5 Commissioning / operation

5.1 Start-up

Personnel:

n

Operator

n

Specialist

Protective equipment:

n

Protective eyewear

n

Chemical-resistant protective gloves

n

Safety shoes

NOTICE!

Prior to initial operation, check the resistance of the O-rings to the chemicals to

be conveyed:

– EPDM for alkaline

–

FKM HF for acidic

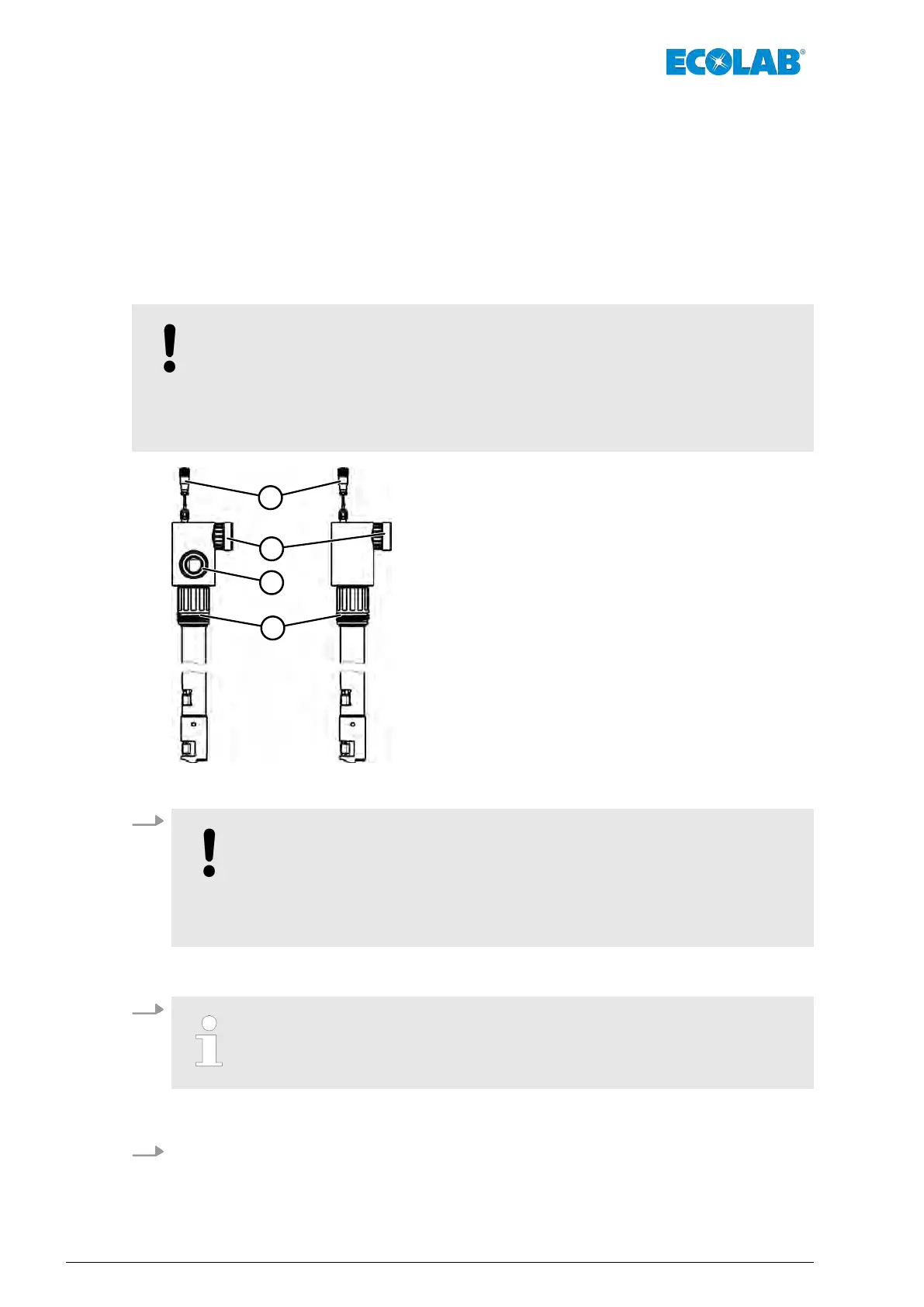

Fig. 3: Putting the suction lance into operation

1 Empty signal input connector

2 Suction connection

3 Return connection

4 Barrel screw joint

1.

NOTICE!

– Only hand-tighten union nuts on the connectors and screwed unions

on containers. Do not use any tools.

– For suction lances with a return connection, be sure not to confuse the

suction and return connection.

Ä

Chapter 4 ‘Structure’ on page 19

Install a connector appropriate for the suction connection on the pump to the 2"

thread on the suction connection.

2.

If a product return is present, use the suction lance 250055 or 250055.

If a product return is present, fit this to the 2" thread of the return connection using a

suitable connector.

3. Connect the empty signal reserve contact to the empty signal input connector.

Commissioning / operation

20Rev. 1-10.2021

Loading...

Loading...