24 V DC Power Supply

•

5 A, 120 W, 24 V DC

•

Protected against output over-current, overload,

short circuits, and over-temperature

•

For powering customer-supplied accessory

devices such as sensors, PLC I/O, contactors,

temperature probes, indicator lights, and/or other

electronic hardware

•

Diagnostics include a dry DC-ok contact, a green

DC-ok LED, and a red overload LED

External Temperature Monitoring

Designed for monitoring temperatures of external system

components, such as the motor windings and/or bearings.

Includes eight universal input modules plus two dedicated

thermistor input modules. All ten modules are integrated

into the frequency converter’s safe-stop circuit and can be

monitored via a fieldbus network (requires the purchase of

a separate module/bus coupler).

Universal inputs (8)

Signal types:

•

RTD inputs (including Pt100), 3-wire or 4-wire

•

Thermocouple

•

Analog current or analog voltage

Additional features:

•

One universal output, configurable for analog

voltage or analog current

•

Two output relays (N.O.)

•

Dual-line LC display and LED diagnostics

•

Sensor lead wire break, short-circuit, and incorrect

polarity detection

•

Interface setup software

Dedicated thermistor inputs (2)

Features:

•

Each module capable of monitoring up to six

thermistors in series

•

Fault diagnostics for wire breakage or short-

circuits of sensor leads

•

ATEX/UL/CSA certification

•

A third thermistor input can be provided by the

PTC Thermistor Option Card MCB 112, if

necessary

3.3

Electrical Installation

3.3.1 Transformer Selection

The frequency converter must be used with a 12-pulse

isolation transformer.

3.3.2

Power Connections 12-Pulse Drives

Cabling and Fusing

NOTE

Cables General

All cabling must comply with national and local

regulations on cable cross-sections and ambient

temperature. UL applications require 75° C copper

conductors. 75° and 90° C copper conductors are thermally

acceptable for the frequency converter to use in non UL

applications.

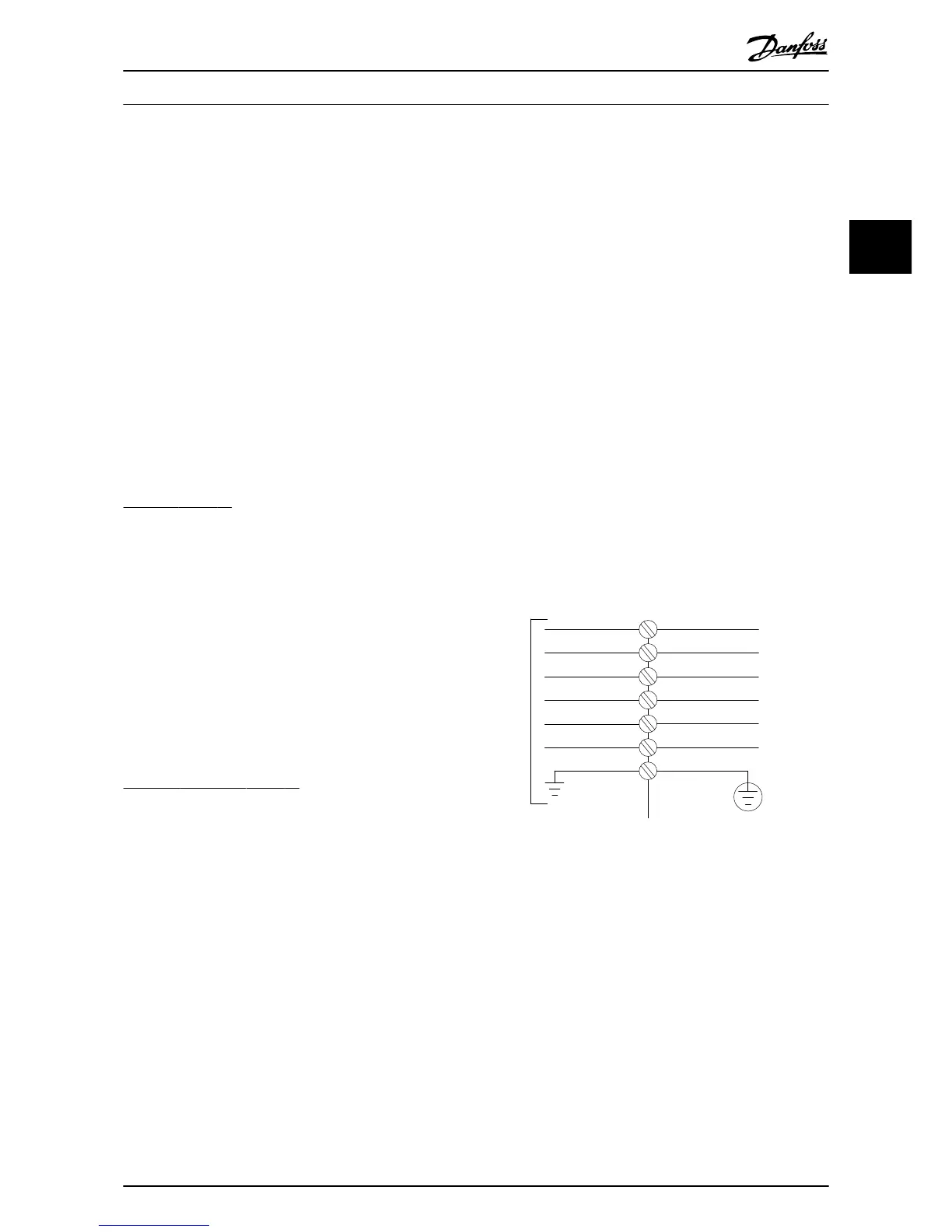

The power cable connections are situated as in

Illustration 3.21. Dimensioning of cable cross section must

be done in accordance with the current ratings and local

legislation. See 5.1 General Specifications for details.

For protection of the frequency converter, the

recommended fuses must be used or the unit must be

with built-in fuses. Recommended fuses can be seen in

3.3.13 Fuses . Always ensure that proper fusing is made

according to local regulation.

The mains connection is fitted to the mains switch if this is

included.

Illustration 3.21

NOTE

The motor cable must be screened/armoured. If an

unscreened/unarmoured cable is used, some EMC

requirements are not complied with. Use a screened/

armoured motor cable to comply with EMC emission

specifications. For more information, see EMC Specifications

in the Design Guide, MG11BXYY and the FC 300 Design

Guide, MG33BXYY.

See 5.1 General Specifications for correct dimensioning of

motor cable cross-section and length.

How to Install

VLT

®

Automation Drive FC 300 12-Pulse

Operating Instructions High Power

MG34Q202 - VLT

®

is a registered Danfoss trademark 27

3

3

Loading...

Loading...