----------PART

1 - ENGINE

SYSTEM----------

1

3

5

@

,

..

,,,

"-,

'

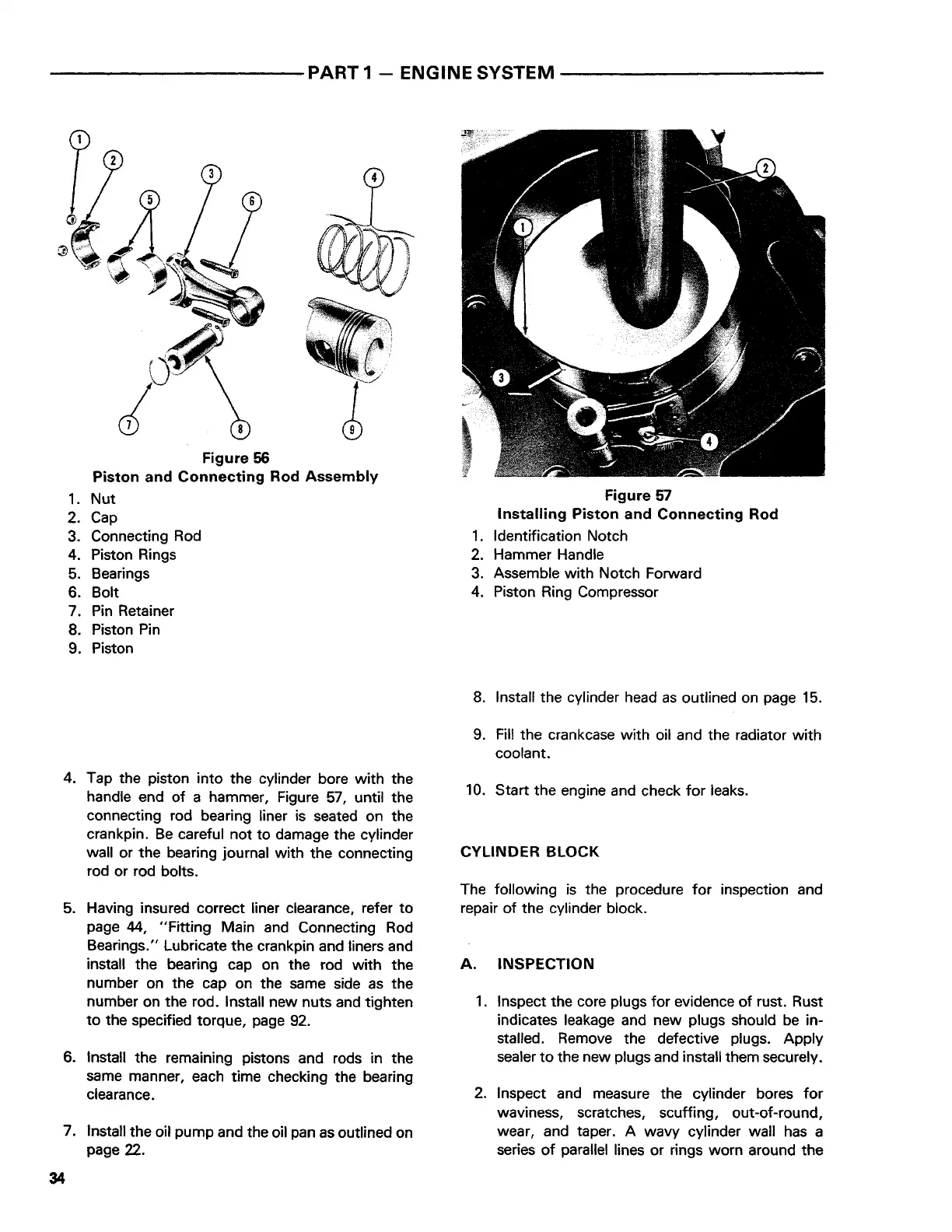

Figure

56

Piston and Connecting Rod Assembly

1.

Nut

2.

Cap

3. Connecting Rod

4. Piston Rings

5.

Bearings

6. Bolt

7. Pin Retainer

8. Piston Pin

9. Piston

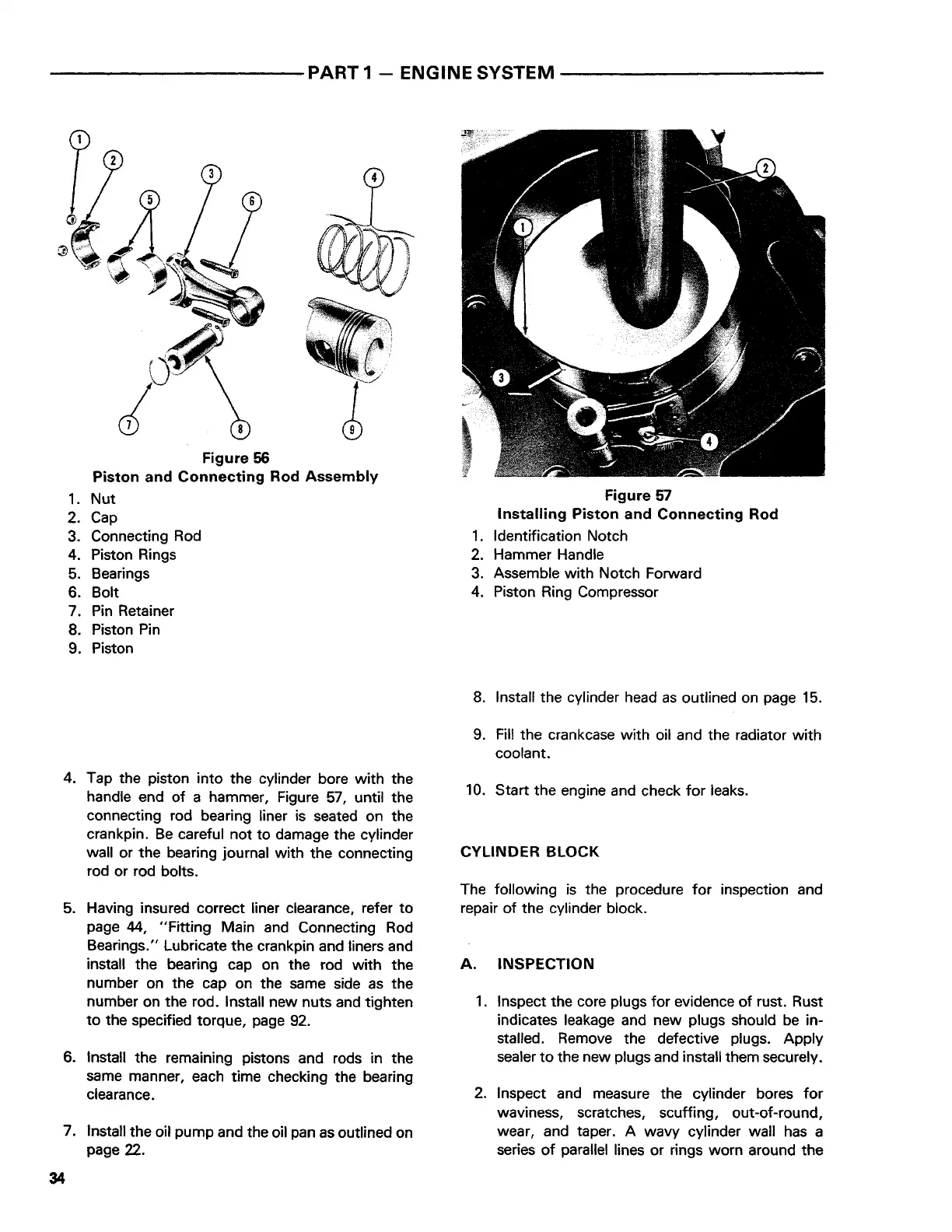

4. Tap the piston into the cylinder bore with the

handle end

of

a hammer, Figure

57,

until the

connecting rod bearing liner is seated on the

crankpin.

Be

careful not

to

damage the cylinder

wall or the bearing journal with

the

connecting

rod or rod bolts.

5. Having insured correct liner clearance, refer

to

page 44,

"Fitting

Main and Connecting Rod

Bearings." Lubricate the crankpin and liners and

install the bearing cap on the rod

with

the

number on the cap on the same side

as

the

number on the rod. Install new nuts and tighten

to

the specified torque, page 92.

6. Install the remaining pistons and rods in the

same manner, each time checking the bearing

clearance.

7. Install the oil pump and the oil pan

as

outlined on

page 22.

34

Figure

57

Installing

Piston

and

Connecting

Rod

1.

Identification Notch

2. Hammer Handle

3.

Assemble with Notch Forward

4. Piston Ring Compressor

8.

Install the cylinder head

as

outlined on page

15.

9. Fill the crankcase with oil and the radiator

with

coolant.

10.

Start the engine and check

for

leaks.

CYLINDER BLOCK

The following

is

the procedure

for

inspection and

repair

of

the cylinder block.

A. INSPECTION

1.

Inspect the core plugs

for

evidence

of

rust. Rust

indicates leakage and new plugs should

be

in-

stalled. Remove the defective plugs. Apply

sealer

to

the new plugs and install them securely.

2. Inspect and measure the cylinder bores

for

waviness, scratches, scuffing, out-of-round,

wear, and taper. A wavy cylinder wall

has

a

series

of

parallel lines or rings worn around the

Loading...

Loading...