3

Fig. 4

Fig. 6

Fig. 5

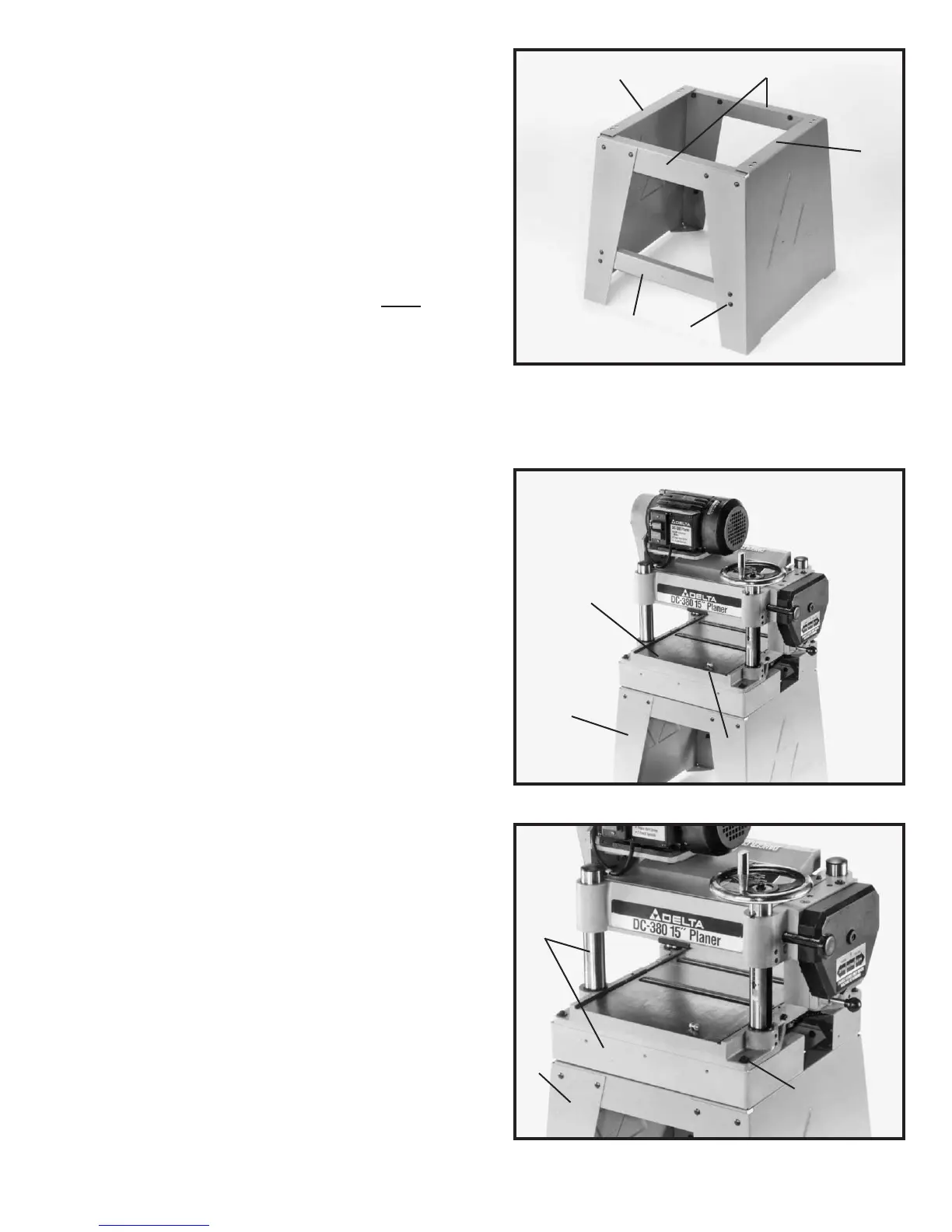

ASSEMBLING PLANER TO STAND

1. Carefully lift the planer (E) Fig. 5, onto the stand (B) as

shown. CAUTION: EXTREME CARE SHOULD BE TAKEN

WHEN LIFTING THE PLANER ONTO THE STAND AS

THE CUTTERHEAD KNIVES ARE EXTREMELY SHARP

AND THE PLANER IS VERY HEAVY. IF IT IS NOT DONE

MECHANICALLY, A MINIMUM OF FOUR PEOPLE ARE

REQUIRED TO MANUALLY LIFT THE MACHINE.

2. Align the four holes in the bottom of the planer (E)

Fig. 5, with the mounting holes in the top of stand (B), and

mount the planer to the stand with four M8 x 30MM hex

head screws (F) Fig. 5, lockwashers and flange nuts.

NOTE: Screws (F) Fig. 6, one of which is shown, are

started upward from the inside of stand (B). Later planer

models may not need flange nuts.

3. Once the planer is assembled to the stand, push

down on top of the planer so the legs of the stand adjust

to the floor surface. Tighten all stand mounting

hardware.

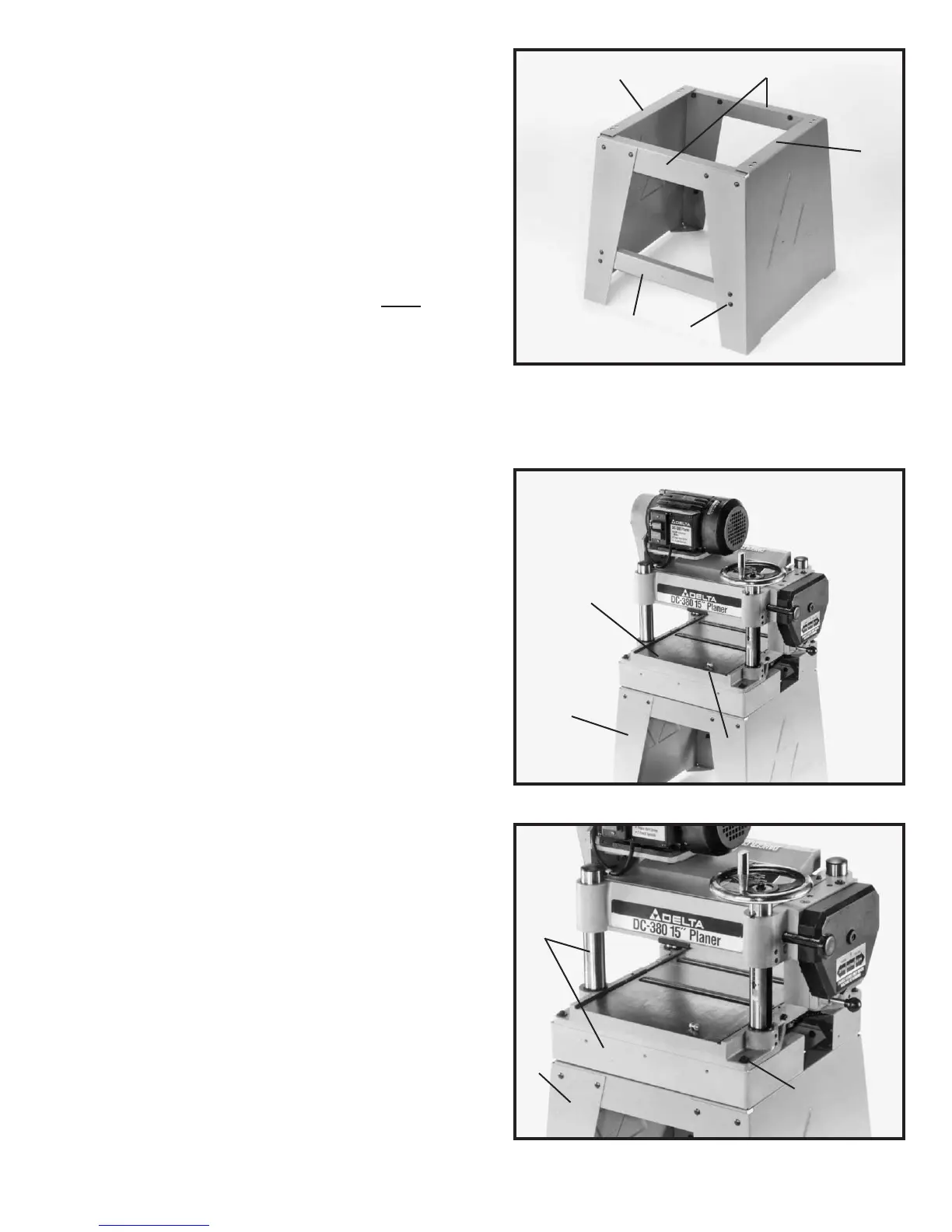

ASSEMBLING STAND

1. Assemble the two longer support brackets (A) Fig. 4,

one of which is shown, to the inside of end panels (B) with

eight 5/16-18 x 3/4″ carriage head screws (C), flat

washers, and 5/16-18 hex nuts. DO NOT COMPLETELY

TIGHTEN HARDWARE AT THIS TIME.

2. Assemble the two shorter support brackets (D) Fig. 4,

to the inside top of end panels (B) with the remaining

eight 5/16-18 x 3/4″ carriage head screws (C), flat washers

and 5/16-18 hex nuts. DO NOT COMPLETELY TIGHTEN

HARDWARE AT THIS TIME. NOTE: Make certain the top

lip of support brackets (D) are positioned under the top

lips of end panels (B) as shown in Fig. 4.

B

D

B

A

C

E

B

E

B

F

F

Loading...

Loading...