7

ENGLISH

Read instruction manual beforeuse.

Wear earprotection.

Wear eyeprotection.

Borediameter.

Date Code Position (Fig. A)

The date code

18

, which also includes the year of manufacture,

is printed into thehousing.

Example:

2018 XX XX

Year of Manufacture

Description (Fig. A, E)

WARNING: Never modify the power tool or any part of it.

Damage or personal injury couldresult.

1

Lock pin

2

Spark deflector screw

3

Spark deflector

4

Base

5

Fence

6

Vise

7

8mm Hex key

8

Crank

9

Vise lever

10

Wheel

11

Guard

12

Spindle lock

13

Fence bolts

14

Trigger switch

15

Padlock hole

16

Mounting holes

17

Operating handle

18

Date code

Intended Use

Your D28730 chop saw has been designed for the cutting of

variously shaped steelmaterials.

DO NOT use under wet conditions or in the presence of

flammable liquids orgases.

The D28730 chop saw is a professional powertool.

DO NOT let children come into contact with the tool.

Supervision is required when inexperienced operators use

thistool.

• This product is not intended for use by persons (including

children) suffering from diminished physical, sensory or

mental abilities; lack of experience, knowledge or skills

unless they are supervised by a person responsible for their

safety. Children should never be left alone with thisproduct.

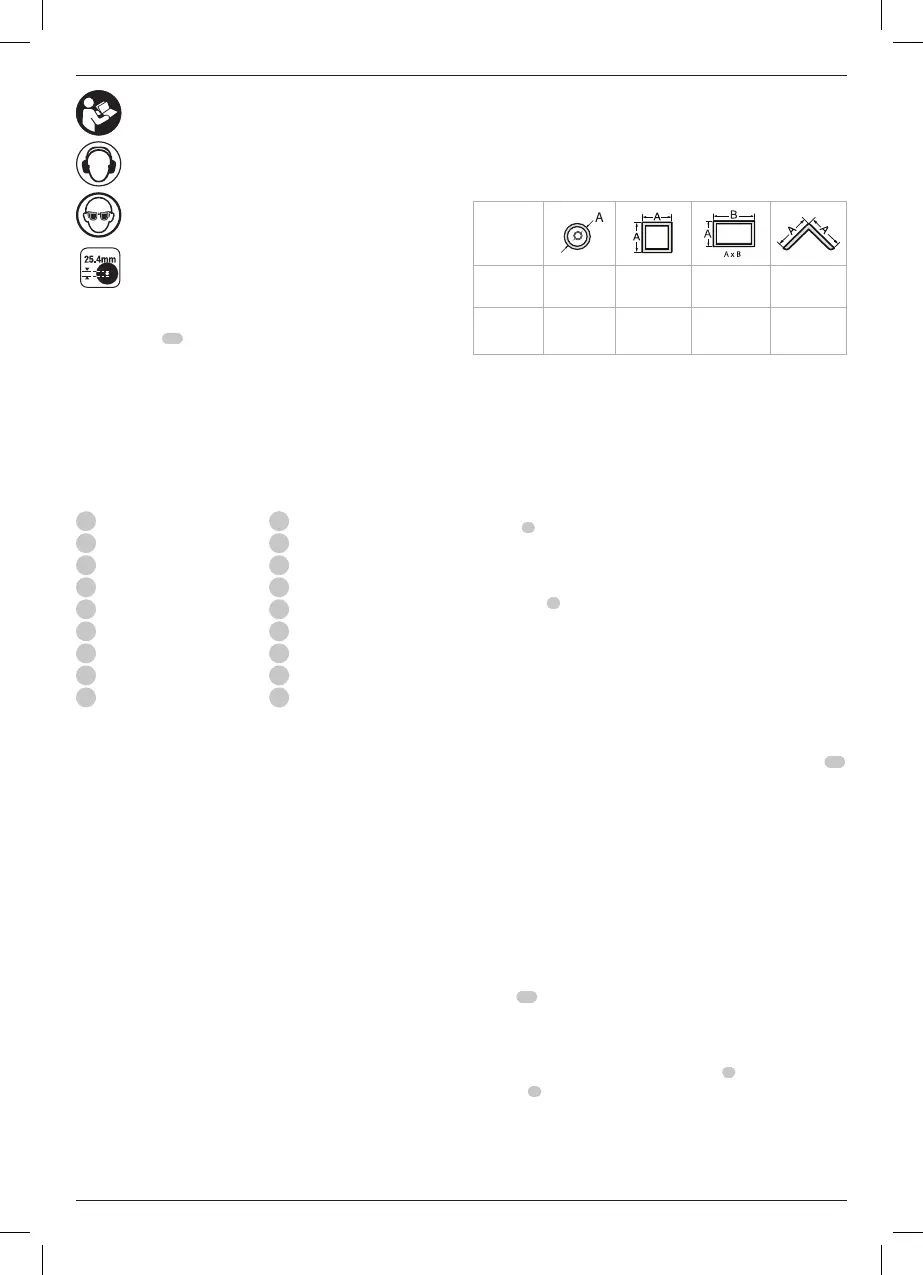

Cutting Capacity

The wide vise opening and high pivot point provide cutting

capacity for many large pieces. Use the cutting capacity chart to

determine total maximum size of cuts that can be made with a

newwheel.

CAUTION: CERTAIN LARGE, CIRCULAR OR

IRREGULARLY SHAPED OBJECTS MAY REQUIRE

ADDITIONAL HOLDING MEANS IF THEY CANNOT BE

HELD SECURELY INVISE.

CAUTION: DO NOT CUT MAGNESIUM WITH

THISTOOL.

Maximum Cutting Capacity

NOTE: Capacity shown on chart assumes no wheel wear and

optimum fenceposition.

Workpiece

Shape

90° Cutting angle A = 130 mm A = 120 mm 115 mm x 130 mm A = 135 mm

45° Cutting angle A = 115 mm A = 102 mm 110 mm x 102 mm A = 110 mm

OPERATION

Instructions for Use

WARNING: Always observe the safety instructions and

applicableregulations.

To Carry (Fig. A)

Fold down unit to position where you can carry the saw. Push in

lock pin

1

to lock armdown.

Unlocking (Fig. A)

To unlock tool and raise head, depress motor arm slightly and

pull lock pin

1

out. Motor arm will then pivotupward.

Mounting (Fig. D, F)

CAUTION: Tool must be supported on stable, level,

non-skid surface to prevent unexpected movement

whenoperating.

1. Drill holes through the work surface that align the base of

the chopsaw.

2. Insert two M10 bolts down through the mounting holes

16

in the base and through holes in mounting surface. The

approximate length of the screws should be the thickness of

the mounting surface plus 102mm.

Proper Hand Position (Fig. A)

WARNING: To reduce the risk of serious personal injury,

ALWAYS use proper hand position as shown.

WARNING: To reduce the risk of serious personal

injury, ALWAYS hold securely in anticipation of a

suddenreaction.

Proper hand position requires one hand on the operating

handle

17

, with the other hand guiding theworkpiece.

Spark Deflector Adjustment (Fig. A)

To best deflect sparks away from surrounding persons and

materials, loosen the spark deflector screw

2

, adjust the spark

deflector

3

and then retighten screw. Do not allow cordset to

come into contact with deflector or sparks as damage to cordset

mayoccur.

Loading...

Loading...