Changing wheel types

Consult your dealer or wheel/rim distributor before attempting any wheel

or fastener changes.

WARNING: Use only the same type and style wheels and

mounting hardware to replace original parts. Failure to do so

may result in an assembly that looks fine, but does not fit together

properly. This could possibly cause wheel or fastener failures which

could result in property damage, personal injury or death.

Note: Do not attempt to mix stud-piloted wheels or fasteners with

hub-piloted wheels or fasteners.

Note: Do not change from aluminum wheels to steel wheels or

vice-versa without changing the mounting hardware required or, with

flange-nut mounting systems, changing the hub and stud assembly.

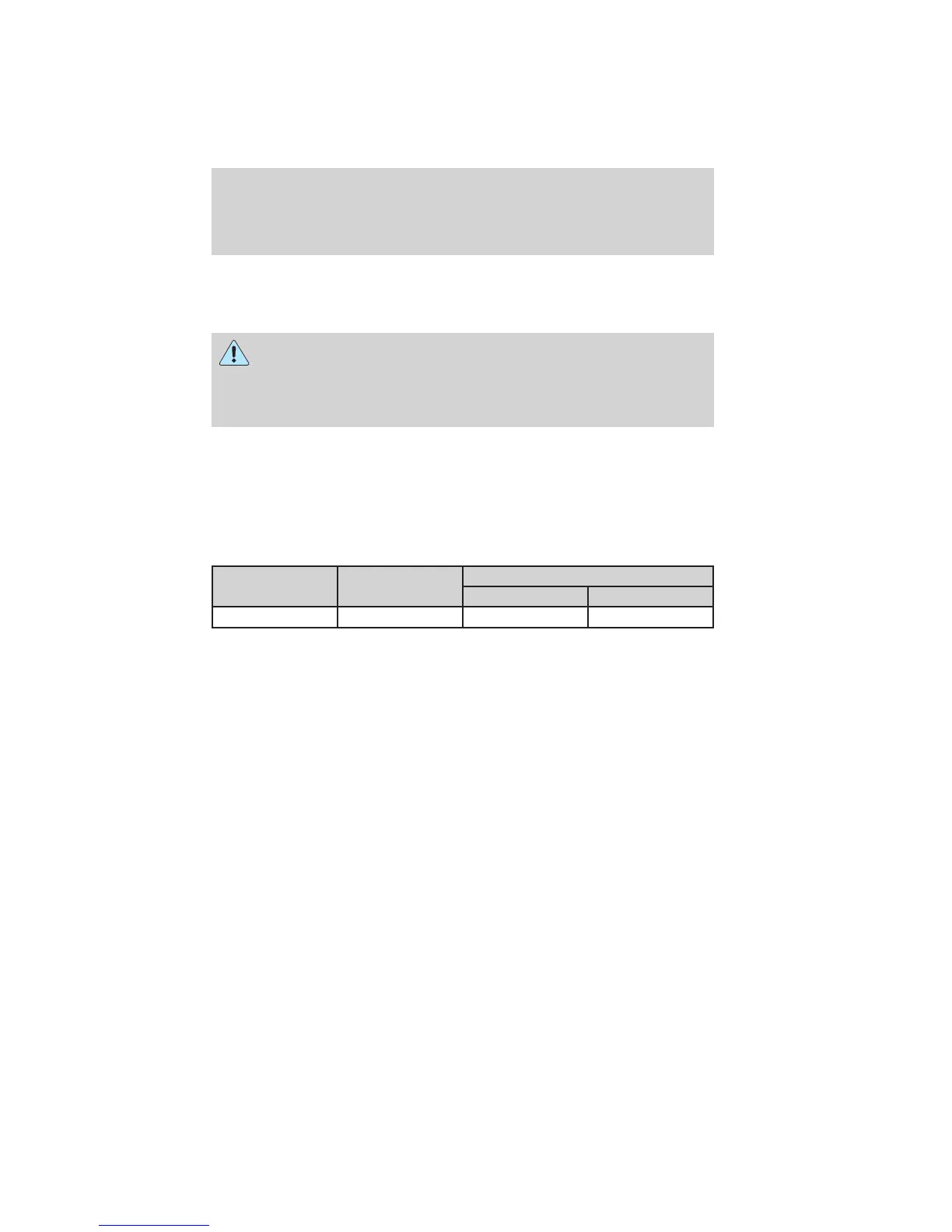

WHEEL NUT TORQUE

Size Nut mounting

Torque

ft-lb N•m

22 mm Flange 450–500 610–678

Note: Do not use lubrication on dry threads. Where excessive corrosion

exists, a light coat of lubricant on the first three threads of the stud bolt

is permitted. Keep lubricant away from:

• Hex nut and rim clamp contact surfaces.

• Cap nut ball face and ball seat on the disc wheel.

• Flange nut washer surface and flat on the disc wheel.

Maintenance and Specifications

237

2012 F-650/750 (f67)

Supplement, 2nd Printing

USA (fus)

Loading...

Loading...