ETR trip 2 (ETR TRIP 2) [6]

ETR warning 3 (ETR WARNING 3) [7]

ETR trip 3 (ETR TRIP 3) [8]

ETR warning 4 (ETR WARNING 4) [9]

ETR trip 4 (ETR TRIP 4) [10]

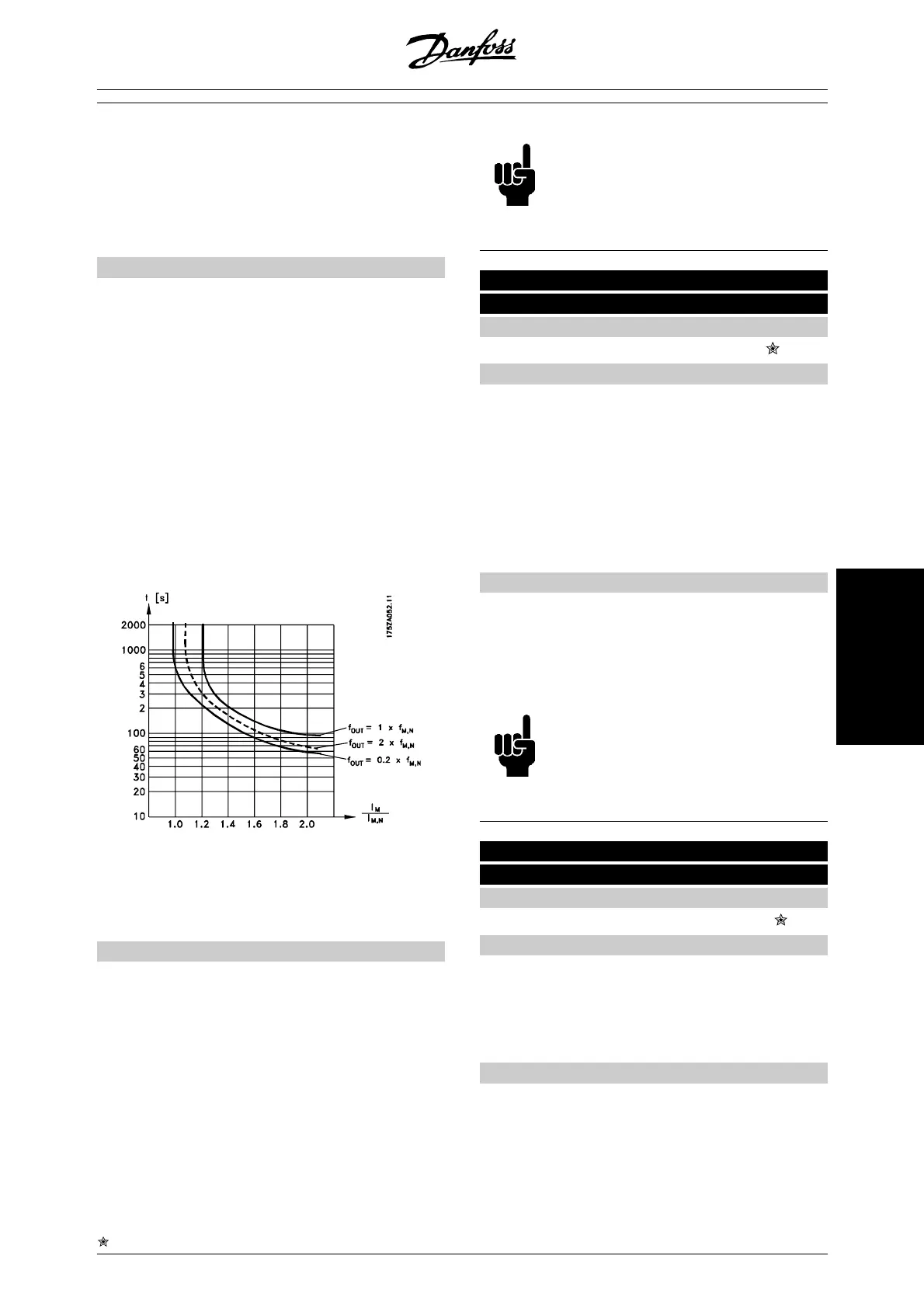

Function:

The frequency converter can monitor the motor tem-

perature in two different ways:

-

Via a PTC thermistor that is mounted on the

motor. The thermistor is connected between

terminal 50 (+10V) and one of the digital input

terminals 18, 19, 27 or 29. See parameter

300 Digital inputs.

-

Thermal load calculation (ETR - Electronic

Thermal Relay), based on present load and

time. This is compared with the rated motor

current I

M,N

and rated motor frequency f

M,N

.

The calculations take into account the need

for lower loading at low speeds due to the

motor's internal ventilation being reduced.

ETR functions 1-4 do not begin to calculate the load

until you switch to the Setup in which they have been

selected. This means that you can use the ETR func-

tion even when changing between two or more motors.

Description of choice:

Select No protection [0] if you do not want a warning

or trip when a motor is overloaded.

Select Thermistor warning [1] if you want a warning

when the connected thermistor becomes too hot.

Select Thermistor trip [2] if you want a trip when the

connected thermistor becomes too hot.

Select ETR warning 1-4 if you want a warning when the

motor is overloaded according to the calculations. You

can also programme the frequency converter to give a

warning signal via one of the digital outputs. Select

ETR Trip 1-4 if you want a trip when the motor is over-

loaded according to the calculations.

NB!

This function cannot protect the individual

motors in the case of motors linked in par-

allel.

130 Start frequency

(Start frequency)

Value:

0.0 - 10.0 Hz

0.0 Hz

Function:

The start frequency is active for the time set in param-

eter 120 Start delay, after a start command. The output

frequency will 'jump' to the next preset frequency. Cer-

tain motors, such as conical anchor motors, need an

extra voltage/start frequency (boost) at start to disen-

gage the mechanical brake. To achieve this parame-

ters 130 Start frequency and 131 Initial voltage are

used.

Description of choice:

Set the required start frequency. It is a precondition

that parameter 121 Start function, is set to Start fre-

quency/voltage clockwise [3] or Start frequency voltage

in reference direction [4] and that in parameter 120 Start

delay a time is set and a reference signal is present.

NB!

If parameter 123 is set higher than param-

eter 130, the start delay function (param-

eter 120 and 121) will be skipped.

131 Initial voltage

(INITIAL VOLTAGE)

Value:

0.0 - 200.0 V

0.0 V

Function:

Initial voltage is active for the time set in parameter 120

Start delay , after a start command. This parameter can

be used for example for lifting/dropping applications

(conical anchor motors).

Description of choice:

Set the required voltage necessary to cut out the me-

chanical brake. It is assumed that parameter 121 Start

function, is set to Start frequency/voltage clockwise [3]

or Start frequency/voltage in reference direction [4] and

= factory setting, () = display text, [] = value for use in communication via serial communication port

MG.27.E2.02 - VLT is a registered Danfoss trademark 73

Programming

Loading...

Loading...