4

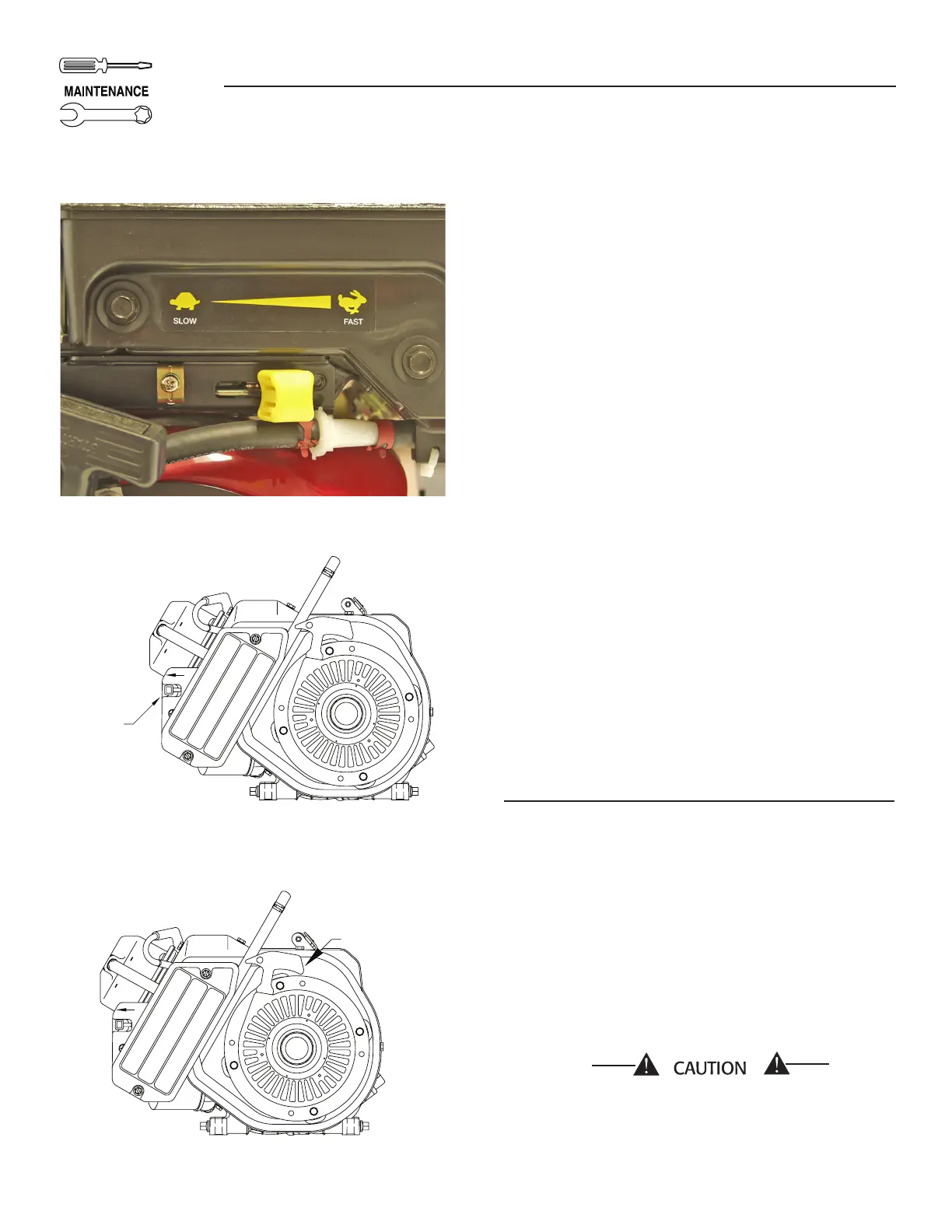

Figure 3 - Manual Speed Control

Figure 4 - Choke Position

W

IN

TER

-

SAE 5W

20 OR 5W

30

SUM

MER

-

S

AE 10W

30

SUR

FA

C

E OR

REPLA

CE.

C

HANG

E

O

IL EV

ER

Y 25

O

P

ER

A

TIN

G

HOU

RS

.

U

ND

ER DIR

T

Y/DU

STY

CO

NDITI

O

NS -

TO

CLE

AN

TA

P

G

E

NTL

Y ON

FL

AT

CLEAN

PA

P

ER ELEM

E

NT EVER

Y 25

O

PER

A

TING HO

U

RS -

M

O

RE

O

FTEN

C

RAN

KC

ASE

O

IL

AIR

CLEANE

R

M

AINTENAN

C

E

CHOKE

ST

AR

T

CHOKE

LEVER

Figure 5 - Recoil Handle

W

IN

TER

-

SAE

5W

20 OR 5W

30

SU

M

M

ER

- SAE 10W

30

SU

RF

A

C

E OR

REPL

A

CE.

CH

A

N

G

E

O

IL EVER

Y 25 OP

ER

AT

IN

G

H

O

UR

S.

UN

D

ER

D

IR

T

Y/D

U

STY CO

ND

ITI

O

N

S -

TO

CLEAN

T

AP GE

NTL

Y

O

N

FL

AT

C

LEA

N

PA

P

ER

ELEM

EN

T

E

VER

Y 25

O

PERA

TING HO

U

RS -

M

ORE OFTEN

C

RANK

C

ASE OIL

AIR

CL

EAN

E

R

M

AIN

TE

N

AN

C

E

CHOKE

ST

AR

T

RECOIL

HANDLE

3. Move the choke lever to the HALF CHOKE

POSITION, and pull the recoil handle (Figure 5)

two (2) times.

• If the engine STILL FAILS TO START, repeat

Steps 1-3.

4. Move the choke lever to the RUN POSITION by

sliding it to the right (away from the valve cover

and under the arrow).

5. Allow the engine to warm up for two (2) minutes

before using the equipment.

STOPPING THE ENGINE

1. Remove the load on the engine, and let it run for

30 seconds.

2. Turn off the engine by moving the RUN/STOP

SWITCH (Figure 2) to the STOP position.

3. Close the fuel shut-off valve, if so equipped.

LOW OIL PRESSURE SYSTEM

Some engine applications may be equipped with a low

oil pressure switch. The switch is a normally closed

type, but is held open by engine oil pressure during

cranking and running. Should engine oil pressure

drop below approximately 10 psi for any reason, the

switch contacts will close. With the switch contacts

closed, the following will occur:

• A low oil pressure indicator will turn on and glow

as power is available for its operation.

• If so equipped, the closure of the switch contacts

will connect the primary ignition circuit to ground.

Ignition will terminate, and the engine will shut

down.

INITIAL STARTUP

A delay built in the low oil pressure sensor allows oil

pressure to build during starting. The delay allows

the engine to run for about 10 seconds before sensing

oil pressure.

GENERAL MAINTENANCE

RECOMMENDATIONS

The owner/operator is responsible for making sure

that all periodic maintenance tasks are completed on

a timely basis; that all discrepancies are corrected;

and that the equipment is kept clean and properly

stored. Never operate a damaged or defective engine.

*

Disconnect the spark plug wire from the spark

plug, and place the wire where it cannot come

in contact with the spark plug before working

on this engine.

Section 3 — Maintenance

GSH-220 Engine

Loading...

Loading...