VLT

®

FCD Series

■ Technology

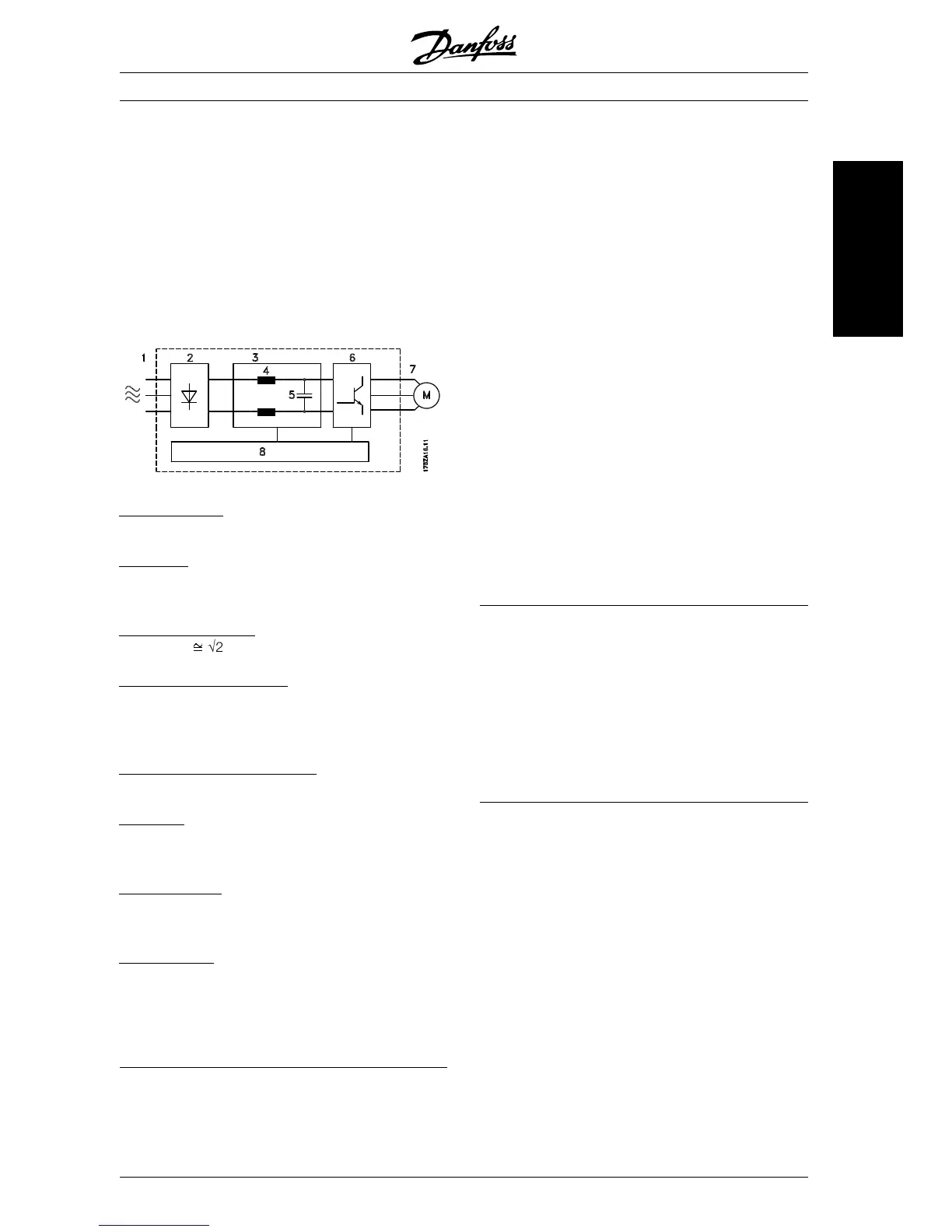

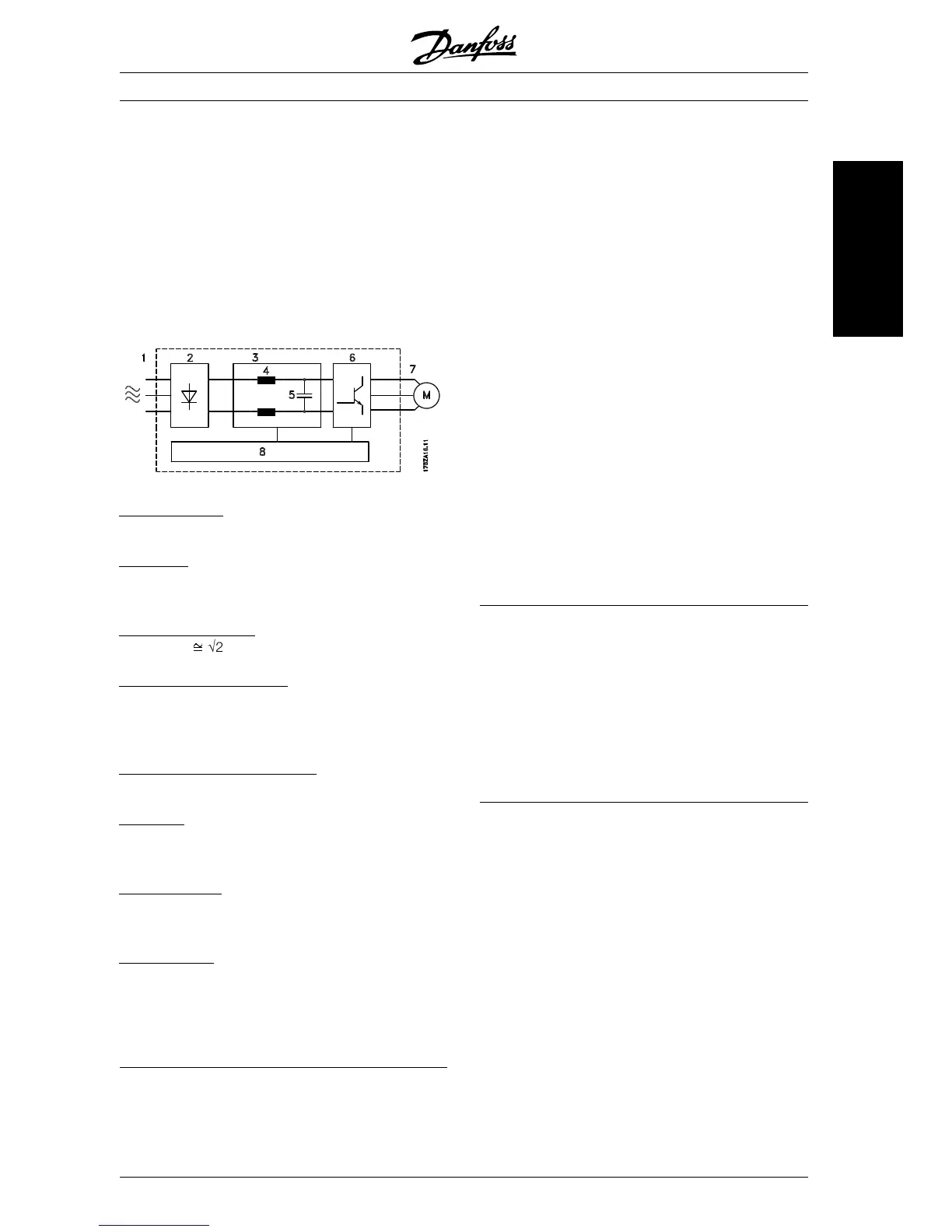

■ Control principle

A frequency converter rectifies AC voltage from the

mains supply into DC voltage, following which it

changes this voltage to an AC voltage with variable

amplitude and frequency.

The motor thus receives a variable voltage and fre-

quency, which enables infinitely variable speed

control of three-phase, standard AC motors.

1. Mains voltage

3 x 380 - 480 V AC, 50 / 60 Hz.

2

. Rectifier

Three-phase rectifier bridge which rectifies AC volt-

age into DC voltage.

3

. Intermediate circuit

DC voltage

=

√2 x mains voltage [V].

4

. Intermediate circuit coils

Evens out the intermediate circuit current and limits

the load on mains and components (mains trans-

former, cables, fuses and contactors).

5

. Intermediate circuit capacitor

Evens out the intermediate circuit voltage.

6

. Inverter

Converts DC voltage into a variable AC voltage with

a variable frequency.

7

. Motor voltage

Variable AC voltage depending on supply voltage.

Variable frequency: 0.2 - 132 / 1 - 1000 Hz.

8

. Control card

Here is the computer that controls the inverter which

generates the pulse pattern by which the DC voltage

is converted into variable AC voltage with a variable

frequency.

■ The decentral concept

The FCD 300 Adjustable speed drive is designed for

decentral mounting, e.g. in the food and beverage

industry, in the automotive industry, or for other ma-

terial handling applications.

With the FCD 300 it is possible to utilize the cost

saving potential by placing the power electronics de-

centrally, and thus make the central panels obsolete

saving cost, space and effort for installation and

wiring.

The unit is flexible in its mounting options for as well

stand alone mounting and motor mounting. It is also

possible to have the unit pre-mounted on a Danfoss

Bauer geared motor (3 in one solution). The basic

design with a plugable electronic part and a flexible

and “spacious” wiring box is extremely service-

friendly and easy to change electronics without the

need for unwiring.

The FCD 300 is a part of the VLT frequency con-

verter family, which means similar funcionality ,

programming, and operating as the other family

members.

■ Cleaning

The enclosure (IP66/NEMA type 4x indoor) will offer

protection against dirt and water ingress, and is de-

signed suitable for cleaning as performed in food and

beverage plants with the concentrations of cleaning

solvent as recommended by the manufacturer. High

pressure cleaning in very short distance or long time

with hot water may damage gaskets and lables.

■ FCD 300 control principle

A frequency converter is an electronic unit which is

able to infinitely variably control the rpm of an AC

motor. The frequency converter governs the motor

speed by converting the regular voltage and fre-

quency from mains, e.g. 400 V / 50 Hz, into variable

magnitudes. Today the frequency converter con-

trolled AC motor is a natural part of all types of

automated plants.

The FCD 300 Series has an inverter control system

called VVC (Voltage Vector Control). VVC controls

an induction motor by energizing with a variable fre-

quency and a voltage suitable for it. If the motor load

changes, so does its energizing and speed. That is

why the motor current is measured on an ongoing

MG.04.A1.02 - VLT is a registered Danfoss trade mark

5

Introduction to FCD 300

Loading...

Loading...