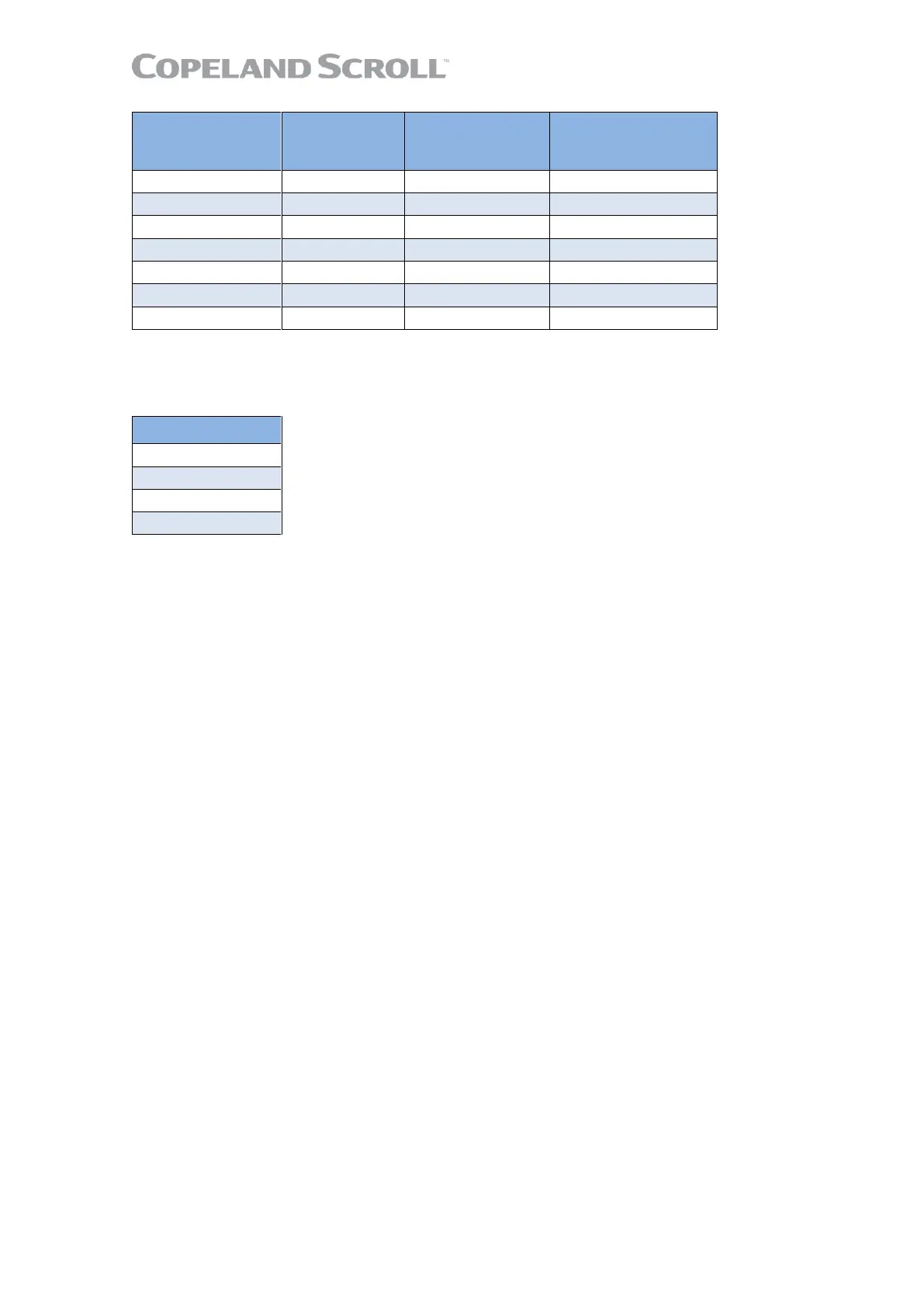

Table 2: Matched pairs ED3 with YHV*2P

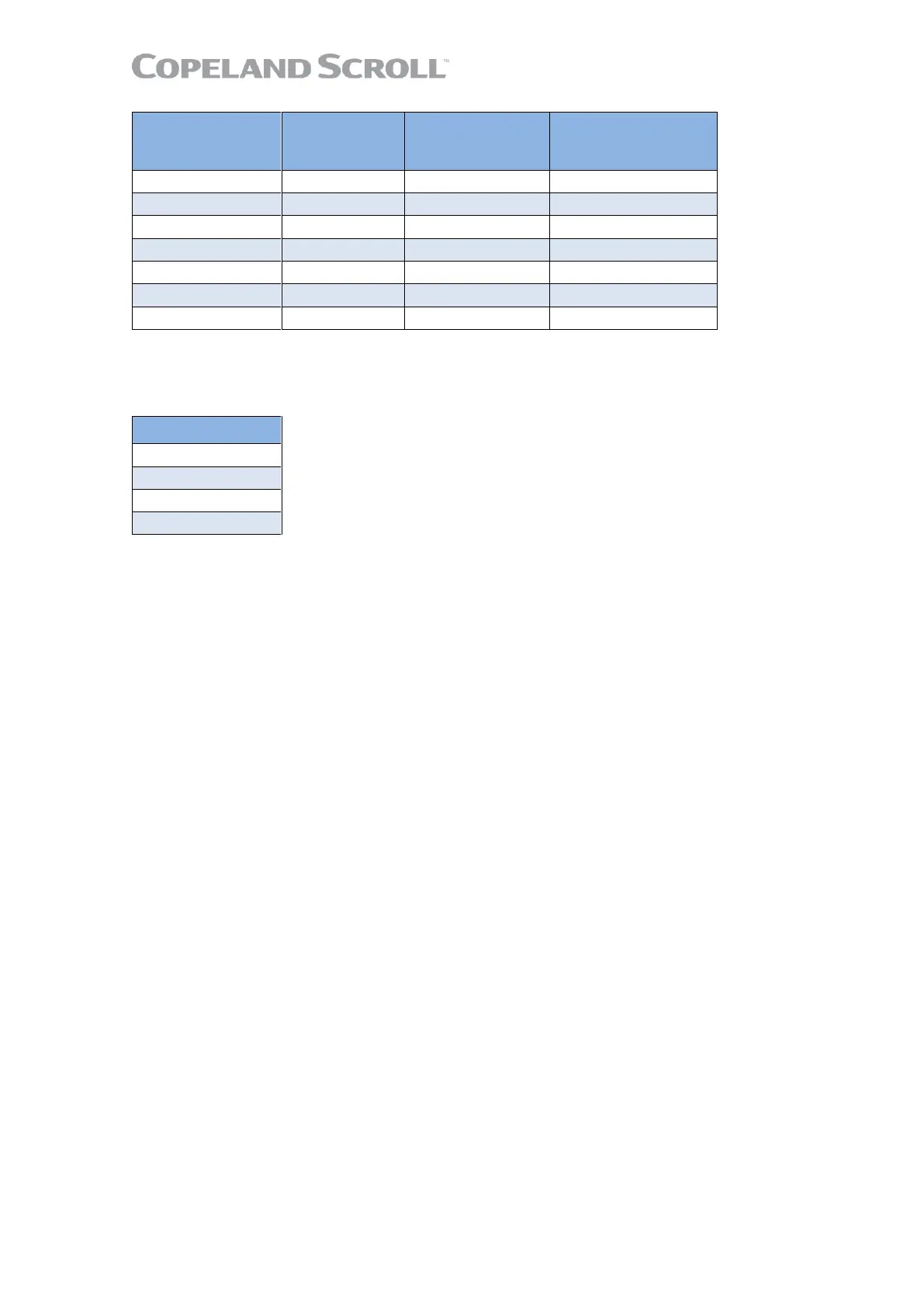

The YHV*2P compressors with protection code "X" (see chapter 2.3) listed in Table 3 are sold as

unprotected compressors. They are dedicated for use with a third-party drive. The motor protection

is under the responsibility of the system manufacturer/installer.

Table 3: Unprotected YHV*2P compressors

A third-party control system must include discharge temperature

protection, current overload

protection, and a soft

start and stopping routine. Stator heat control is also recommended for optimal

performance and reliability. It should also include the operating map parameters. Contact the

Application Engineering department at Emerson for compressor motor

specifications and speed

adjustment requirements.

It is important to ensure correct wiring at both the

compressor and drive connections prior to

starting the compressor to avoid miswiring or powered reverse situation. Both situations could

potentially cause compressor damage.

NOTE: For the latest list of matched pairs ED3 with YHV*2P please refer to the ED3 User

Manual (June 2019 version) or contact the Application Engineering department at Emerson.

2.2 Variable speed advantages

The variable speed scroll is a key component in the variable capacity system. A variable capacity

system will use less electrical energy by minimizing on-off cyclical losses, maximizing heat

exchanger efficiency by operating at part load during a majority of the total operating hours, and by

operating with reduced airflow rates and blower power.

The variable speed scroll and drive are suitable for a variety of "best-in-class" applications. Both may

be used in other types of applications provided that the envelope and other operating restrictions are

met. The primary benefit of this product is to substantially reduce electrical energy consumption and

associated expenses.

Additionally, a variable speed scroll offers the capability of controlling space and domestic hot water

temperature to ranges exceeding simple on-off control, improving overall comfort levels inside the

building. The onboard electronics embedded in the drive greatly reduce the possibility of operation

outside the designed parameters which in turn increases overall system reliability.

Loading...

Loading...