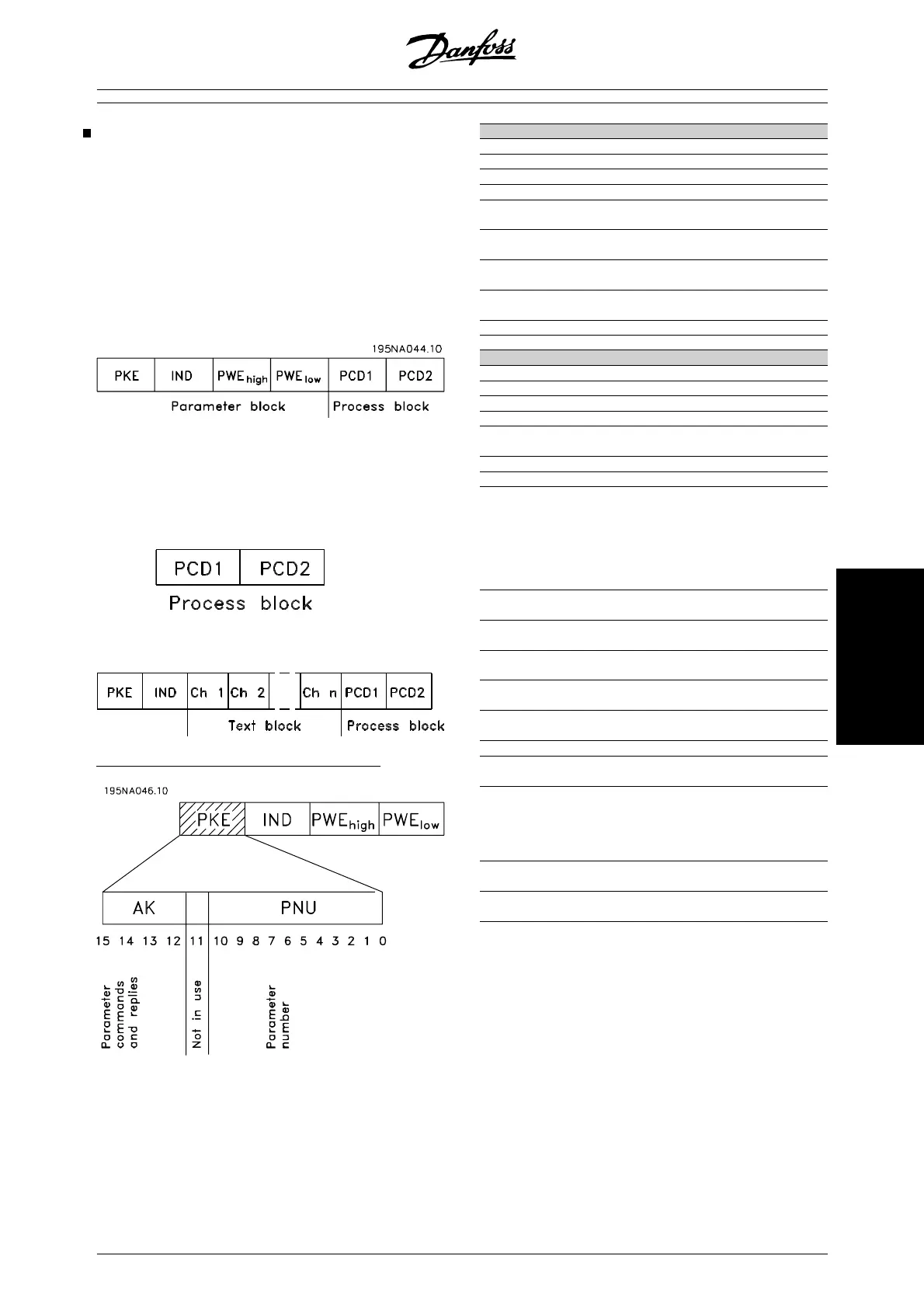

Parameter commands and responses (AK).

Bits no. 12-15 are used to transfer parameter com-

mands from master to slave and the slave's processed

responses back to the master.

Parameter commands masterslave

Bit no.

15

14 13 12 Parameter command

0 0 0 0 No command

0 0 0 1 Read parameter value

0 0 1 0 Write parameter value in RAM

(word)

0 0 1 1 Write parameter value in RAM

(double word)

1 1 0 1 Write parameter value in RAM

and EEprom (double word)

1 1 1 0 Write parameter value in RAM

and EEprom (word)

1 1 1 1 Read/write text

Response slavemaster

Bit no.

Response

15 14 13 12

0 0 0 0 No response

0 0 0 1 Parameter value transferred (word)

0 0 1 0 Parameter value transferred

(double word)

0 1 1 1 Command cannot be performed

1 1 1 1 Text transferred

If the command cannot be performed the slave sends

this response: 0111 Command cannot be performed

and gives the following fault report in the parameter

value (PWE):

Response

(0111)

Fault report

0 The parameter number used

does not exist

1 There is no write access to the

defined parameter

2 Data value exceeds

the parameter's limits

3 The sub index used

does not exist

4 The parameter is not the array type

5 The data type does not match the

defined parameter

17 Data change in the defined para-

meter is not possible in the frequency

converter's present mode.

Certain parameters can only be changed

when the motor is turned off

130 There is no bus access to the

defined parameter

131 Data change is not possible because

factory Setup is selected

MG.27.E2.02 - VLT is a registered Danfoss trademark 113

Programming

Loading...

Loading...