Maintenance

Periodic inspection

1. External: Periodically check the condition of the paint

and finish, especially when the transformer is exposed

to inclement atmospheric conditions. If weathering

takes place, clean the tank thoroughly, wipe off any

insulating liquid that might have been spilled on the

surface and repaint with a factory approved paint.

Occasionally, inspect and tighten all bolted joints and

check for leaks.

2. Regularly inspect all gauges. The liquid level must

remain normal, considering the temperature effect.

Refill when samples have been taken. Prolonged

periods of zero pressure could indicate a gas leak and

should be checked out. The liquid temperature should

not rise higher than the design value on the nameplate,

plus ambient temperature.

3. Liquid samples should be taken periodically and

analyzed as indicated under "Sampling". It is recom-

mended that you keep a log of the test values to

determine when reconditioning or replenishing service

is required.

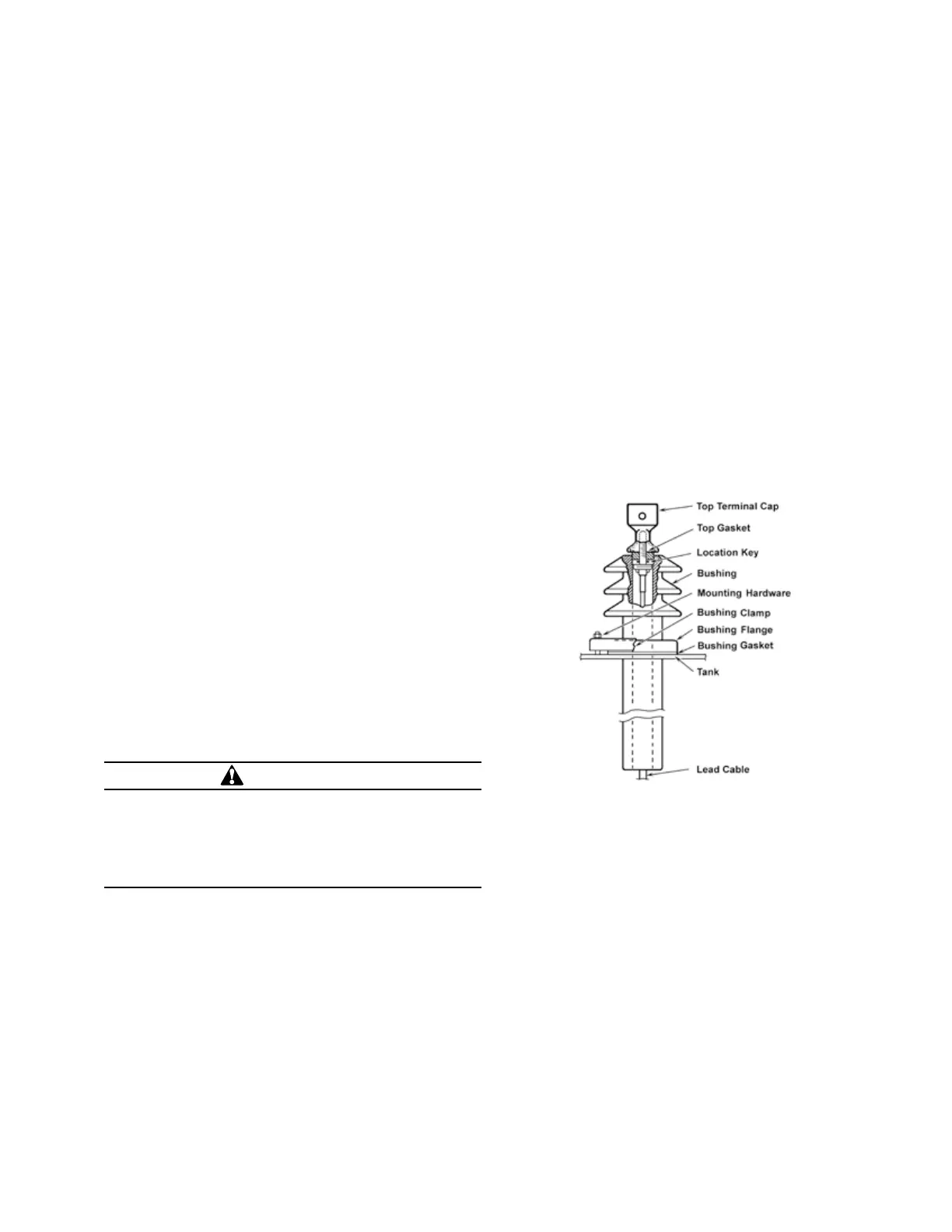

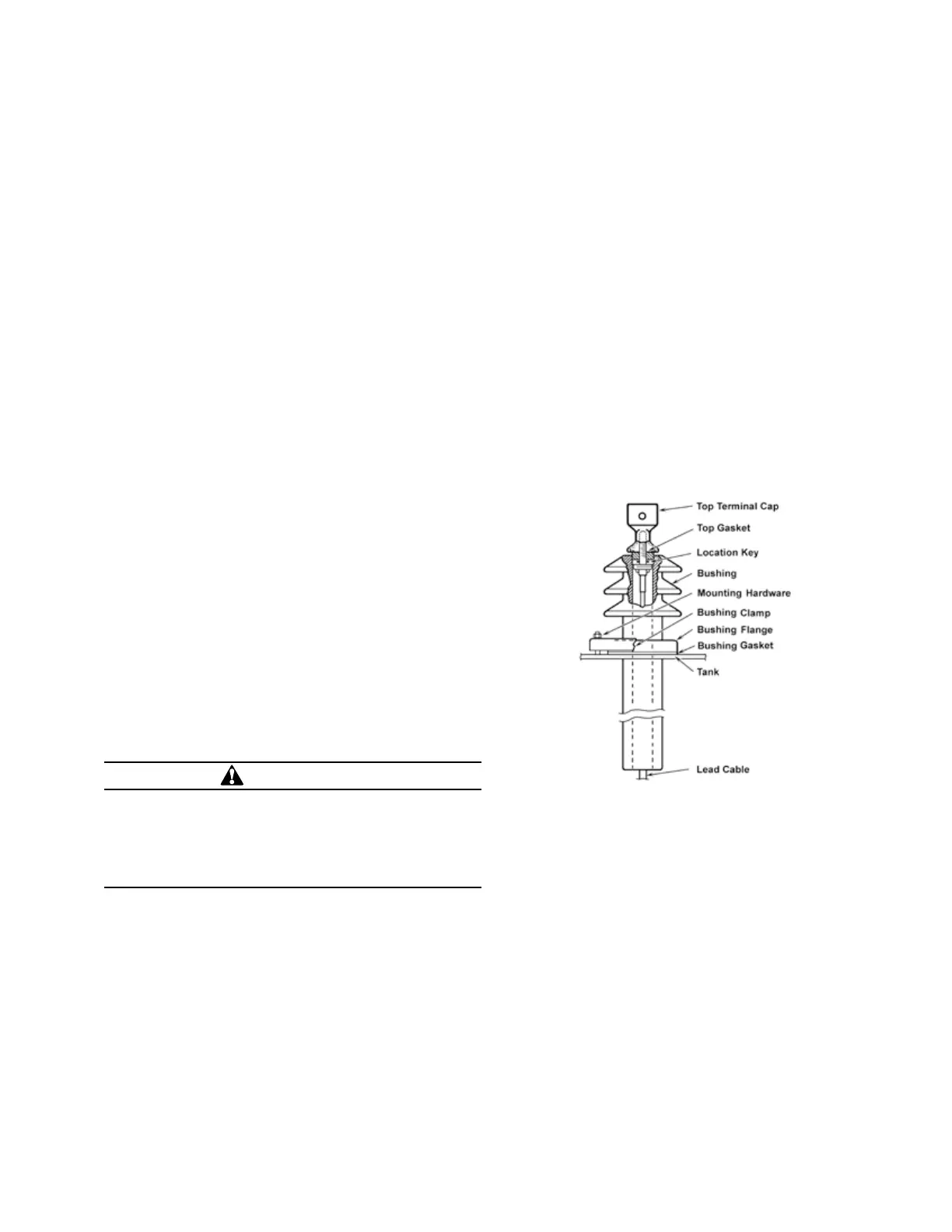

Removing and replacing bushings

Bushing construction falls into two general categories:

"draw lead" type as represented by Figure 12 and bottom

connected types with a fixed center stud or internal spade

as represented by Figure 13.

The method for removing bushings will differ depending

upon the type of construction. The two methods are dealt

with separately in the written material that follows.

Before any work commences, standard safety precautions

must be observed.

WARNING

Before working with bushings, make sure that the

transformer is de-energized and that all circuits to

and from the transformer are grounded in order to

discharge any stored energy and prevent accidental

re-energization. Failure to do so may result in death,

severe personal injury and equipment damage.

Additional precautions include the following:

•

Lock in the “open” position disconnect switches in the

supply lines to and from the transformer.

•

If the transformer is under vacuum or pressure, bring the

tank to ambient pressure.

•

If the bushing to be removed is below the liquid level,

lower the level sufficiently to prevent fluid loss.

•

To protect from the atmosphere and contaminants, store

in clean, dry, sealed containers any removed liquid that

will be returned to the transformer.

Removing and replacing draw lead type bushings

Removing

1. Unscrew and remove the top terminal cap, exposing

the threaded stud end of the draw lead cable. In some

cases, the threaded stud will be held by a pin that must

also be removed.

2. Fasten a pull wire, cord or rod to the stud in order to

guide the lead through the bushing’s bore and prevent

it from falling into the opening when the bushing is

removed. (In some cases, the lead will be of sufficient

thickness to be self-supporting; if so, this part of the

procedure can be omitted).

3. Remove the bushing mounting clamp nuts at the tank

to release the mounting clamp plate and free the

bushing for removal.

4. Remove the bushing, guiding the draw lead conductor

and terminal stud through the base of the bushing.

Figure 11. Draw lead type bushing.

11SubStation tranSformer inStallation and partS replacement information MN202002EN JUNE 2016

Loading...

Loading...