5

ENGLISH

5) Service

a ) Have your power tool serviced by a qualified repair person

using only identical replacementparts. This will ensure that the

safety of the power tool ismaintained.

Additional Safety Instructions for Rotary Hammers

• Wear earprotectors. Exposure to noise can cause hearingloss.

• Use auxiliary handle

3

, if supplied with thetool. Loss of control can

cause personalinjury.

• Hold power tool by insulated gripping surfaces, when performing

an operation where the cutting accessory may contact hidden

wiring or its owncord. Cutting accessory contacting a “live” wire

may make exposed metal parts of the power tool “live” and could

give the operator an electricshock.

WARNING: We recommend the use of a residual current device with a

residual current rating of 30mA orless.

Residual Risks

In spite of the application of the relevant safety regulations and the

implementation of safety devices, certain residual risks cannot beavoided.

These are:

• Impairment ofhearing.

• Risk of personal injury due to flyingparticles.

• Risk of burns due to accessories becoming hot duringoperation.

• Risk of personal injury due to prolongeduse.

Electrical Safety

The electric motor has been designed for one voltageonly. Always check

that the power supply corresponds to the voltage on the ratingplate.

Your

serviceorganisation.

Mains Plug Replacement

(U.K. & Ireland Only)

If a new mains plug needs to be fitted:

• Safely dispose of the oldplug.

• Connect the brown lead to the live terminal in theplug.

• Connect the blue lead to the neutralterminal.

WARNING: No connection is to be made to the earthterminal.

Follow the fitting instructions supplied with good qualityplugs.

Recommended fuse: 13A.

Using an Extension Cable

An extension cord should not be used unless absolutelynecessary. Use an

approved extension cable suitable for the power input of your charger (see

Technical Data). The minimum conductor size is1.5 mm

2

; the maximum

length is30m.

When using a cable reel, always unwind the cablecompletely.

Package Contents

The package contains:

1 Rotary hammer (D25501, D25601, D25602, D25603)

or

1 Chipping hammer (D25820, D25831)

1 Side handle

1 Kitbox (K-models only)

1 Instruction manual

• Check for damage to the tool, parts or accessories which may have

occurred duringtransport.

• Take the time to thoroughly read and understand this manual prior

tooperation.

Markings on Tool

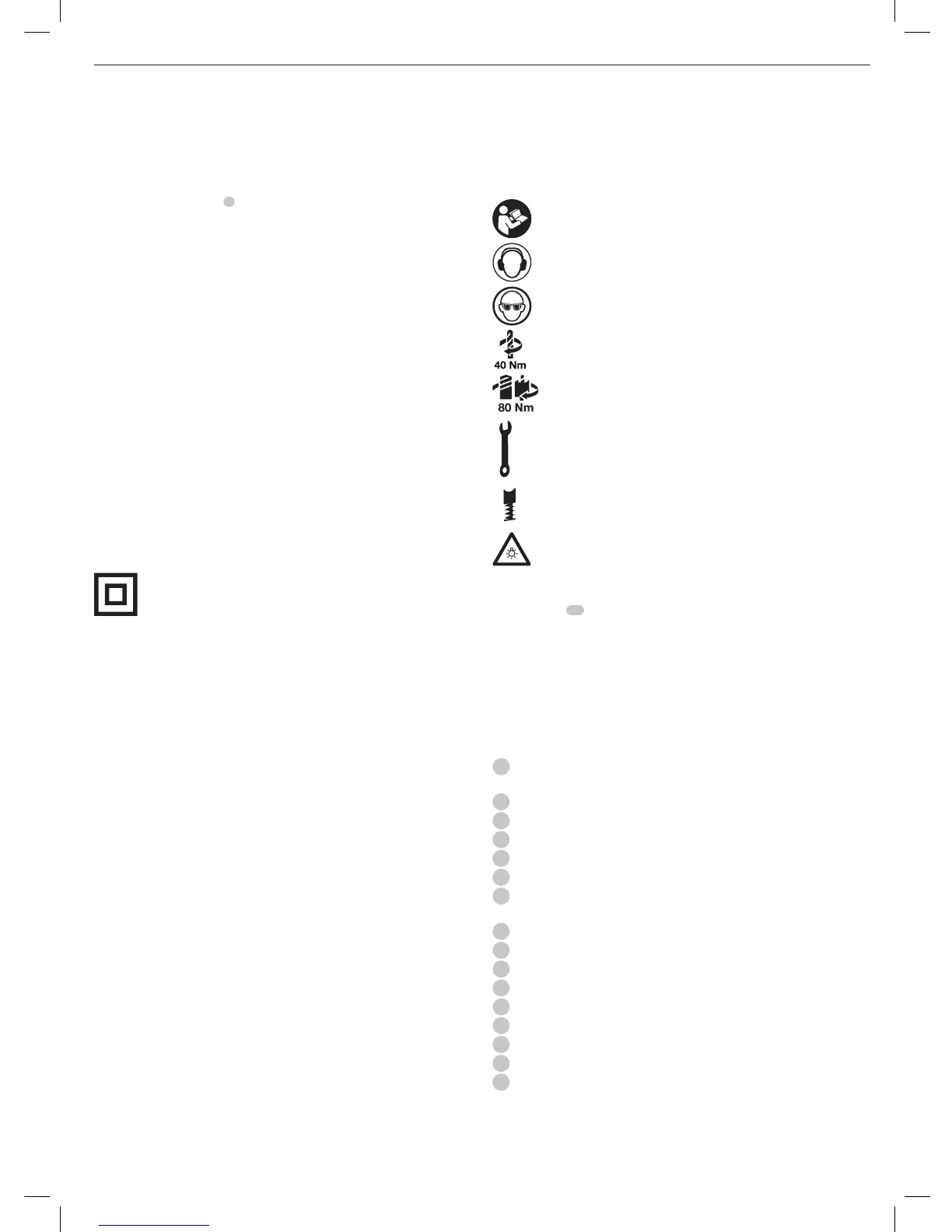

The following pictograms are shown on the tool:

Read instruction manual beforeuse.

Wear earprotection.

Wear eyeprotection.

Clutch Setting 40Nm is designed for most drillingapplications.

Clutch Setting 80Nm is designed for higher

torqueapplications.

Red service indicatorLED. For detailed description see under

Service Indicator LED's.

Yellow service indicatorLED. For detailed description see under

Service Indicator LED's.

Visibleradiation. Do not stare intolight.

Date Code Position (Fig. A)

The date code

23

, which also includes the year of manufacture, is printed

into thehousing.

Example:

2016 XX XX

Year of Manufacture

Description (Fig. A, B)

WARNING: Never modify the power tool or any part ofit. Damage or

personal injury couldresult.

1

Trigger switch (D25501, D25601, D25602, D25603)

On/off rocker switch (D25820, D25831)

2

Lock-on slider (D25601, D25602, D25603)

3

Side handle

4

Main handle

5

Active vibration control (D25601, D25602, D25603, D25831)

6

Mode selector switch

7

Electronic speed and impact control dial (D25601, D25602, D25603,

D25831)

8

Clamp wheel

9

Side handle clamp

10

Steel ring

11

Bush

12

Tool holder

13

Locking sleeve

14

Pin

15

Collar

16

Side handle knob

Intended Use

The D25501, D25601, D25602, D25603 rotary hammers have been designed

for professional rotary drilling and chippingapplications.

Loading...

Loading...