88

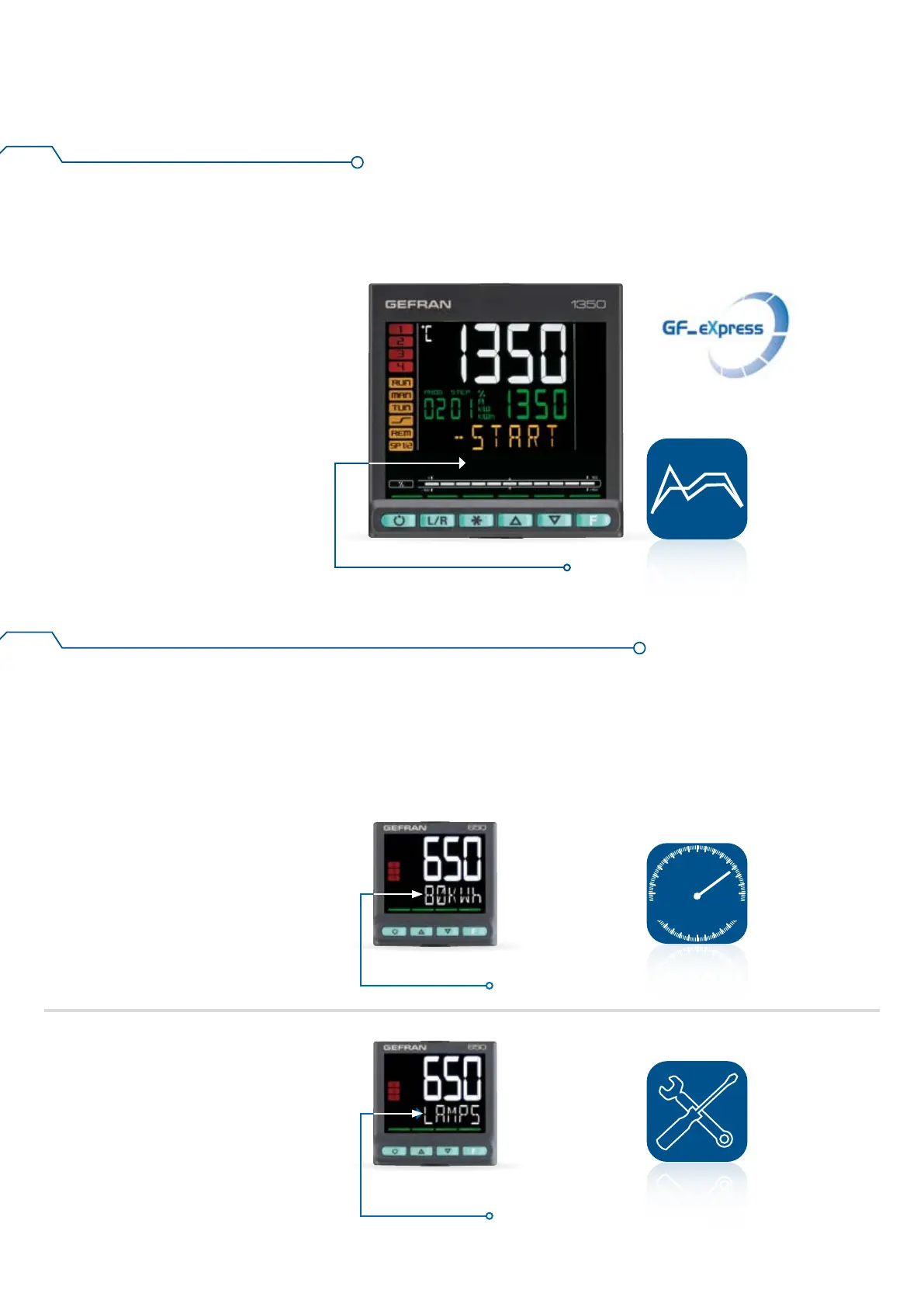

The various setpoint profiles with ramps, holds, trigger inputs and event outputs can be configured directly from the device keyboard or with

GF_eXpress in an easy to use by tracing the required profile.

Model 1350 (1/4 DIN) offers the widest and most complete operator interface in its category: a “dashboard” that simultaneously shows the

variable, setpoint, scrolling messages with 7 segments, step number, active program, and bargraph for program step times.

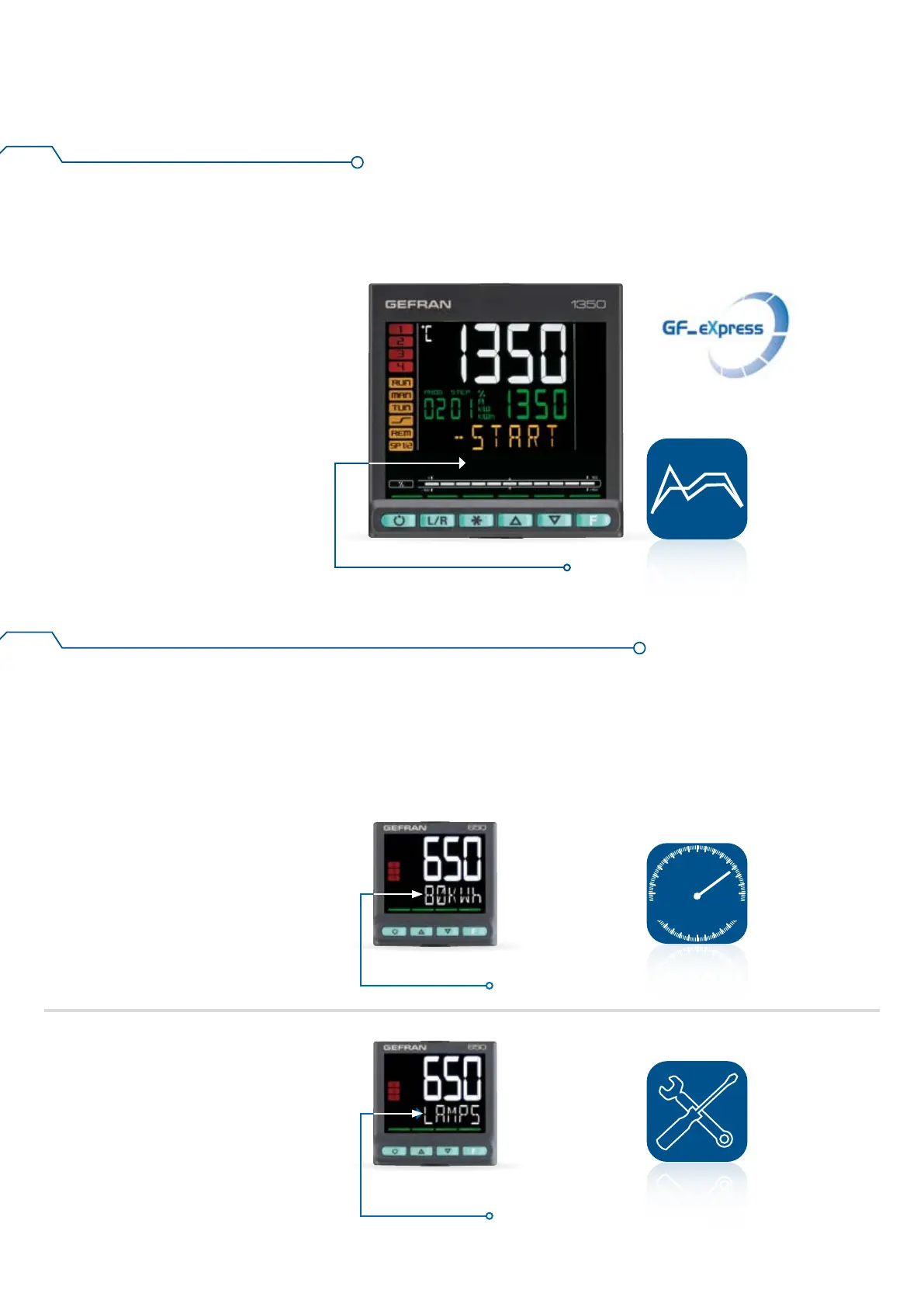

With the energy monitor function you can count and save the energy consumed by the process.

In case of deviations from average consumption, the controller signals with a physical output and configurable messages.

These functions accompany the preventive maintenance function, which monitors the life cycle of the actuators and Short Wave Infrared

(SWIR) lamps.

This lets you:

- predict any potential machine breakdowns

- schedule maintenance in advance

- prevent system shutdowns

- maximize machine up time and limit costly emergency shut downs

ENERGY MONITOR

Measures and monitors system

energy consumption.

Monitors and signals if system exceeds

expected values.

PREVENTIVE MAINTENANCE

Cycle counter and alarm messages

to monitor system cycles.

SETPOINT

PROGRAMMING

12 Segments with configurable

ramps and hold times

START COOKING PROGRAM

SETPOINT PROGRAMMER

PREVENTIVE MAINTENANCE AND ENERGY COUNTER

CONSUMPTION

80 KWH

WARNING:

CHANGE LAMP 5

80 KWH

Loading...

Loading...