MCD 200 Design Guide

MG.17.C3.02 – VLT is a registered Danfoss trademark 23

Soft Start Application Guide

• Starter Current Rating: Maximum FLC rating

of the motor to be connected to the soft

starter given the operating parameters

specified by the remaining items in the AC53a

code.

• Start Current: The maximum start current that

will be drawn during start.

• Start Time: The time taken for the motor to

accelerate.

• On-load Duty Cycle: The percentage of each

operating cycle that the soft starter will run.

• Starts Per Hour: The number of operating

cycles per hour.

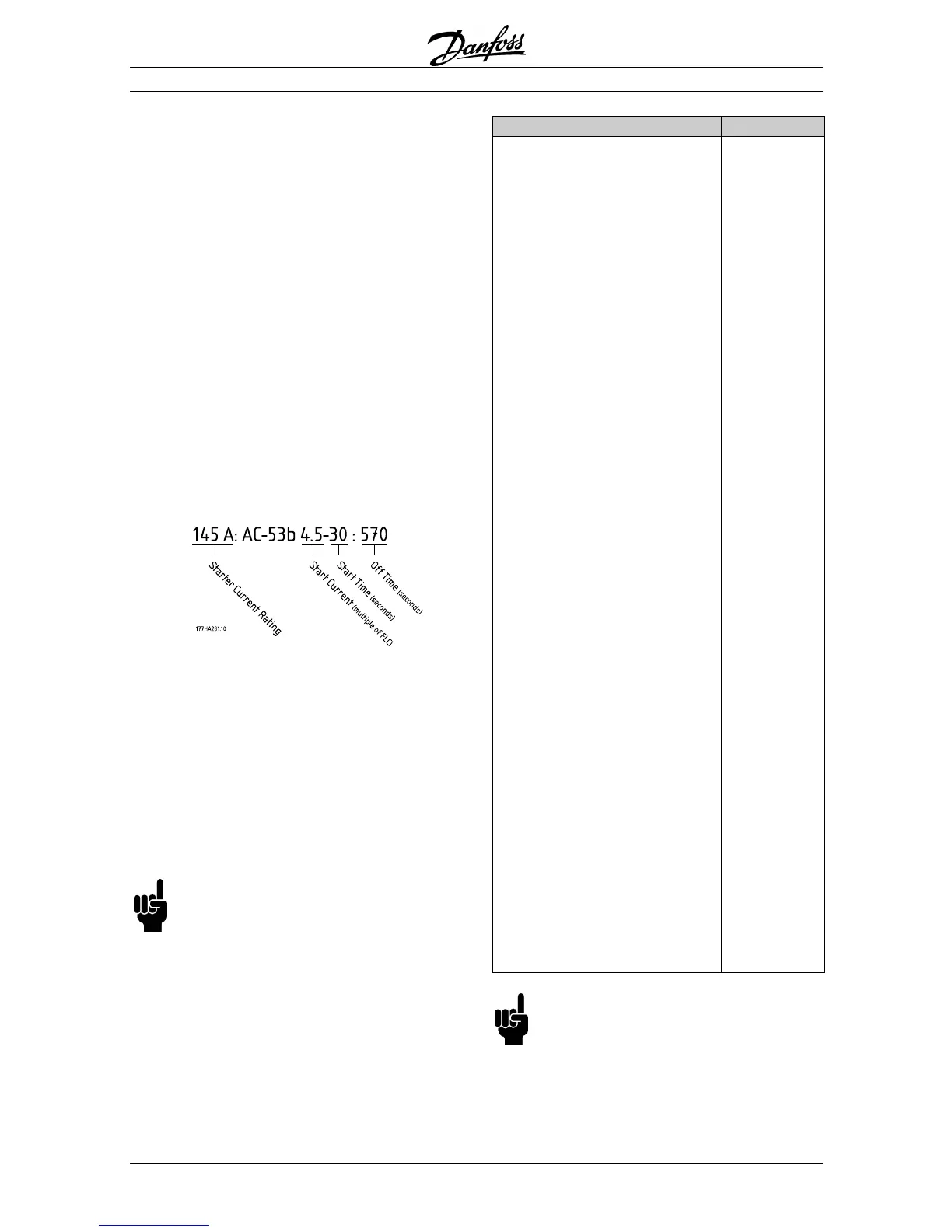

2. AC53b: for soft starters used with bypass

contactors.

For example, the following AC53b code describes

a soft starter which, when bypassed, is capable of

supplying 145 A run current and a start current of

4.5 x FLC for 30 seconds with a minimum of 570

seconds between the end of one start and the

commencement of the next.

In summary, a soft starter has many current ratings.

These current ratings are dependent on the start

current and operational performance required by the

application.

To compare the current rating of different soft starters

it is important to ensure that operating parameters are

identical.

■

Model Selection

NB!:

To fully understand the model selection

procedures it is important to have a good

knowledge of the fundamental principles of soft starter

ratings. See Understanding Soft Starter Ratings.

To select the correct MCD 200 model :

1. Determine whether the application requires a

normal duty or a heavy duty rating. The table

below can be used as a guide.

2. See the tables in Ratings and select an MCD

200 model with an FLC rating greater than

that of the motor.

Application Duty

General & Water

Agitator Normal

Centrifugal Pump

Normal

Compressor (Screw, unloaded)

Normal

Compressor (Reciprocating, unloaded)

Normal

Conveyor

Normal

Fan (damped)

Normal

Fan (undamped)

Heavy

Mixer

Heavy

Positive Displacement Pump

Normal

Submersible Pump

Normal

Metals & Mining

Belt Conveyor Heavy

Dust Collector

Normal

Grinder

Normal

Hammer Mill Heavy

Rock Crusher

Normal

Roller Conveyor

Normal

Roller Mill Heavy

Tumbler Normal

Wire Draw Machine Heavy

Food Processing

Bottle Washer

Normal

Centrifuge

Normal

Dryer

Heavy

Mill

Heavy

Palletiser

Heavy

Separator

Heavy

Slicer Normal

Pulp and Paper

Dryer

Heavy

Re-pulper

Heavy

Shredder

Heavy

Petrochemical

Ball Mill Heavy

Centrifuge Normal

Extruder Heavy

Screw Conveyor Normal

Transport & Machine Tool

Ball Mill Heavy

Grinder

Normal

Material Conveyor

Normal

Palletiser Heavy

Press Normal

Roller Mill Heavy

Rotary Table Normal

Lumber & Wood products

Bandsaw Heavy

Chipper Heavy

Circular Saw Normal

Debarker

Normal

Edger

Normal

Hydraulic Power Pack

Normal

Planer

Normal

Sander

Normal

NB!:

The above start current requirements are

typical and appropriate in most circumstances.

However, start torque requirements and performance

of motors and machines do vary. Please contact

Danfoss if the application requires duties other than

listed in this manual.

Loading...

Loading...