- 49 -

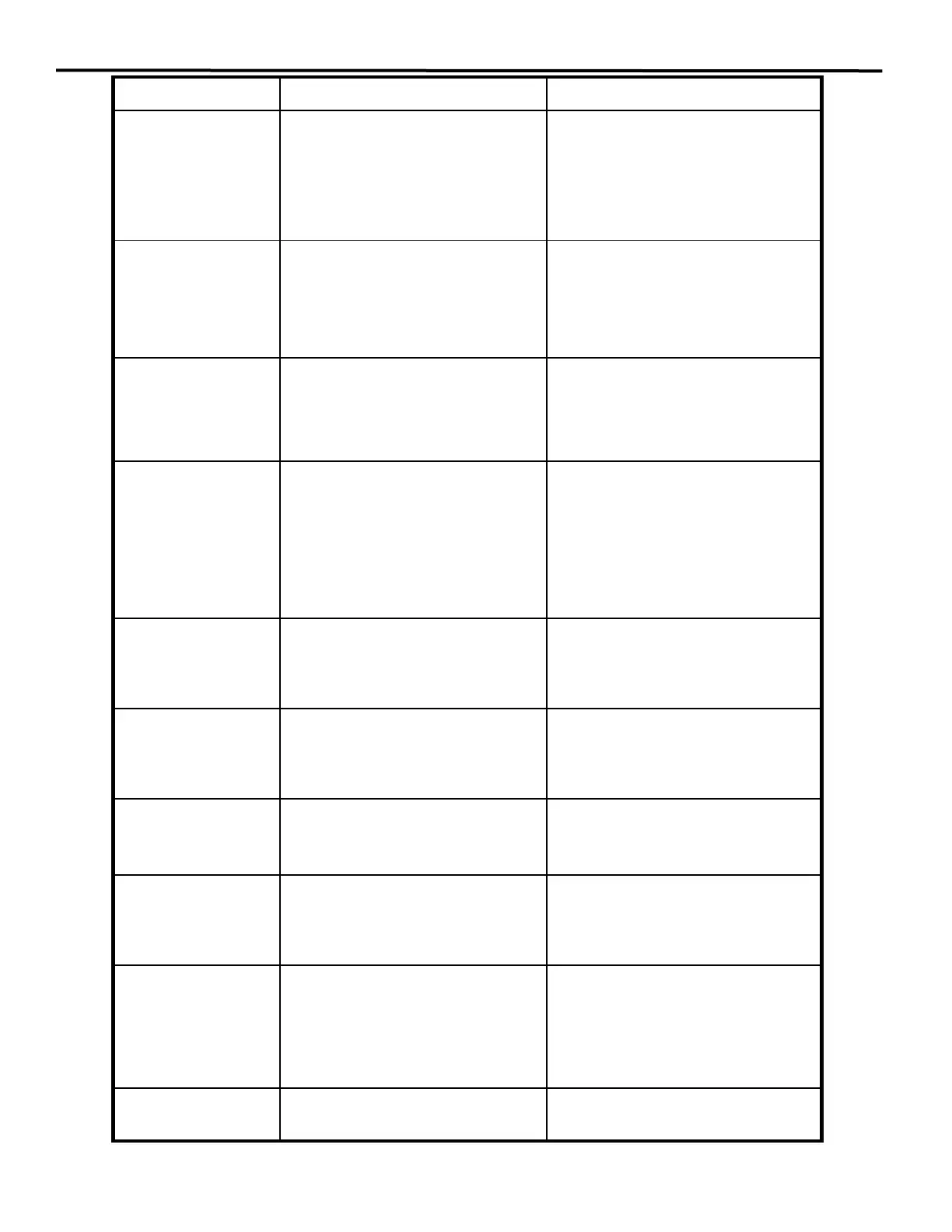

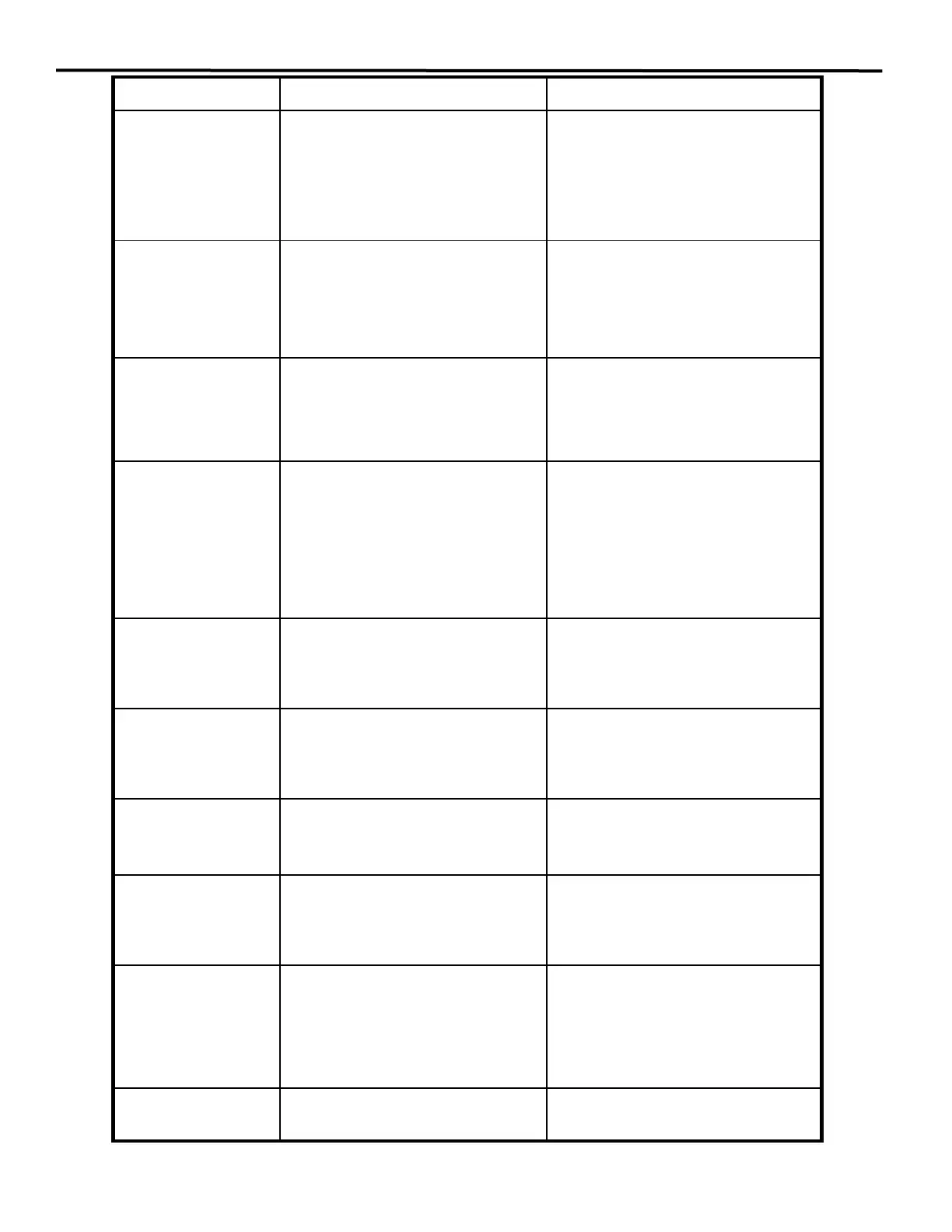

Trouble shooting guide

Problem Cause Correction

Upper thread breaks

1. The machine is not threaded correctly.

2. The thread tension is too tight.

3. The thread is too thick for the needle.

4. The needle is not inserted correctly.

5. The thread is wound around the spool

hol

der pin.

6. The needle is damaged.

1. Rethread the machine.

2. Reduce the thread tension (lower

nu

mber).

3. Select a larger needle.

4. Remove and reinsert the needle (flat

side).

5. Remove the spool of thread and rewind

the

thread.

6. Replace the needle.

Lower thread breaks

1. The bobbin case is not inserted

correctly.

2. The bobbin case is not threaded

correctly.

3. The lower thread tension is too tight.

4. Lint has collected in the bobbin case.

5. The bobbin is damaged and doesn’t

turn sm

oothly.

1. Remove and reinsert the bobbin case

and

pull on the thread. The thread should

pul

l easily.

2. Check both the bobbin and the bobbin

case.

3. Loosen the lower thread tension.

4. Clean the bobbin case.

5. Change the bobbin.

Skipped stitches

1. The needle is not inserted properly.

2. The needle is damaged.

3. The wrong size and/or type of needle is

used.

4. The presser foot is not attached

prope

rly.

1. Remove and reinsert the needle (flat side

towards the back).

2. Insert a new needle.

3. Choose a needle to suit the thread and

fabri

c being used.

4. Check the presser foot and attach

prope

rly.

Needle breaks

1. The needle is damaged.

2. The needle is not correctly inserted.

3. The needle clamp screw is loose.

4. The tension of the upper thread is too

tight.

5. Wrong needle size for fabric.

6. The pattern selector dial was turned

while the needle was still in the fabric.

7. Wrong presser foot is attached for stitch

patte

rn selected.

1. Replace with a new needle.

2. Reinstall the needle correctly (flat side

towards the back).

3. Tighten the needle clamp screw.

4. Loosen the upper thread tension.

5. Choose a needle to suit the fabric and

the

thread.

6. Always turn the hand wheel to lift the

nee

dle before turning the pattern selector

dia

l.

7. Select the correct presser foot.

Seams gather or

pucker

1. The thread tension is too tight.

2. The machine is not threaded correctly.

3. The stitch length is not correct.

1. Loosen the upper thread tension.

2. Rethread the sewing machine.

3. Readjust the stitch length.

Note: When sewing extremely light weight

fabrics, place a sheet of paper

unde

rneath the fabric.

Stitches form loops

underneath the fabric

1. The machine is not threaded correctly.

2. The bobbin case is not threaded

properly.

3. Needle/fabric/thread combination is

wrong.

4. Thread tension is wrong.

1. Rethread the machine.

2. Check the threading of the bobbin case.

3. The needle size must suit the fabric and

the

thread.

4. Correct the thread tension.

Uneven stitches,

uneven feed

1. Poor quality thread.

2. The bobbin case is not threaded

properly.

3. Fabric has been pulled.

1. Select a better quality thread.

2. Remove the bobbin case and rethread

and

reinsert correctly.

3. Do not pull on the fabric while sewing, let

it be taken in by the machine.

The machine is noisy

1. The machine needs to be lubricated.

2. Fluff or oil have collected on the hook or

nee

dle bar.

3. Poor quality oil has been used.

4. The needle is damaged.

1. Lubricate the machine.

2. Clean the hook and feed dog as

de

scribed.

3. Use only good quality sewing machine

oil

.

4. Replace the needle.

The machine jams or

does not work

1. Thread is caught in the hook race.

2. The machine is not plugged in.

3. Clutch knob is disengaged for the

bob

bin winding.

1. Remove thee upper thread and the

bob

bin case. Turn the hand wheel

ba

ckwards and forwards by hand and

remo

ve the thread remains. Lubricate as

de

scribed.

2. Plug the power cord into the power

source.

3. Engage the clutch knob.

The buttonhole stitches

ar

e not balanced

1. The stitch length is not suitable for the

fabric being sewn.

2. The fabric is being pulled or held back.

1. Adjust the stitch length.

2. Do not force the fabric for guiding.

Loading...

Loading...