9 – 9

ATEX Instruction Manual GEA19513 – 03/2012

4700E and 4800E Series Electropneumatic Positioners

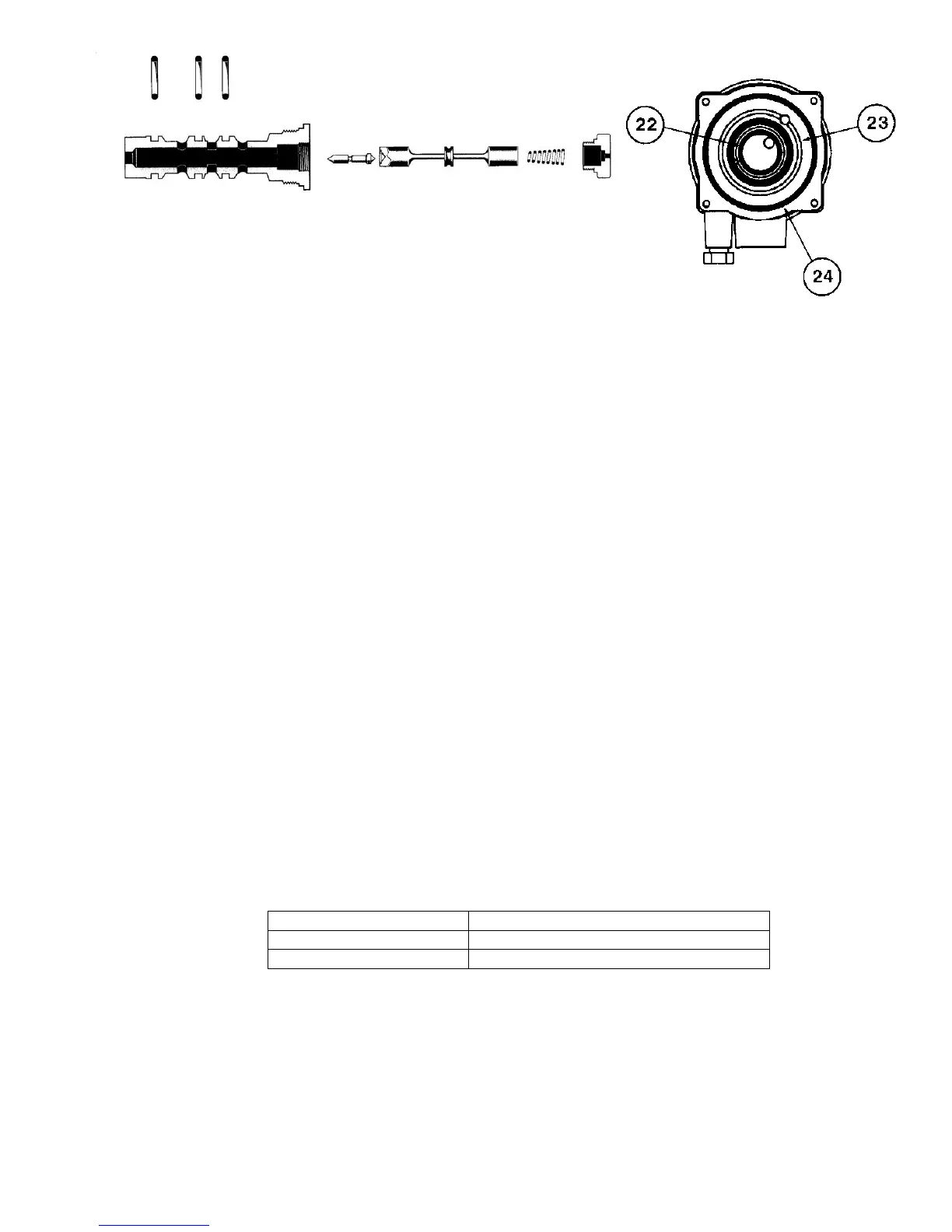

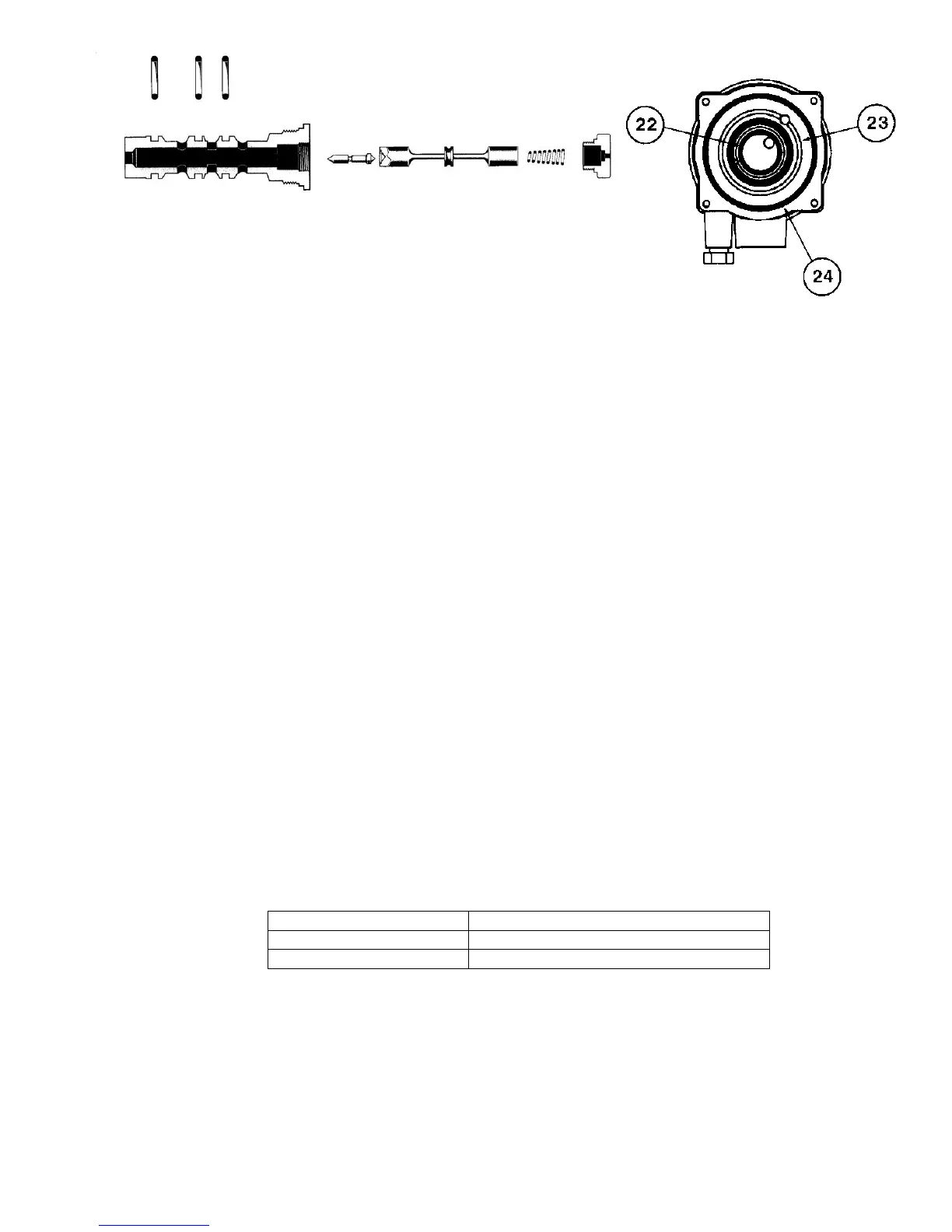

When replacing the I/P module, check the condition of the three 'O' rings

(22, 23 24) and replace them if necessary.

To proceed to a cleaning of the different sides of the enclosure to avoid

the deposits of dusts for instruments working in zones 20, 21 and 22.

Avoid contact of the apparatus with aggressive substances which could damage the metallic or plastic parts.

10.4. After maintenance activity

After doing any work on the device, check the cover (C) is fully screwed and the security cover screw is well locked (V).

11. SPECIAL CONDITIONS OF USE

11.1. For Intrinsic Safety and Flameproof

It is under the user responsibility to check once a year the gasket and in the event of damage to replace the

defective parts with manufacturer's replacement parts only.

For use in dusty hazardous areas, the user will have to proceed to a cleaning regularly the different sides of the

enclosure to avoid the deposits of dusts, the maximum thickness must be <5 mm. For safe operation, this can

be done only if the local conditions around the device are free of potentially explosive atmosphere.

The user will have to check the temperature increase on the positioner coming from the mechanical part in

contact with or through the process thermal radiation be less or equal than the temperature classification

allowed. This must be done in conformance with EN/IEC 60079-14 and / or national and local regulations

applicable for explosive atmospheres.

The user will proceed a cleaning of the device and mainly the plastic label with a wet rag to avoid any

electrostatic spark. For safe operation, this can be done only if the local conditions around the device are free

of potentially explosive atmosphere.

11.2. For Intrinsic Safety

The cable entry must have a protection level at least equal to IP54 according to EN/IEC 60529 standards.

For the housing with aluminum material, the user will have to determine the use of the device for group II

category 1 (zone 0) against potential inflammable source causing by sparks in the event of impact or friction.

The current source supply connected on the Model 4000 connectors must be certified for use in group IIC and

intrinsic safety loop approved. The entity parameters of the current source supply must be compatible with the

entity parameters of the Model 4000 I/P Converter described § 5.3.

11.3. For Flameproof

For ambient temperature greater than 70°C, the user must choice a cable entry and a cable compatible with:

Loading...

Loading...