Do you have a question about the Emerson Fisher EWT and is the answer not in the manual?

| Brand | Emerson |

|---|---|

| Model | Fisher EWT |

| Category | Control Unit |

| Language | English |

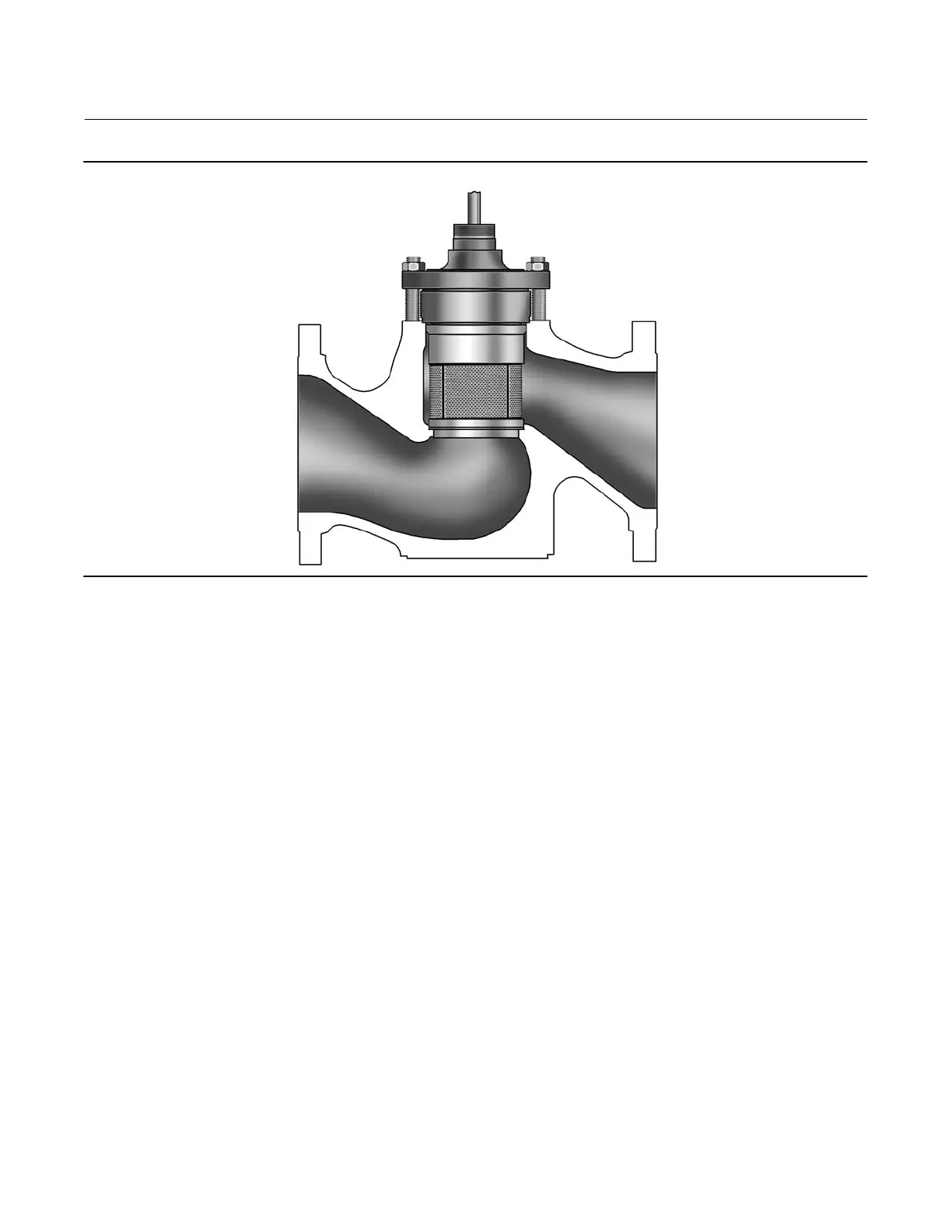

Details installation, maintenance, and parts for Fisher NPS 4x2 through 12x8 EWD, EWS, and EWT valves.

Describes flanged and buttwelding end connection styles for various valve sizes and pressure ratings.

Lists pressure/temperature ratings per ASME B16.34, not exceeding ordered conditions.

Details shutoff classes for C-seal and WhisperFlo trims, referencing tables.

Outlines flow characteristics for standard, Cavitrol, and WhisperFlo cages.

Specifies flow directions for EWS, EWD, and EWT valves with standard cages.

Lists materials like 410 Stainless Steel for WhisperFlo trims.

Provides pressure/temperature range for WhisperFlo trims.

Defines inherent outlet velocity limit for WhisperFlo trim.

Describes EWD valves with metal-to-metal seating for general applications.

Details C-seal trim for EWD valves, achieving high-temperature, Class V shutoff.

Describes EWS valves with metal-to-metal or PTFE seating for better shutoff.

Describes EWT valves with PTFE or metal-to-metal seating for shutoff or high temperatures.

Contact information for educational services and training courses for EW valves.

Safety warning about protective gear and conditions exceeding limits to prevent injury or damage.

Pre-installation check for damage or foreign material in the valve and pipelines.

Guidance on valve assembly orientation and potential wear issues.

Suggestion to use upstream strainers for valves with small flow passages like WhisperFlo.

Caution regarding post-weld heat treatment and its effect on valve parts.

Procedure for connecting leak-off piping or installing a bypass.

Instruction to refer to actuator manual if shipped separately.

Warning about potential component dropping during disassembly/assembly of inverted valves.

Step-by-step instructions for disassembling inverted valve assemblies.

Step-by-step instructions for assembling inverted valve assemblies.

Warning about personal injury/property damage from sudden pressure release during maintenance.

Caution against lubricating graphite packing to avoid slip-stick movement.

Warning against lubricating packing in oxygen service or high temperatures to prevent fire/explosion.

Illustrates PTFE V-ring packing arrangements for single configurations.

Illustrates PTFE V-ring packing arrangements for double configurations.

Refers to specific manuals for ENVIRO-SEAL and HIGH-SEAL packing instructions.

Guidance on checking packing follower for sealing force.

Steps to limit leakage and establish stem seal by tightening packing nuts.

Warning about personal injury/damage from sudden pressure release before maintenance.

Warning on uncontrolled bonnet movement when loosening.

Caution to avoid damage to seating surfaces when lifting bonnet.

Step 5: removing hex nuts and bonnet.

Step 6: removing locknut and separating plug/stem.

Step 7: removing bonnet gasket and covering opening.

Step 8: removing packing parts and cleaning.

Step 9: inspecting stem threads and packing box surfaces.

Step 10: installing new bonnet gasket and assembling valve.

Proper performance of tightening procedures for gasket and bonnet seal.

Warning about using unapproved stud/nut materials causing potential failure.

Step 11: lubricating and tightening bolting to specified torque.

Step 14: tightening packing flange nuts for various packing types.

Warning about personal injury/damage from sudden pressure release before maintenance.

Caution to avoid damaging bellows assembly parts.

Warning about personal injury/damage from valve or packing leakage.

Step 1: removing actuator and bonnet.

Step 6: removing cage/baffle assembly and gaskets.

Step 7: removing seat ring, adapter, disk seat etc.

Step 8: specific steps for TSO trim removal.

Step 9: inspecting parts for wear or damage.

Caution against lapping metal seats on ENVIRO-SEAL bellows seal bonnet assembly.

Procedure for lapping metal seats using a temporary handle.

Caution when replacing piston or seal rings to avoid scratching.

Instructions for installing EWD carbon-filled PTFE piston rings.

Instructions for removing and installing EWT two-piece and spring-loaded seal rings.

Caution against reusing old stems or adaptors with new valve plugs.

Step 1: installing adaptor gasket and seat ring adaptor.

Step 4: sliding valve plug and stem assembly into cage.

Step 5: trim replacement steps for TSO constructions.

Caution to avoid leakage by properly seating valve plug with sufficient force.

Note on additional actuator thrust for C-seal trim.

Caution to protect sealing surfaces during C-seal trim assembly.

Step 3: pressing C-seal plug seal onto valve plug using tool.

Step 5: staking threads to secure C-seal retainer.

Step 8: removing actuator and bonnet.

Caution against removing valve stem unless replacing it.

Step 11: installing new parts and reassembling valve.

Instructions for removing C-seal trim parts from the valve.

Caution to avoid leakage during maintenance of C-seal trim.

Step 3: drilling out staked thread on valve plug.

Step 6: rotating retainer to free it from valve plug.

Step 7: prying C-seal plug seal off the plug.

Step 8: inspecting seating surfaces for wear or damage.

Instruction to lap lower seating surface before installing new C-seal plug seal.

Caution about matching metal removal for C-seal trim to avoid crushing.

Step 1: lubricating C-seal plug seal and valve plug.

Step 2: orienting C-seal plug seal based on flow direction.

Note about using a C-seal installation tool.

Step 5: staking threads to secure C-seal retainer.

Caution to avoid leakage by properly seating valve plug with sufficient force.

Instructions for replacing bonnet with ENVIRO-SEAL assembly.

Step 1: removing actuator and bonnet.

Step 3: removing and discarding bonnet gasket.

Note about ENVIRO-SEAL stem/bellows assembly availability.

Step 4: inspecting existing valve plug for reuse.

Caution against rotating valve stem when installing plug on ENVIRO-SEAL assembly.

Step 6: attaching valve plug to stem of new assembly.

Step 7: completing installation per ENVIRO-SEAL instructions.

Step 1: removing pipe plugs for purging.

Step 3: installing piping for purging or leak testing.

Warning about using unapproved stud/nut materials causing potential failure.

Step 12: lubricating and tightening bonnet stud bolts.

Step 14: installing packing flange.

Step 1: removing actuator and bonnet.

Step 2: lifting cage and removing gaskets.

Caution regarding ENVIRO-SEAL stem/bellows assembly reuse of plug/adaptor.

Step 4: removing and replacing plug/adaptor assembly.

Warning to use only genuine Fisher replacement parts to avoid warranty voidance or damage.

Lists gasket kits by valve size, trim type, and part number.

Lists standard packing repair kits by stem diameter and yoke boss diameter.

Lists retrofit kits for HIGH-SEAL and ENVIRO-SEAL packing conversions.

Lists repair kits for ENVIRO-SEAL packing arrangements.

Note about part numbers and contacting sales for unlisted parts.

Lists bonnet parts with keys, descriptions, and part numbers.

Note on part numbers for standard valves and Whisper Trim I cages.

Actuator group details based on yoke boss size.

Actuator group details based on yoke boss size.

Actuator group details based on yoke boss size.

Actuator group details based on yoke boss size.