22

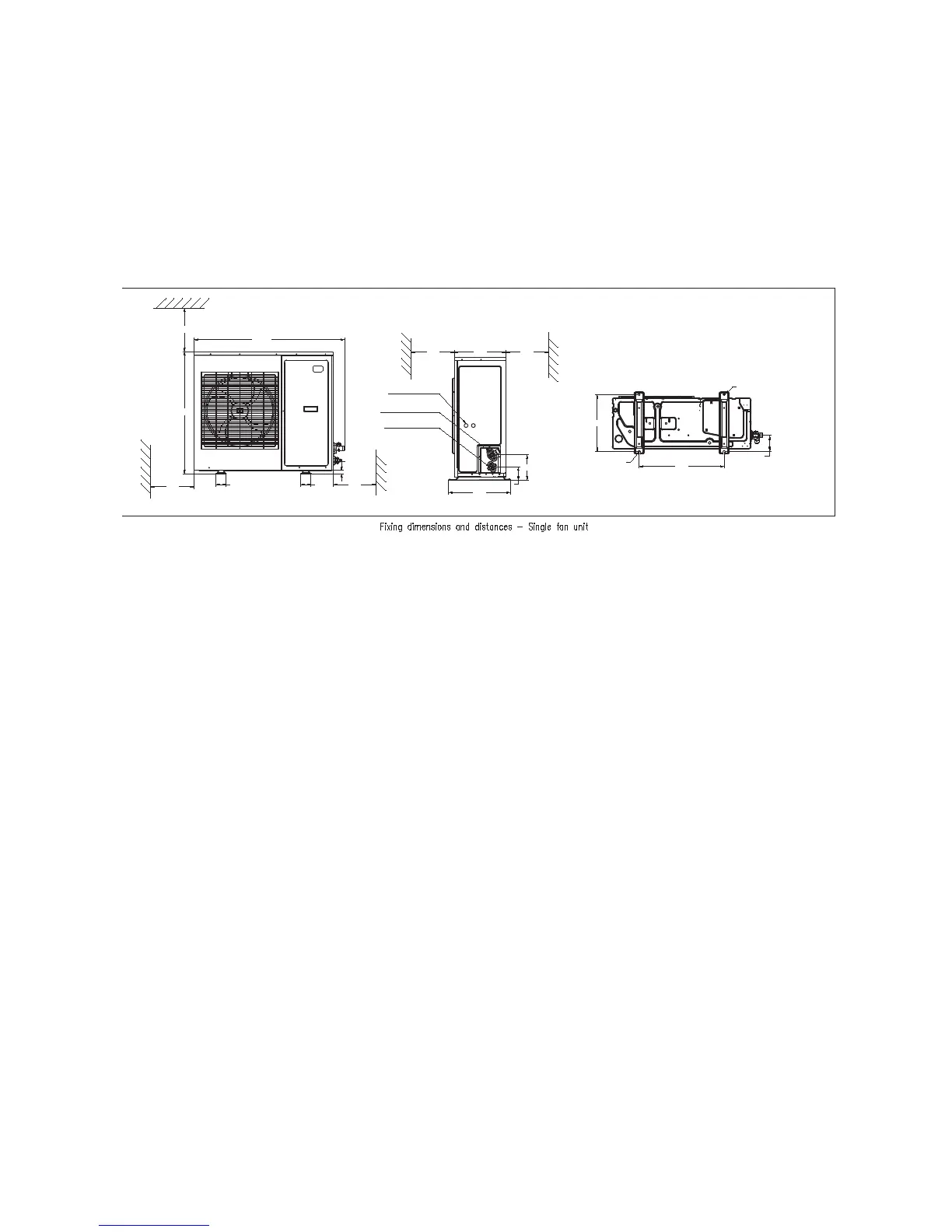

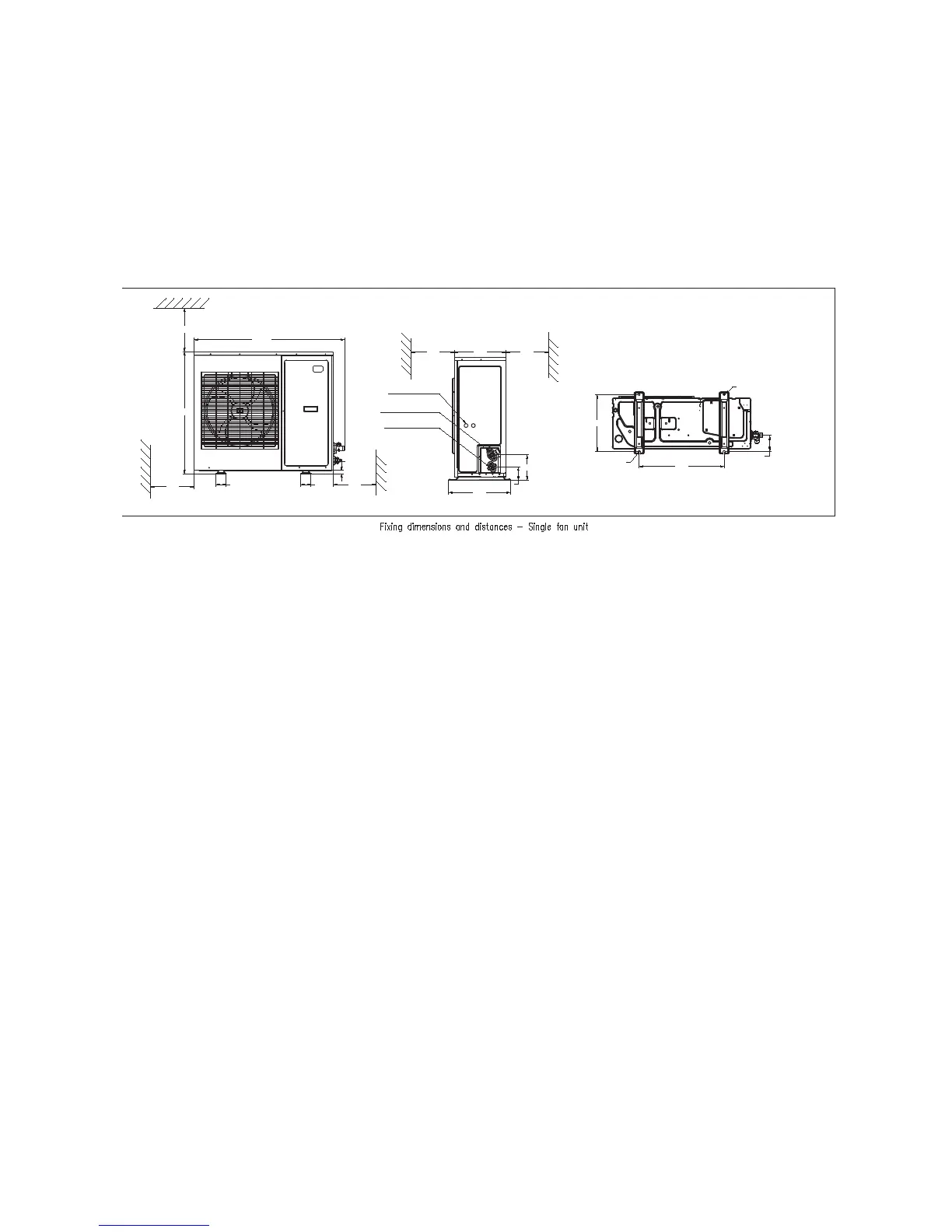

Location and fixing

The unit should always be installed in a location that ensures clean air flow. It is recommended that a clearance of 300 mm from the wall

(or the next unit) be maintained from the unit’s left and rear panels whereas a clearance of 2 meters must be maintained from the unit’s

right, top and front panels (seen facing the front of the unit). Both service access and airflow have been considered in making these

recommendations. Where multiple units are to be installed in the same location, the contractor needs to consider each individual case

carefully. There can be many variations of unit quantities and available space and it is not the intention of this manual to go over these.

Ideally, the unit should be mounted on a solid concrete slab with anti-vibration pads between unit feet and concrete. However the ZX

condensing unit has also been designed for wall mounting on suitable brackets. Wall mounting brackets are not included. Another factor

to consider in finding a good installation site is the direction of the prevailing wind. For example if the air leaving the condenser faces

the prevailing wind, the air flow through the condenser can be impeded, causing high condensing temperatures ultimately resulting in

reducing unit life. A baffle is a remedy for this situation.

Start up and operation

Before commissioning, ensure that all valves on the condensing unit are fully opened.

Vacuuming

The evacuation procedure is based upon achieving an actual system vacuum standard and is not time dependent. Before the installation is

put into commission, it has to be evacuated with a vacuum pump. Proper evacuation reduces residual moisture to 50ppm. The installation of

adequately sized access valves at the furthest point from the compressor in the suction and liquid lines is advisable. To achieve undisturbed

operation, the compressor valves are closed and the system is evacuated down to 0.3 mbar / 0.225 Torr. Pressure must be measured using

a vacuum pressure (Torr) gauge on the access valves and not on the vacuum pump; this serves to avoid incorrect measurements resulting

from the pressure gradient along the connecting lines to the pump.

Charging procedure

Refrigerant charging procedure

The scroll compressor design requires system charging as quickly as possible with liquid refrigerant into the liquid line. This will avoid

running the compressor under conditions where there is insufficient suction gas. Sufficient suction gas is available to cool not only the

motor but also the scrolls. Temperature builds up very quickly in the scrolls if this is not done. Do not charge vapor (gas) refrigerant into the

ZX Scroll unit. The suction service valve must not be fully closed at any time while the compressor is running. To do so would cause damage

to the compressor in the same manner as explained above. This valve is provided for ease of connection and for the fitting of service gauges

without removing the unit panel. It is recommended to charge the ZX unit with refrigerant via its service valves. It is recommended to break

the vacuum in the system with a partial charge of the refrigerant, before starting the system. For charge adjustment, it is recommended to

check the liquid sight glass just before the expansion valve.

Oil charging procedure

Emerson ZX condensing units are supplied only with a compressor oil charge. After commissioning, the oil level should be

checked and topped up if necessary. The oil level should be approximately halfway up the sight glass (ZXL/ZXV/ ZXD units). Oil can be

charged through the Schraeder valve on suction valve.

Loading...

Loading...