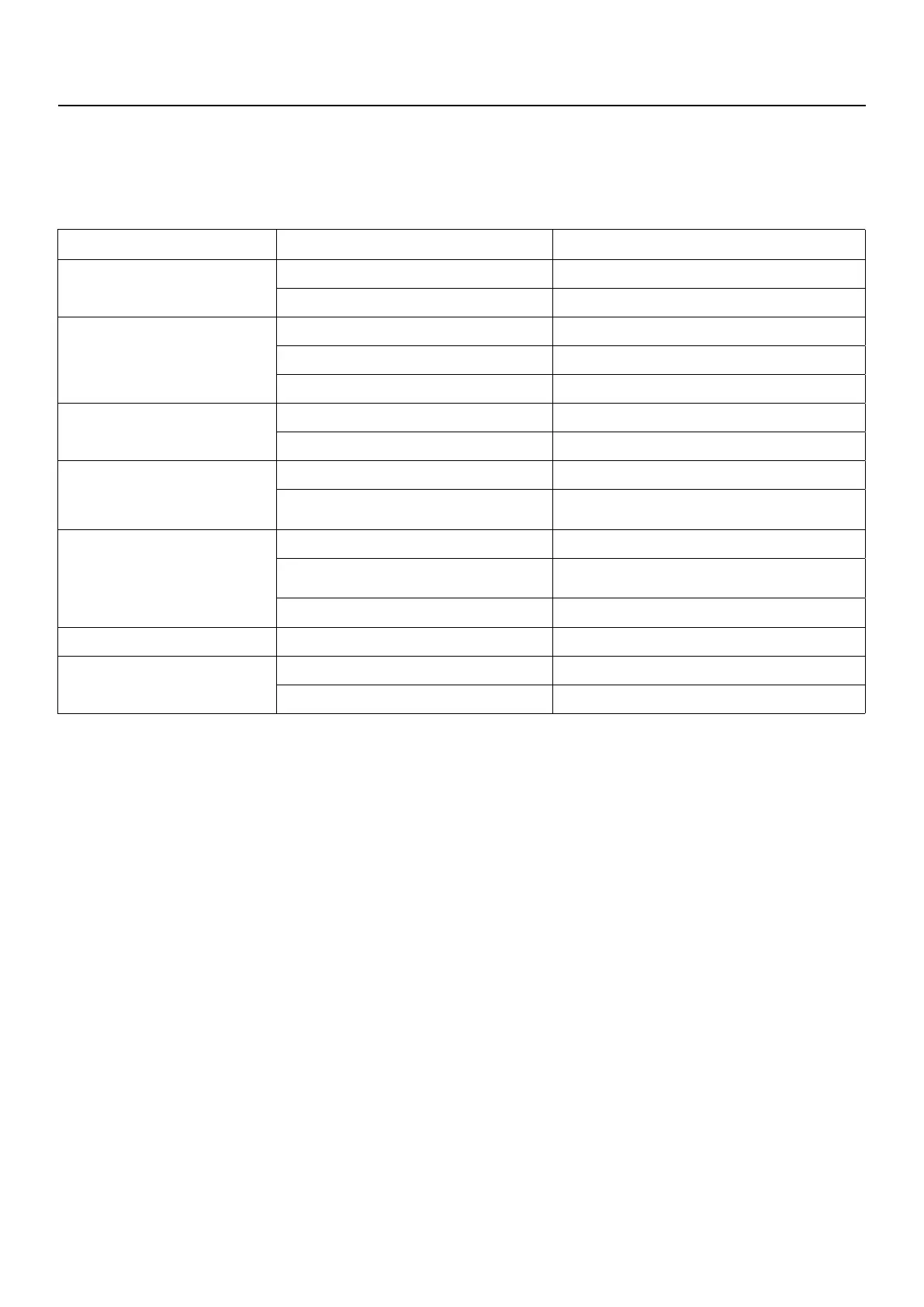

Table 3. Troubleshooting for Type PS/79 and PS/80 Pilots

SYMPTOMS CAUSE ACTIONS

Desired setpoint is not reached

Calibration spring (key 5) is too weak Check the springs catalog and replace it with a stronger one

Leaks from pilot connections Check pilot feed connections and proper gas ow feeding

Outlet pressure drops well below setpoint

Filter (key 61) is clogged preventing proper through-ow of gas Clean or replace it

Pad holder (key 56) is swollen preventing proper feed ow To be replaced

Pad holder (key 34) is swollen preventing proper feed ow To be replaced

Outlet pressure increases over setpoint

Faulty sealing of pad holder (key 56) To be replaced

Faulty sealing of pad holder (key 34) To be replaced

Slow response to changes in gas demand

Insufcient ow rate of valve seat (key 30) Increase ow by means of register/pin screw (key 29)

Overly large calibration jet (key 15)

(only for Types PS/79 and PS/80)

To be replaced with a smaller one

Overly rapid response to changes in gas

demand, i.e. Hunting

Excessive ow rate of valve seat (key 30) Reduce ow by means of a pin screw (key 29)

Calibration jet (key 15) is too small

(only for Types PS/79 and PS/80)

To be replaced with a larger one

Not proper internal parts assembly Check clearance between lever (key 39) and forked stem (key 35)

Gas continually escaping from relief (S) Defective seal of pad (key 21) To be replaced

The outlet pressure is not within the usual values

Diaphragms (key 10) are damaged Replace diaphragms (key 10) that show signs of wear

Upper diaphragm (key 10) is damaged If gas escapes from silencer (key 45), replace upper diaphragm (key 10)

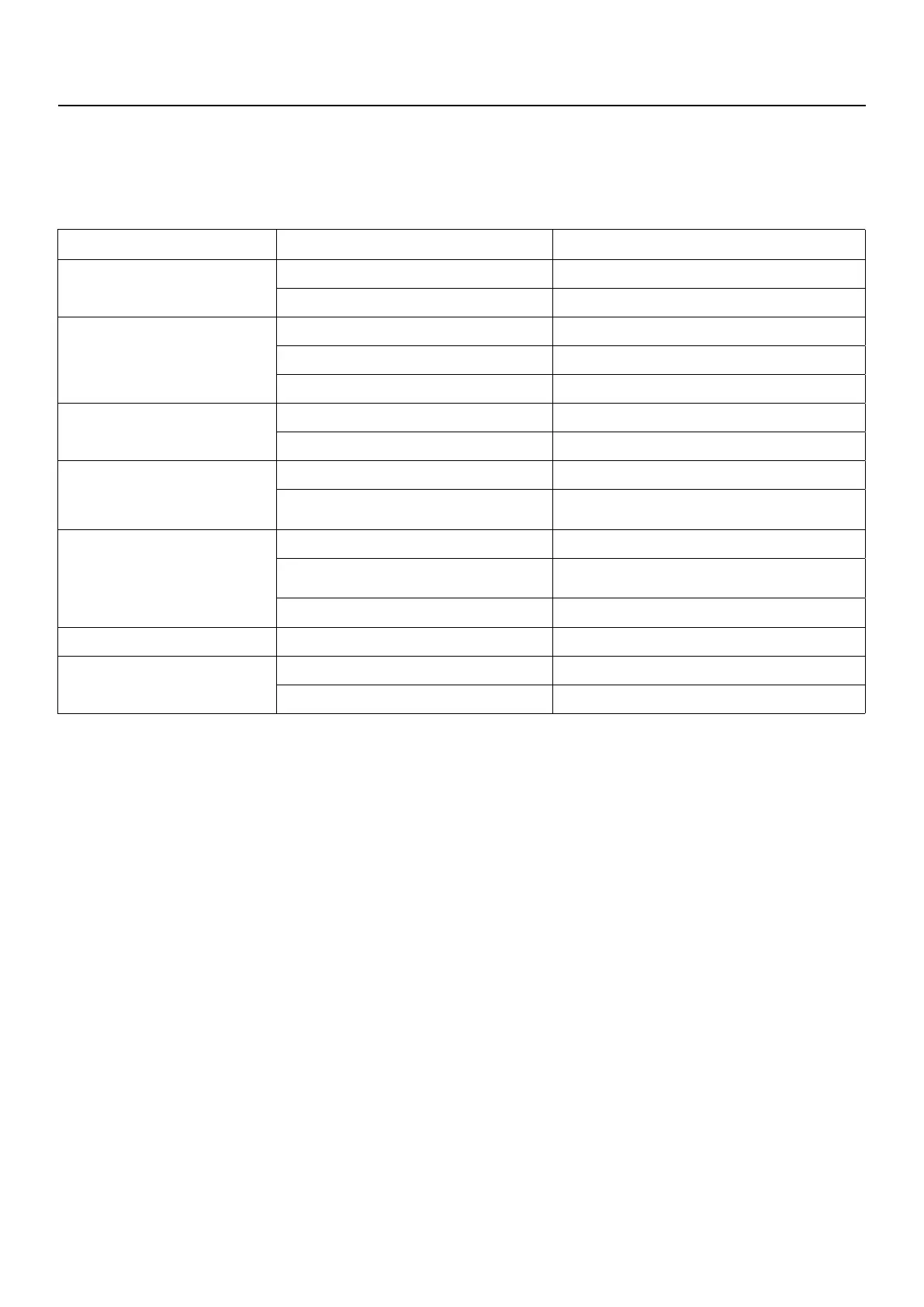

TROUBLESHOOTING

Key Description

1 Adjusting screw

2 Nut

3 Spring holder

4 Cover

5 Spring

6 Nut

7 Screw

8 Washer

9 Plate

10* Diaphragm

11 Plate

12* O-ring

13 Stem

Key Description

14* O-ring

15* Jet

16 Locking nut

17* “GACO” Ring

18 Thrust bearing

19 Spring

20 Safety valve

21* Pad

22* O-ring

23* O-ring

24 Plug

25 Body

26 Seat

PARTS LISTS

Type PS/79 (See Figure 3)

Loading...

Loading...