8

Operation and Maintenance Instructions

Fan Shaft Sleeve Bearings – (4ʼ wide LSTA units only)

Lubricate the intermediate sleeve bearing(s) before unit start up. The reservoir should be checked several times during the first

week to ensure that the oil reserve is brought to full capacity. After the first week of operation, lubricate the bearing(s) every 1,000

hours of operation or every three months (whichever occurs first). High temperatures or poor environmental conditions may

necessitate more frequent lubrication. The oil reservoir consists of a large felt packed cavity within the bearing housing. It is not

necessary to maintain the oil level within the filler cup.

Use one of the following industrial grade, non-detergent mineral oils. Do not use a detergent based oil or those designated

heavy duty or compounded. Different oils may be required when operating at temperatures below 30°F continuously. Table 2

provides a short list of approved lubricants for each temperature range. Most automotive oils are detergent based and may not be

used. Detergent oils will remove the graphite in the bearing sleeve and cause bearing failure.

All bearings used on EVAPCO equipment are factory adjusted and self aligning. Do not disturb bearing alignment by tightening the

sleeve bearing caps.

Fan Belt Adjustment

The fan belt tension should be checked at start up and again after the first 24 hours of operation to correct for any initial stretch. To

properly adjust the belt tension, position the fan motor so that the fan belt will deflect approximately 1/2” when moderate pressure

is applied midway between the sheaves. Figure 1 and Figure 2 show two ways to measure this deflection. Belt tension should be

checked on a monthly basin. A properly tensioned belt will not “chirp” or “squeal” when the fan motor is started.

Table 1 - Location of Grease Lube Line Fittings for Belt Driven Units.

Please note, the removal of the fan screens is not necessary on forced draft units to access the extended lube line fittings.

Unit Description Location of Lube Line Fittings

Induced Draft Units: Located just beside the fan casing

6', 8', 8.5', 12', 15' and 17' wide access door

Induced Draft Units: Located inside the fan casing

All Others access door

LSTB Forced Draft Units Located on the front of the unit

LPT Forced Draft Units Located on the front of the unit

LSTA 4' Wide Forced Draft Units See Below

Ambient Temp Texaco Drydene Exxon

30°F to 100°F Regal R&O 220 Paradene 220 Terrestic 220

-25°F to 30°F Capella WF 32 Refrig. Oil 3G ------------------

Table 2 - Sleeve Bearing Lubricants

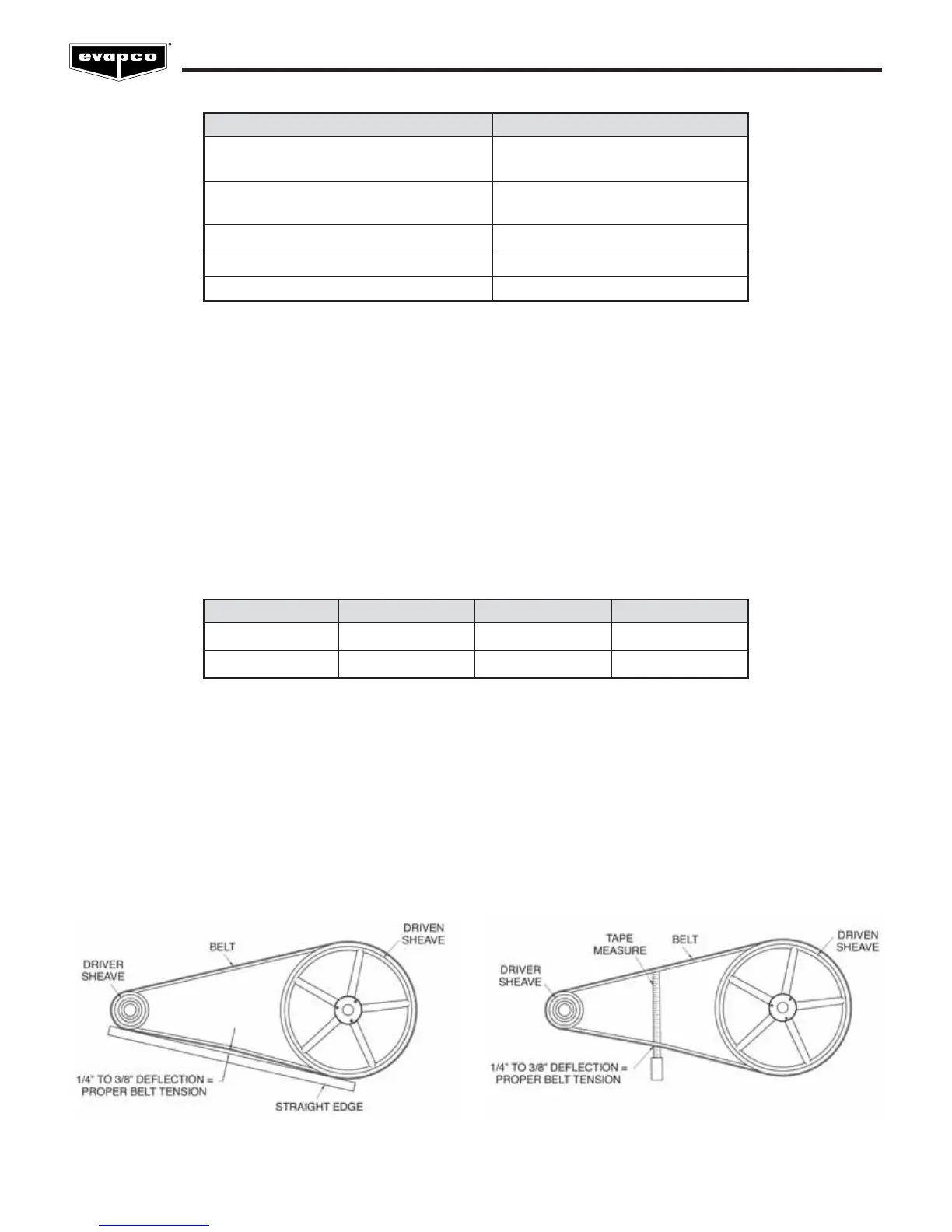

Figure 1 – Method 1

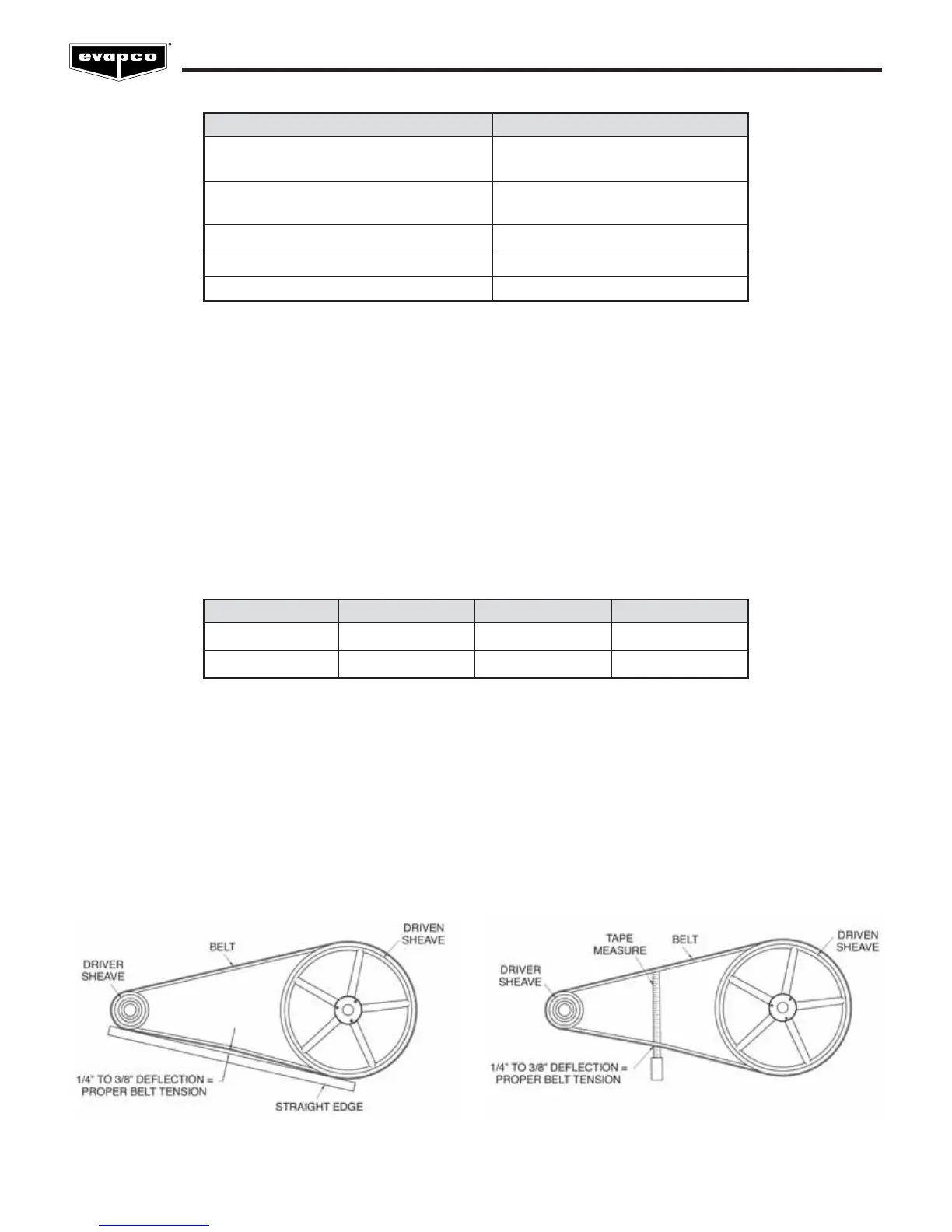

Figure 2 – Method 2

Loading...

Loading...