Preventative maintenance instructions

If any issues are found regarding the below, contact PS-WarrantyServices@

Eaton.com for assistance on transformers under warranty. Additionally, these

reports must be available upon request to maintain warranty period.

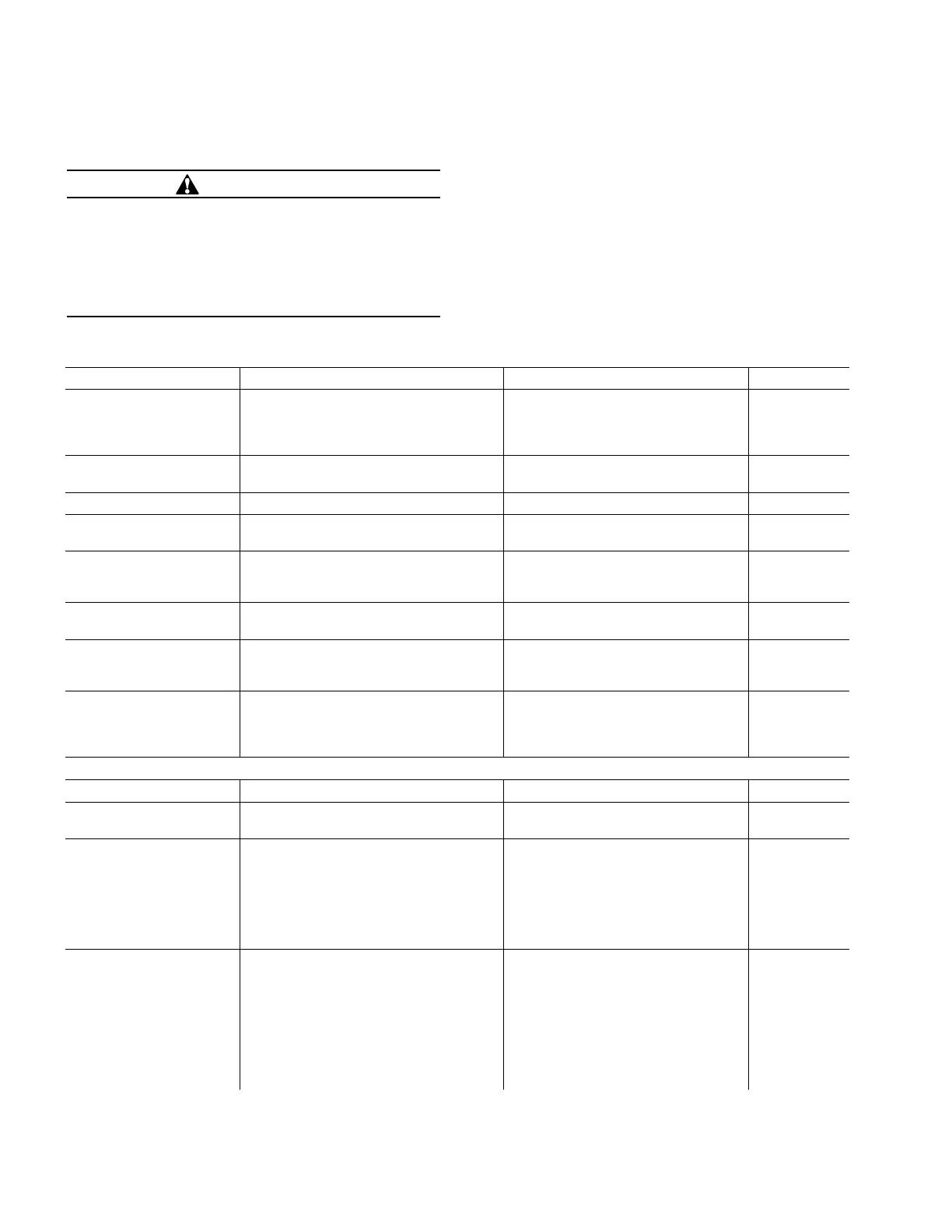

Transformer Exterior Maintenance

Items to Inspect Points to be Checked Remedial Action Frequency

Exterior Surfaces Inspect for evidence of tampering, battered metal,

gouges, etc. Check for any damage that would

allow the entrance of wires or other metallic

devices.

Any such damage should be repaired

immediately.

Annual

Paint or Protective Coatings Inspect for scratches or weathering. Any such damage should be touched up

immediately.

Annual

Tank Leaks Check tank exterior for signs of a leak. Any such leaks should be repaired immediately. Annual

General Location Check the area around the transformer for stored

tools, materials, equipment or debris.

Anything on or against the transformer should

be removed.

Annual

General Location Walk completely around unit and listen for

abnormal noises; should be a steady hum without

intermittent rattling

Any such abnormal noises should be reported

and investigated.

Annual

Pad Verify that pad has not tilted resulting in a

transformer that is more than 5° from horizontal.

If pad support is compromised or out of level

greater than 5°, repair it immediately.

Annual

Nameplates Abnormal or unexpected fading of nameplates or

decals.

Contact your Eaton representative for

replacement nameplates and decals as

necessary.

Annual

Unusual Odors Smells of fluid or burning. This could be indicative

of an unseen leak under the base. Also, inspect the

concrete around the perimeter of the transformer

base for oil spotting.

Any such abnormal odors should be reported

and investigated.

Annual

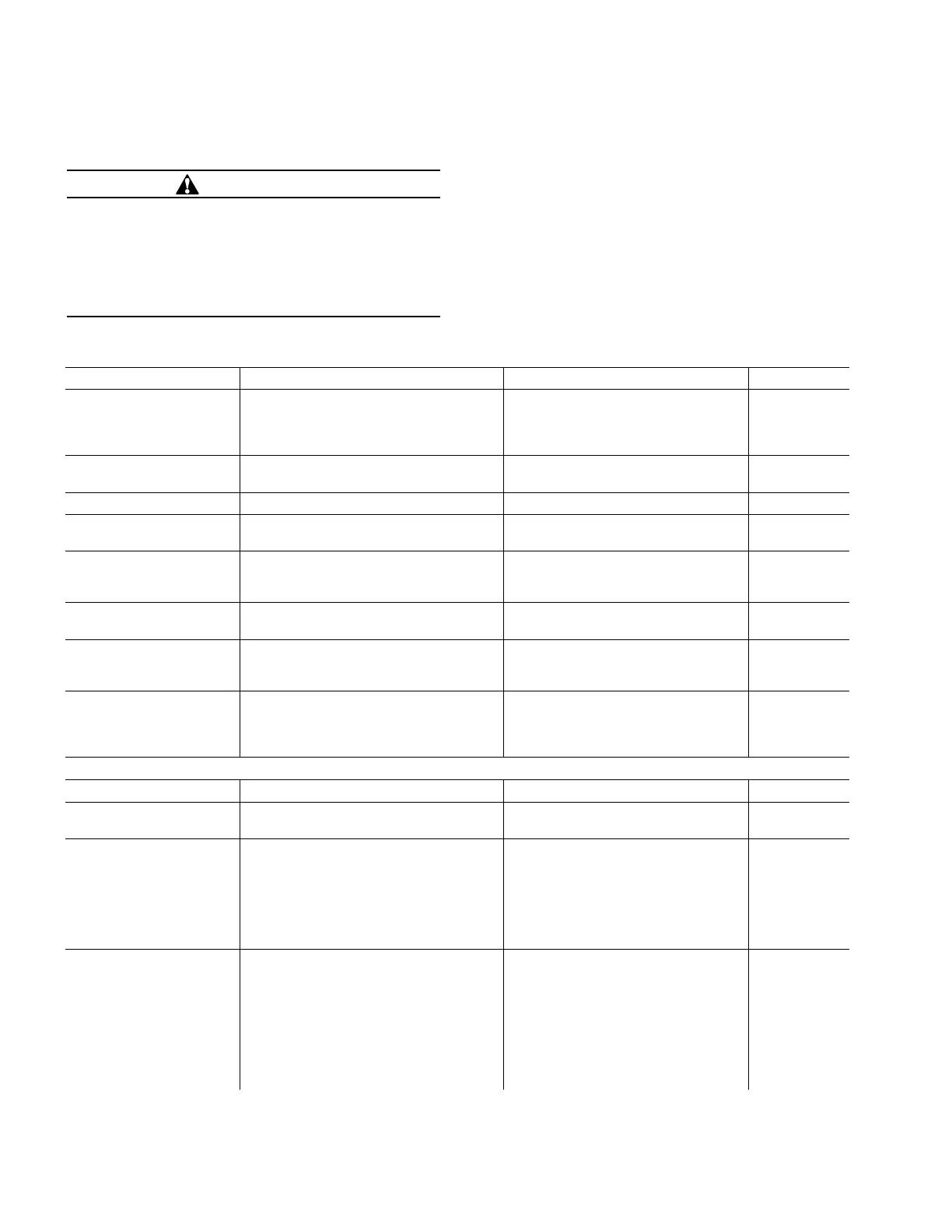

Cabinet Interior Maintenance

Items to Inspect Points to be checked Remedial Action Frequency

Gauges and Controls Check for proper operation. Repair or replace damaged or defective

equipment.

Annual

Equipment Leaks Inspect drain cocks, plugs, fuse mountings, and

switches. Look for evidence of insulating liquid

seepage around tank-wall gaskets, seals, etc.

Repair as required. Replacement of gaskets or

seals in the tank wall may require that the tank

be opened and the insulating liquid lowered

to the appropriate level. For instruction on

opening the tank and for draining and replacing

the insulating liquid, refer to the Insulating

Liquid Maintenance section.

Annual

Tank Pressure Check that pressure/vacuum gauge does not

remain at zero for an extended period of time. It

is preferable that a given unit not cycle between

negative and positive pressures on a daily basis.

Commissioning pressures have been documented

in a separate paper based on the top fluid

temperature. Any observed readings lower than -2

psig or greater than +7 psig indicate a condition

that can and should be corrected.

If the pressure/vacuum gauge remains at zero

for an extended period of time this may be

evidence of air leakage in and out of the tank.

A leak test should be performed by adding

nitrogen to the airspace and observing for loss

of pressure over an interval of a minimum of

12 hours. If the pressure is lost, locate the leak

and repair immediately.

Annual

WARNING

Hazardous voltage. Can cause severe injury, death, or

damage to equipment. De-energize transformer from

a remote upstream source before opening cabinet

and doing cabinet interior inspection or maintenance.

Check that all transformer terminals and bushings have

zero voltage. Ground transformer following industry

accepted safe grounding practices.

16 SubStation tranSformer inStallation and partS replacement information MN202002EN JUNE 2016

Loading...

Loading...