Safety and operating instructions

© Construction Tools GmbH | 33905146 01 | 2019-09-05

Original Instructions

27

NOTICE Total damage to the hydraulic attachment

Polluted hydraulic lines and connections may enable

sand, fragments of material and dirt to penetrate the hy-

draulic attachment and damage it completely.

u Clean the hydraulic lines and connections before

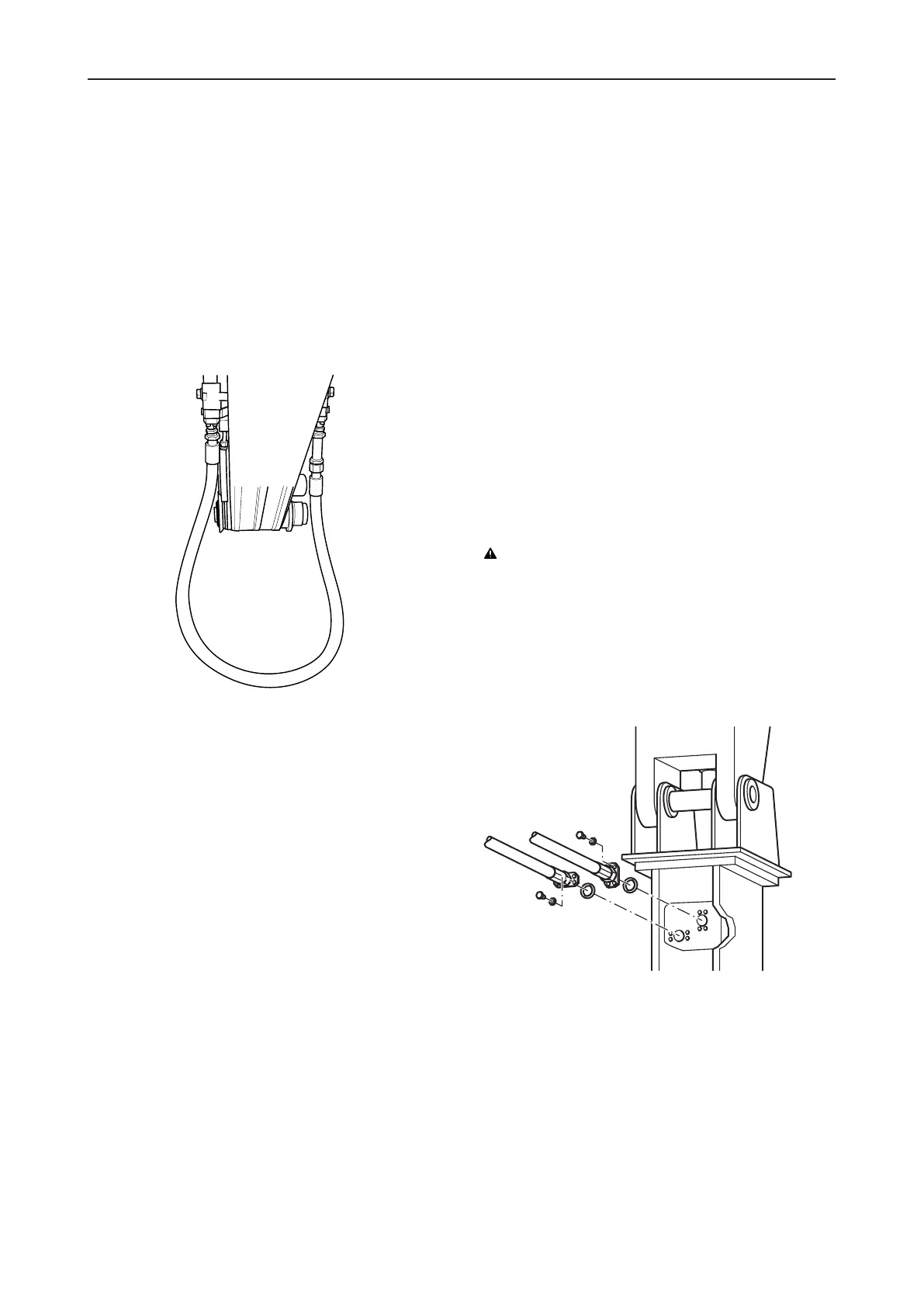

connecting the hydraulic hoses. Lay all hydraulic

hoses so that they are torsion-free.

n

Install the pressure and tank hoses.

n

Connect the pressure and tank hoses.

n

If no quick couplings are used, open the shut-off

valves in the installation at the boom.

n

Switch on the carrier.

n

Let the hydraulic oil run through the carrier oil filter for

approx. three minutes to make sure that the hoses

are clean.

n

Switch off the carrier.

n

Depressurise the hydraulic system according to the

manufacturer's safety and operating instructions for

the carrier.

n

If no quick couplings are used, close all shut-off

valves in the installation at the boom.

n

Disconnect the pressure and tank hoses.

5.4.2.1 Flange connection

n

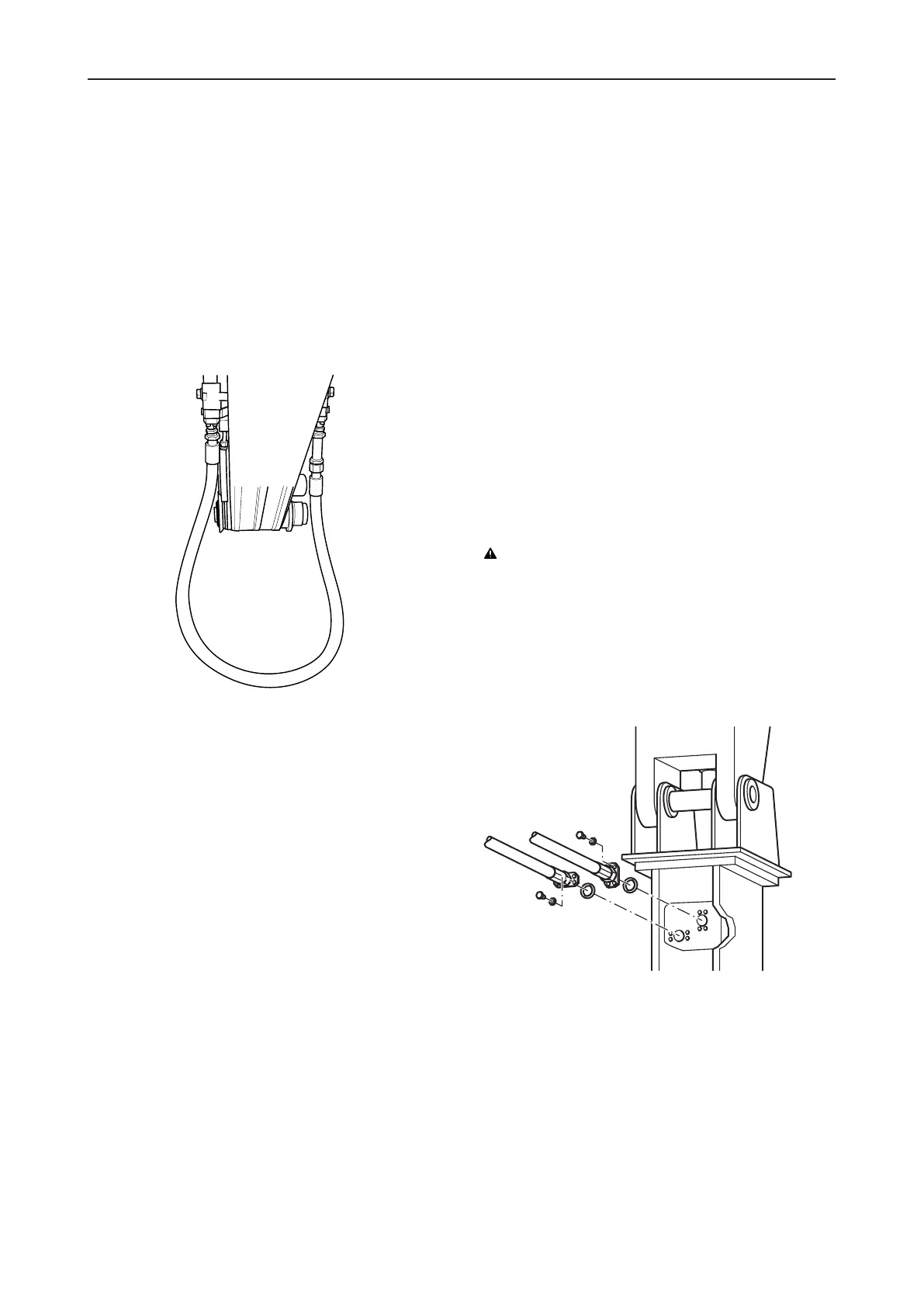

Unscrew the blind flanges from the ports »P« and

»T« and save them for future use.

n

Check that the ports and connections on the hy-

draulic breaker and/or on the hydraulic hoses are not

damaged.

n

Replace any damaged connections.

n

Grease the O-rings of the connection flanges with

ParkerO-Lube and install them.

n

Fit a pair of lock washers onto every fastening screw.

n

Attach the flange of the pressure hose to port »P«,

using the fastening screws and making sure it is tor-

sion-free.

n

Attach the flange of the tank hose to port »T«, using

the fastening screws and making sure it is torsion-

free.

WARNING Hydraulic hose flailing about

Pressurised hydraulic hoses will flail about if a bolted

connection comes loose or becomes loosened. A hy-

draulic hose flailing about may cause serious injuries.

u Tighten the fastening screws with the right tightening

torque.

Tightening torque (see chapter Bolt connections /

Tightening torques).

Loading...

Loading...