ALARM 31, Motor phase V missing

Motor phase V between the frequency converter and the

motor is missing.

Remove power from the frequency converter and check

motor phase V.

ALARM 32, Motor phase W missing

Motor phase W between the frequency converter and the

motor is missing.

Remove power from the frequency converter and check

motor phase W.

ALARM 33, Inrush fault

Too many power-ups have occurred within a short time

period. Let the unit cool to operating temperature.

WARNING/ALARM 34, communication fault

The fieldbus on the communication option card is not

working.

WARNING/ALARM 36, Mains failure

This warning/alarm is only active if the supply voltage to

the frequency converter is lost and 14-10 Mains Failure is

NOT set to [0] No Function.

Troubleshooting

•

Check the fuses to the frequency converter and

mains power supply to the unit

ALARM 38, Internal fault

When an internal fault occurs, a code number defined in

the Table 6.4 is displayed.

Troubleshooting

•

Cycle power

•

Check that the option is properly installed

•

Check for loose or missing wiring

Contact the Danfoss supplier or service department if

required. Note the code number for further trouble-

shooting directions.

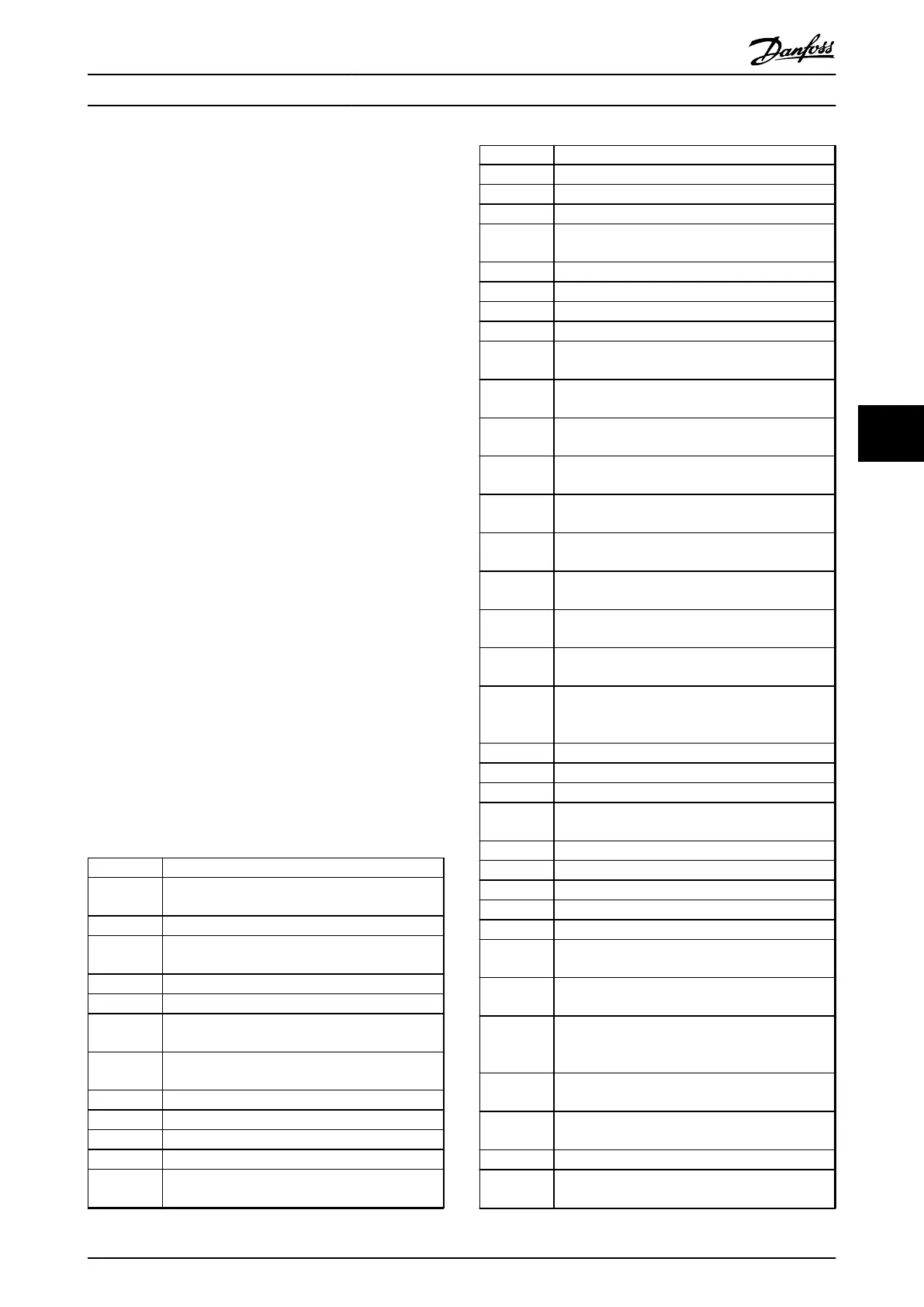

No.

Text

0 Serial port cannot be initialised. Contact the

Danfoss supplier or Danfoss Service Department.

256-258 Power EEPROM data is defective or too old.

512 Control board EEPROM data is defective or too

old.

513 Communication time out reading EEPROM data.

514 Communication time out reading EEPROM data.

515 Application oriented control cannot recognize the

EEPROM data.

516 Cannot write to the EEPROM because a write

command is on progress.

517 Write command is under time out.

518 Failure in the EEPROM.

519 Missing or invalid barcode data in EEPROM.

783 Parameter value outside of min/max limits.

1024-1279 A centelegram that has to be sent couldn't be

sent.

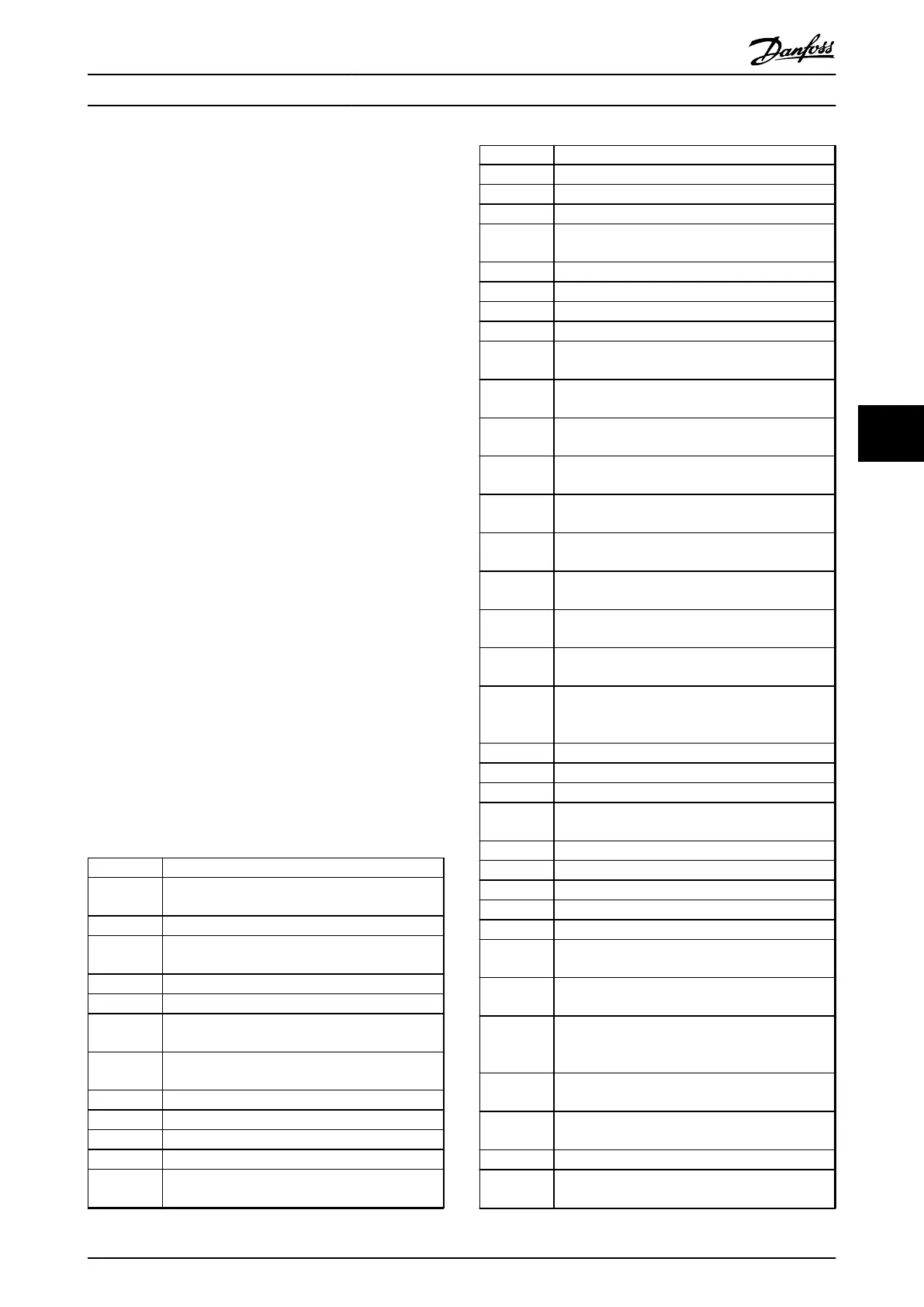

No. Text

1281 Digital signal processor flash timeout.

1282 Power micro software version mismatch.

1283 Power EEPROM data version mismatch.

1284 Cannot read digital signal processor software

version.

1299 Option SW in slot A is too old.

1300 Option SW in slot B is too old.

1301 Option SW in slot C0 is too old.

1302 Option SW in slot C1 is too old.

1315 Option SW in slot A is not supported (not

allowed).

1316 Option SW in slot B is not supported (not

allowed).

1317 Option SW in slot C0 is not supported (not

allowed).

1318 Option SW in slot C1 is not supported (not

allowed).

1379 Option A did not respond when calculating

platform version.

1380 Option B did not respond when calculating

platform version.

1381 Option C0 did not respond when calculating

platform version.

1382 Option C1 did not respond when calculating

platform version.

1536 An exception in the application oriented control is

registered. Debug information written in LCP.

1792 DSP watchdog is active. Debugging of power part

data, motor oriented control data not transferred

correctly.

2049 Power data restarted.

2064-2072 H081x: option in slot x has restarted.

2080-2088 H082x: option in slot x has issued a powerup-wait.

2096-2104 H983x: option in slot x has issued a legal

powerup-wait.

2304 Could not read any data from power EEPROM.

2305 Missing SW version from power unit.

2314 Missing power unit data from power unit.

2315 Missing SW version from power unit.

2316 Missint lo_statepage from power unit.

2324 Power card configuration is determined to be

incorrect at power up.

2325 A power card has stopped communicating while

main power is applied.

2326 Power card configuration is determined to be

incorrect after the delay for power cards to

register.

2327 Too many power card locations have been

registered as present.

2330 Power size information between the power cards

does not match.

2561 No communication from DSP to ATACD.

2562 No communication from ATACD to DSP (state

running).

Warnings and Alarms

VLT

®

Automation Drive FC 300 Operating Instructions

MG33U402 - Rev. 2013-12-16 113

6 6

Loading...

Loading...