IF 1767 • 09/15 Copyright

©

2015, Eaton’s Crouse-Hinds Division Page 3

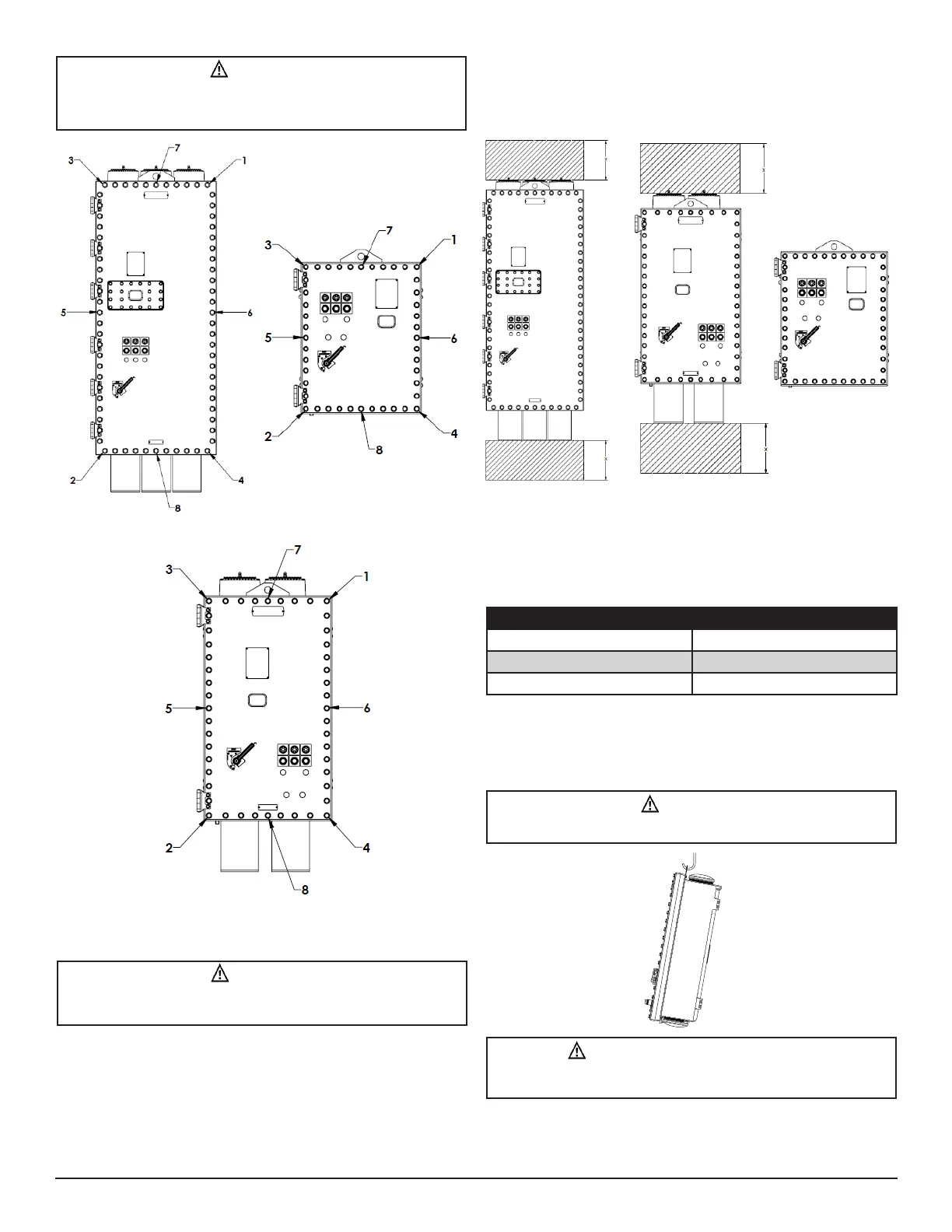

2. MECHANICAL INSTALLATION

2.1 AIRFLOW PROVISIONS - INSTALLATION

DRAWING

It is imperative that the enclosure be well ventilated to ensure reliable

performance. Adequate space around the intake and exhaust of the

enclosure MUST be accommodated. Eaton’s Crouse-Hinds Division

recommends ‘x’ be a minimum of 12 inches (0.3 meters).

2.2 WEIGHTS

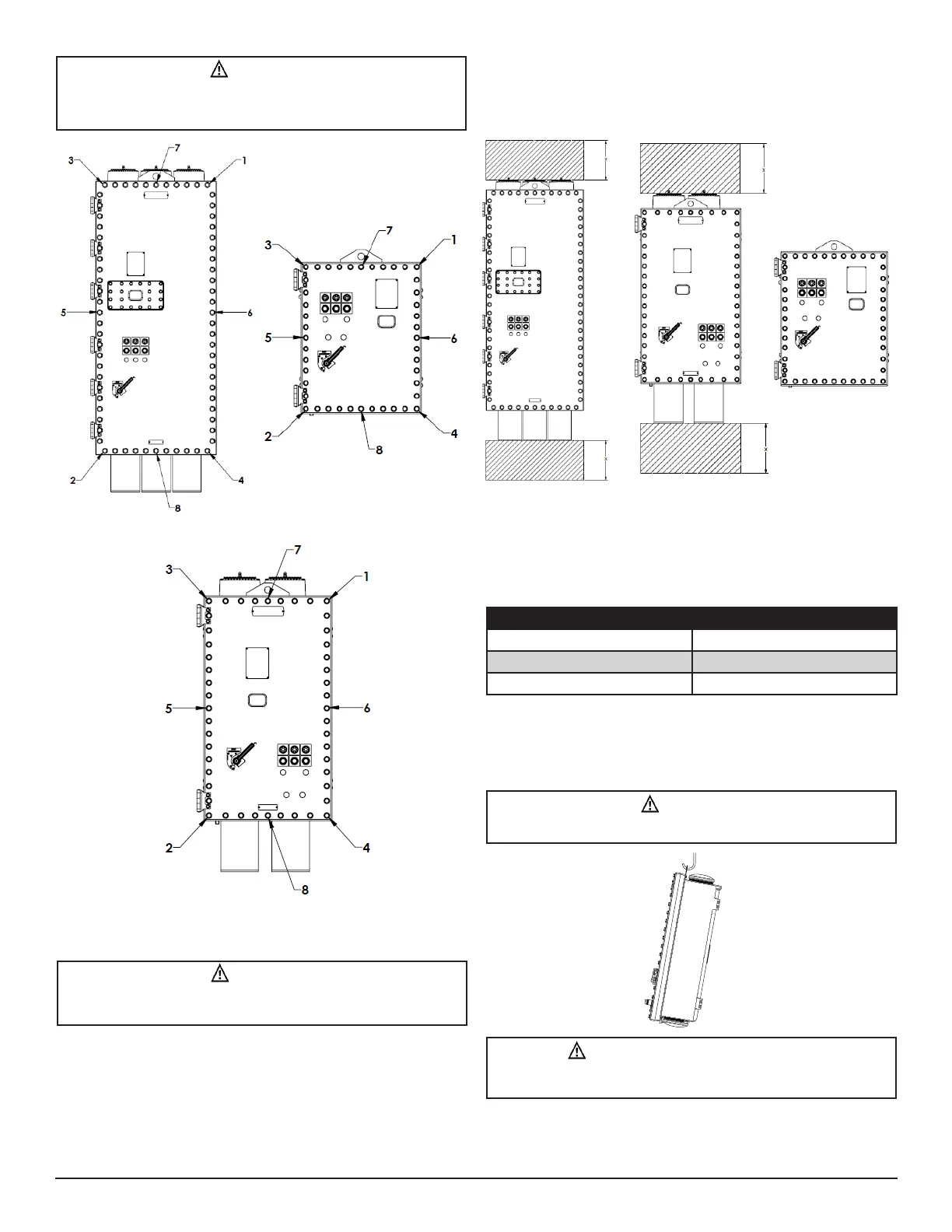

2.3 LIFTING

1. Remove top and sides from shipping crate.

2. Remove lag bolts from enclosure mounting feet

3. Use the dedicated lifting eye to mount enclosure on suitable

mounting surface. Select a mounting location that will provide

suitable strength and rigidity for supporting the enclosure and all

components.

Figure 1

Enclosure Weight (Approx.)

Size 1 (1-5 HP) 350

Size 2 (7-30 HP) 550

Size 3 (40-100 HP) 1200

CAUTION: UNBALANCED LOAD

To avoid personnel injury, utilize the dedicated lifting eye and handle

appropriately to ensure safe installation.

WARNING

To avoid cooling system malfunction and personnel injury, be sure

to torque the first eight (8) cover screws sequentially per Figure 1

before torquing the remaining screws.

WARNING

To avoid personnel injury and property damage, DO NOT remove or

modify the control pad viewing window.

CAUTION

Do not attach shrouds or pre-filters until after enclosure is mounted.

Loading...

Loading...