17

Operation and Maintenance Instructions

Water Chemistry Parameters

A proper water treatment program is an essential part of routine maintenance to ensure the safe operation and longevity of this

unit. A water treatment company familiar with local water conditions should be consulted.

Any water treatment system used in the unit must be compatible with the unitʼs materials of construction. Although high quality

galvanized steel is used in most units, alternate materials of construction such as stainless steel (Type 304 or Type 316) are

increasingly being used.

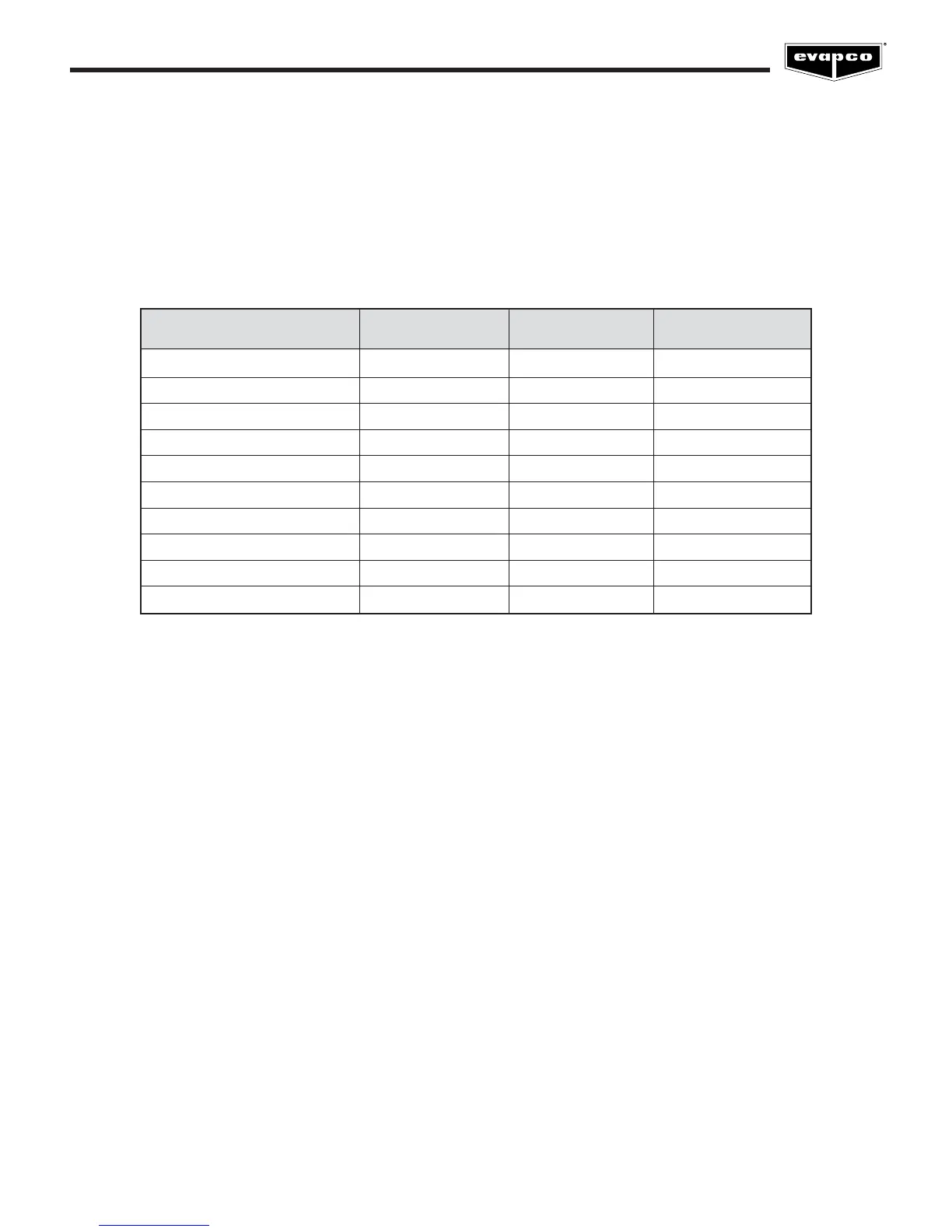

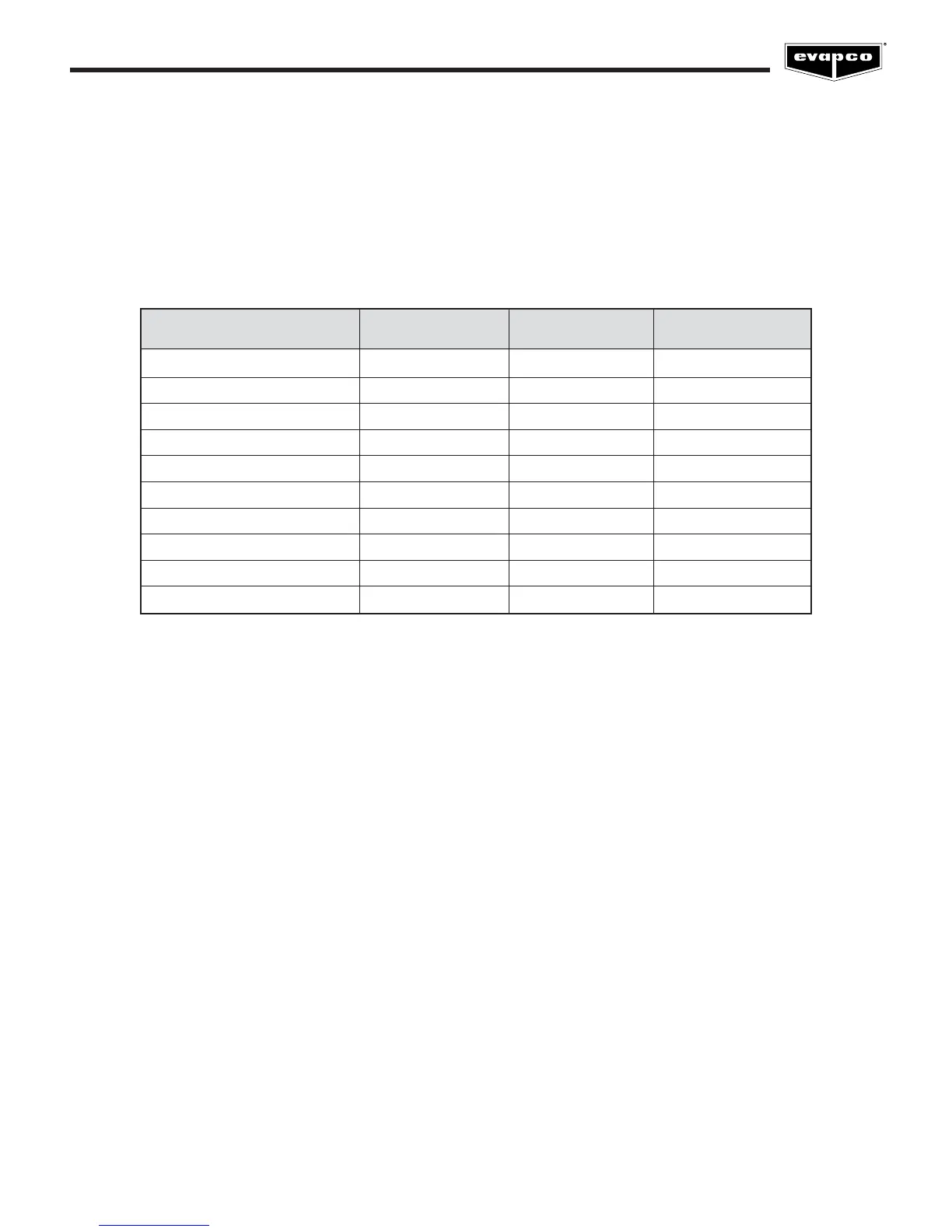

To control corrosion and scale, the recirculating water chemistry must be within certain ranges as shown in Table 4, or within the

limits provided by your local water treatment specialist.

Property G-235 Type 304 Type 316

Galvanized Steel Stainless Steel Stainless Steel

pH** 6.5 to 8.3 6.5 to 9.0 6.5 to 9.0

Hardness as CaCO3 (ppm) 50 to 300 < 300 < 300

Alkalinity as CaCO3 (ppm) 50 to 300 < 500 < 500

Total Suspended Solids (ppm)* < 25 < 25 < 25

Bacteria Count (cfu/ml) < 10,000 < 10,000 < 10,000

Conductivity (Micro-mhos/cm) < 2,400 < 3,500 < 5,000

Chlorides as Cl (ppm) < 250 < 400 < 4,000

Chlorides as NaCl (ppm) < 410 < 660 < 6,600

Sulfates (ppm) < 250 < 500 < 1,000

Silica as SiO2(ppm) < 150 < 150 < 150

* Based on standard EVAPAK

®

fill

** Galvanized steel units require routine passivation when the operating pH is 8.3 or higher to prevent “White Rust”.

See “Passivation” and “White Rust” sections for more details.

TABLE 4 – Guidelines for Recommended Water Chemistry*

Loading...

Loading...