Instruction Manual

D100399X012

EW Valve

July 2017

27

3. Place the C‐seal plug seal over the top of the valve plug and press it onto the plug using the installation tool.

Carefully press the C‐seal plug seal onto the plug until the installation tool contacts the horizontal reference surface

of the valve plug (figure 11).

4. Apply a suitable high‐temperature lubricant to the threads on the plug. Then, place the C‐seal retainer onto the

plug and tighten the retainer using an appropriate tool such as a strap wrench.

5. Using an appropriate tool such as a center punch, stake the threads on top of the plug in one place (figure 12) to

secure the C‐seal retainer.

6. Replace the piston ring(s) following instructions in the Trim Replacement section of this manual.

7. Return the seat ring, cage, plug/retainer assembly, and stem to the valve body and completely reassemble the valve

package following the appropriate instructions in the Trim Replacement section of this manual.

CAUTION

To avoid excessive leakage and seat erosion, the valve plug must be initially seated with sufficient force to overcome the

resistance of the C‐seal plug seal and contact the seat ring. You can correctly seat the valve plug by applying the full

actuator load. This force will adequately drive the valve plug to the seat ring, thus giving the C‐seal plug seal a

predetermined permanent set. Once this is done, the plug/retainer assembly, the cage, and the seat ring become a

matched set.

With full actuator force applied and the valve plug fully seated, align the actuator travel indicator scale with the lower end

of valve travel. Refer to the appropriate actuator instruction manual for information on this procedure.

ENVIRO‐SEAL Bellows Seal Bonnet

Replacing a Plain or Extension Bonnet with an ENVIRO‐SEAL Bellows Seal Bonnet

(Stem/Bellows Assembly)

Except where indicated, key numbers in this section are referenced in figure 22 for EWD constructions, figure 22 for

restricted trim detail, figure 23 for EWS constructions, and figure 24 for EWT constructions. Refer to figures 26 and 27

for Cavitrol III, figure 27 for Whisper Trim III, and figure 29 for WhisperFlo constructions.

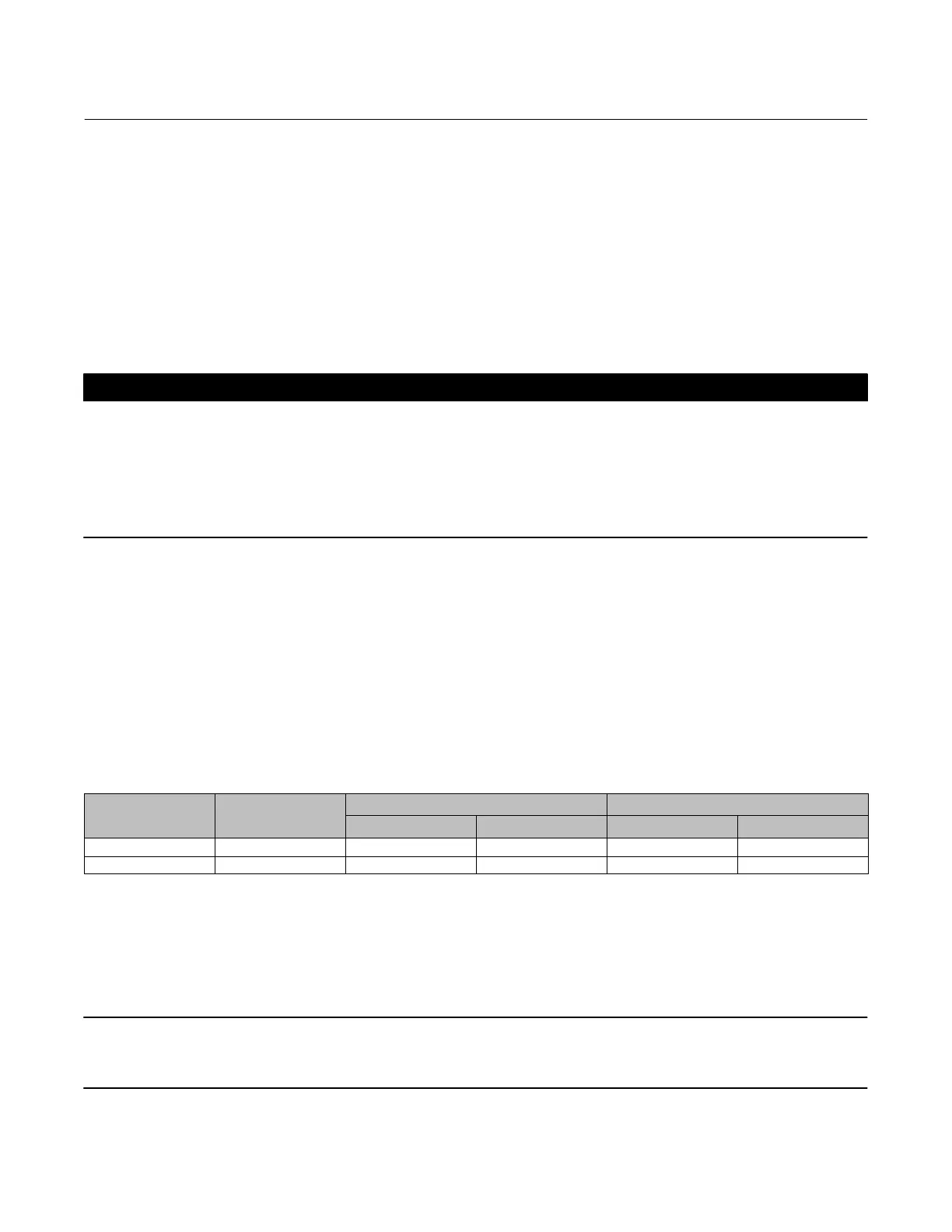

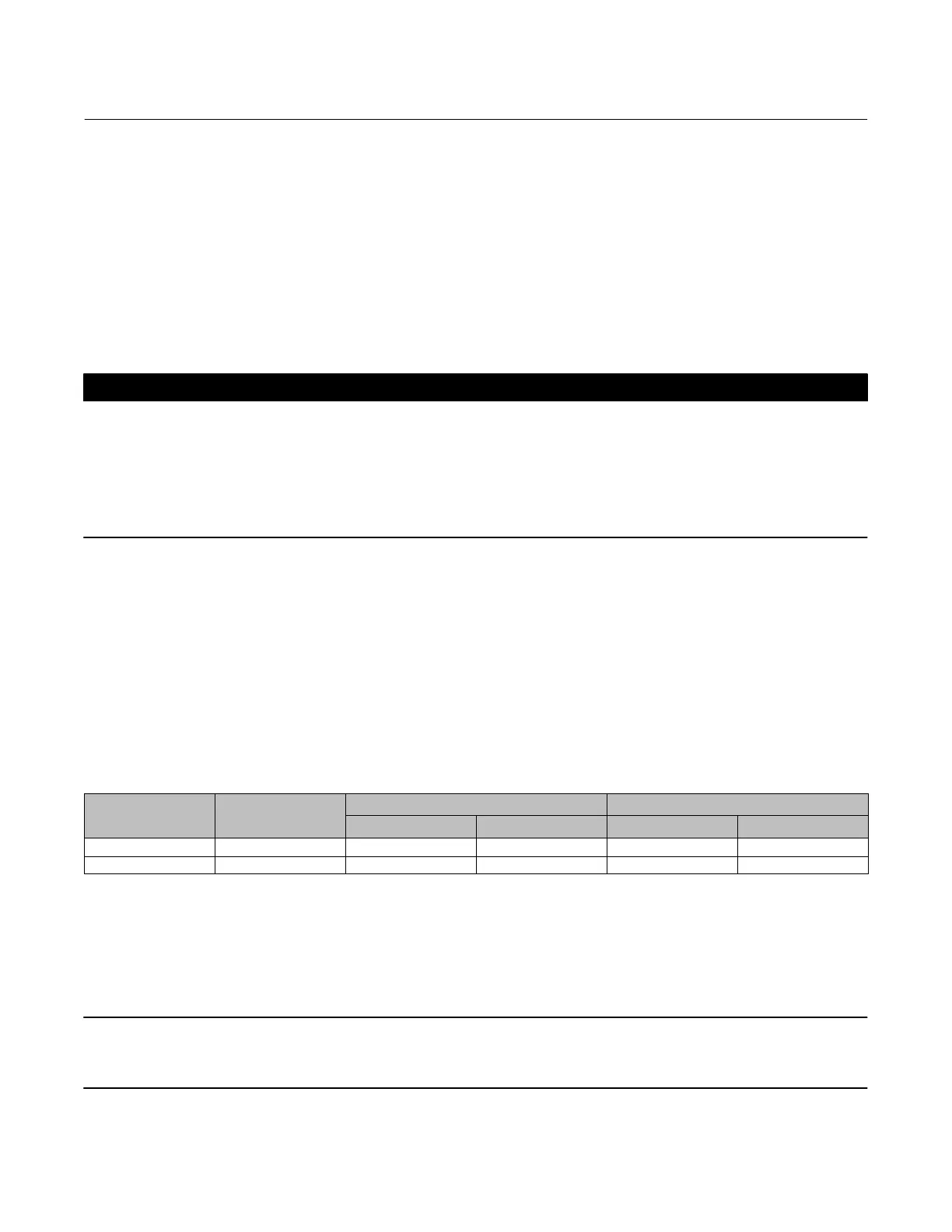

Table 8. Recommended Torque for ENVIRO‐SEAL Bellows Seal Bonnet Packing Flange Nuts

VALVE SIZE,

NPS

VALVE STEM

DIAMETER THROUGH

PACKING

MINIMUM TORQUE MAXIMUM TORQUE

NSm LbfSin NSm LbfSin

4x2 1/2 2 22 4 33

6x4 to 12x8 1 5 44 8 67

1. Remove the actuator and bonnet according to steps 1 through 6 of the Replacing Packing procedure in the

Maintenance section.

2. Lift out the cage.

3. Remove and discard the existing bonnet gasket. Cover the valve body opening to protect sealing surfaces and to

prevent foreign material from entering the valve body cavity.

Note

The ENVIRO‐SEAL stem/bellows assembly for easy-et valves is available only with a threaded and drilled plug/adaptor/stem

connection. The existing valve plug can be reused with the new stem/bellows assembly or a new plug can be installed.

Loading...

Loading...