7

SERVICE AND ADJUSTMENTS

ENGINE SPEED

The maximum engine speed was properly set

at the factory. Do not attempt to change this

setting. Operating the engine at high engine

speeds is dangerous and increases the risk of

personal injury or damage to the equipment.

If the engine is running too fast , take it to an

authorized service center for repair and adjust-

ment. CHANGING THE ENGINE’S MAXIMUM

GOVERNED SPEED WILL VOID THE ENGINE

WARRANTY.

Operating the engine at low engine speeds

with heavy loads may shorten the engine’s life.

Do not operate the engine below half throttle

except for idling.

The engine runs at a constant speed. This constant

operating speed is maintained by a mechanical, fly-

weight type, fixed speed governor. DO NOT try to

adjust the governed speed setting for the following

reasons:

• Operating the engine at high engine speeds is dan-

gerous and increases the risk of personal injury or

damage to the equipment.

• Operating the engine at low engine speeds with

heavy loads may shorten the engine’s life.

CARBURETOR ADJUSTMENTS

The carburetor of the engine is pre-set at the factory.

The carburetor should not be tampered with because

this will VOID THE EMISSION CONTROL SYSTEM

WARRANTY. If problems occur and the engine is

used at an altitude in excess of 5000 feet, contact the

nearest authorized dealer regarding high altitude set-

ting changes.

CHECKING/ADJUSTING VALVE TO ROCKER

ARM CLEARANCE

Without proper valve lash the engine may

require extreme force during starting. This can

be dangerous to the operator during manual

(pull) starts. Improper valve lash may also result

in premature wear of the engine.

After the first 50 hours of operation, remove the

rocker cover and check the valve to rocker arm clear-

ance.

When adjusting the clearance, the engine should be at

room temperature, and the piston should be at Top

Dead Center (TDC) of its compression stroke (both

valves are closed). The correct clearance is 0.05-

0.1mm (0.002-0.004 in.). Check and adjust the valve

to rocker arm clearance as follows:

1. Remove spark plug to avoid accidental starting.

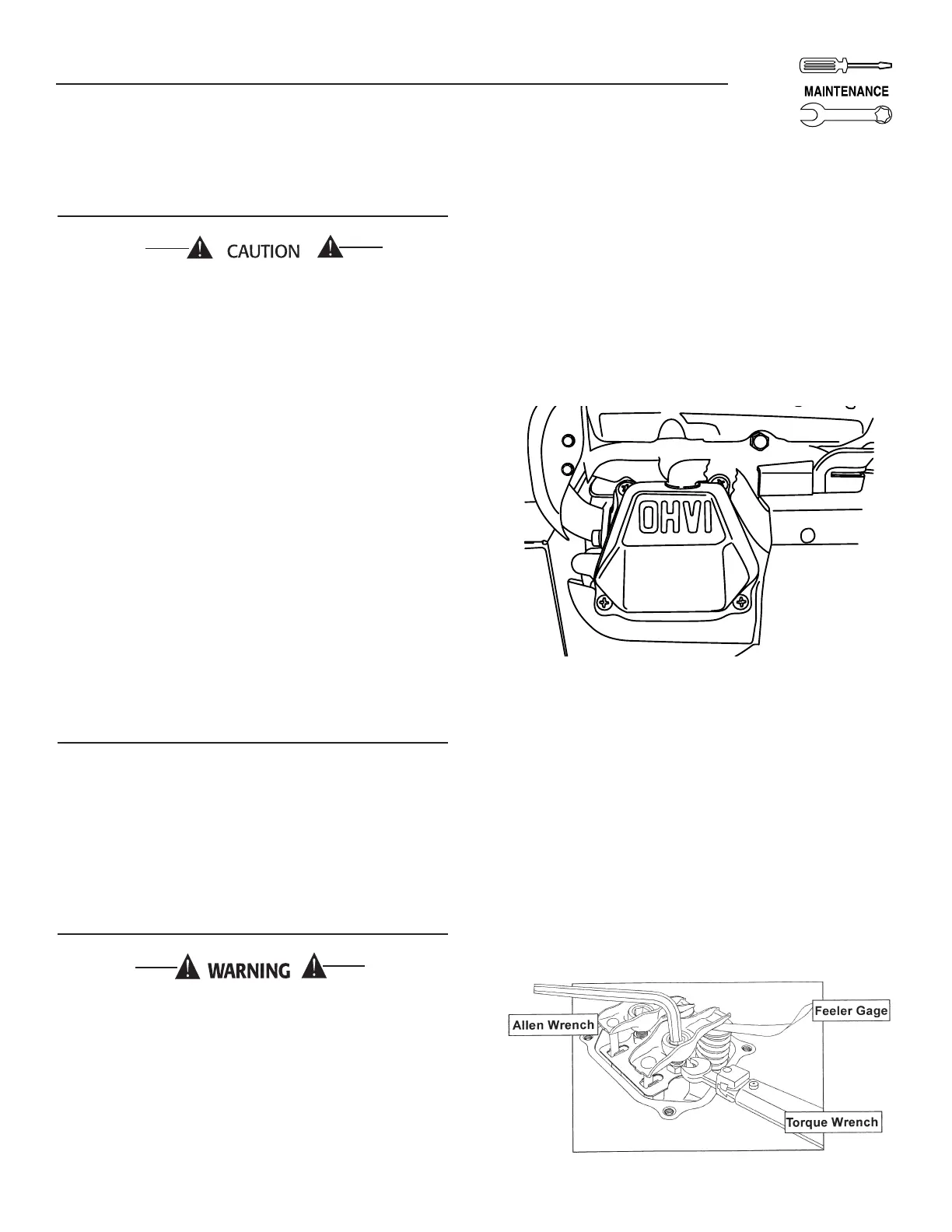

2. Remove the four (4) screws from the rocker cover

(Figure 10).

3. Remove the rocker cover and rocker cover gas-

ket.

Figure 10 - Removing the Rocker Cover

4. Rotate the engine using the recoil until the engine

is at top dead center. This can be determined

by watching the piston movement through the

spark plug hole. Rotate the engine until the piston

reaches its highest point. Both valves should now

be fully extended.

5. Check the valve clearance before making any

adjustments.

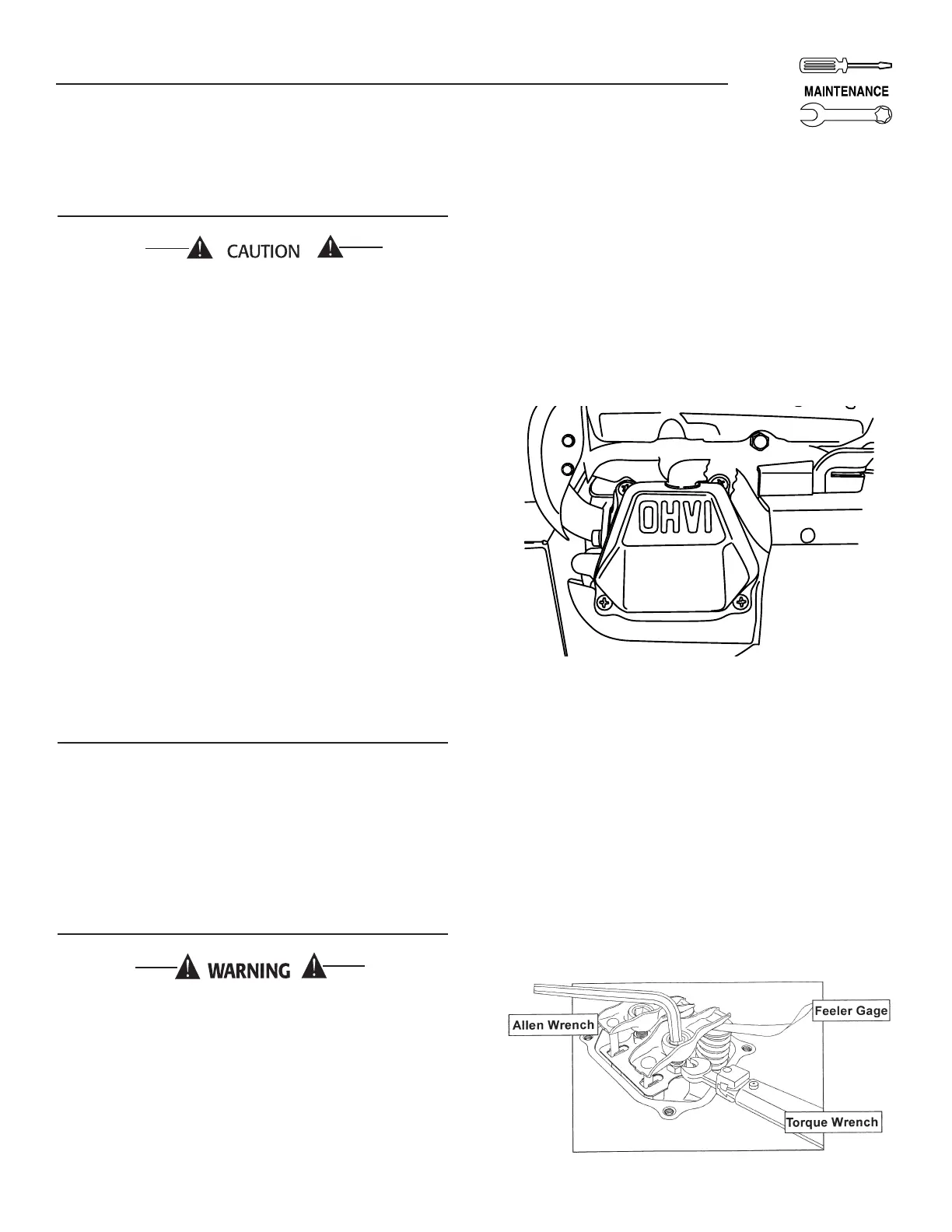

6. If the clearance is incorrect, loosen the rocker

arm jam nut. Using an allen wrench to turn the

pivot ball stud, check the clearance between the

rocker arm and the valve stem with a flat feeler

gauge (Figure 11).

Figure 11 - Adjusting Valve to Rocker Arm

Clearance

Section 3 — Maintenance

GH - 410 Engine

Loading...

Loading...